Titanium aluminum based powder metallurgy material for automobile engine exhaust doors and manufacturing method of titanium aluminum based powder metallurgy material

A technology of automobile engine and powder metallurgy, which is applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of inability to prepare fine-grained titanium-aluminum-based alloys, difficult to cut, and coarse structure, and achieves fine structure and small specific gravity. , the effect of uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

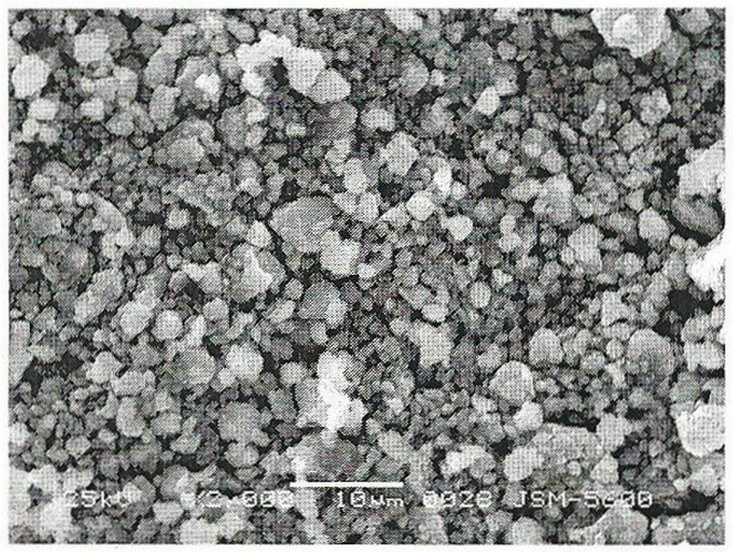

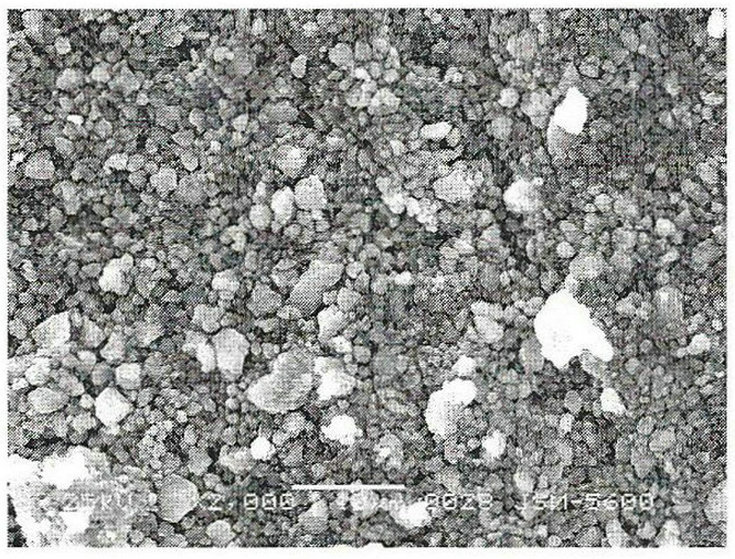

[0034] Embodiment 1: The method of mechanical alloying is adopted, that is, the mixed powder is refined and pre-alloyed by high-energy ball milling. Obtained including Ti, Al, Nb simple substance and Ti 3 Al, TiAl, Ti 2 Nanoscale grains including intermetallic compounds such as Al. By controlling the ball milling process, the content of the metastable phase of the titanium-aluminum intermetallic compound and the uncombined Al powder in the mixed powder is controlled. Under the condition of great plastic deformation, the powder continuously undergoes cold welding and crushing. With the extension of ball milling time, the particle size of the powder becomes smaller and more uniform. from figure 1 (Ti-45.7Al-5.4Nb component mixed powder) scanning photo of the ball mill shows that after 8 hours, some powder particles still maintain the original powder shape, and the average particle size is 40-50 μm. With the gradual increase of the ball milling time, the powder particles conti...

Embodiment 2

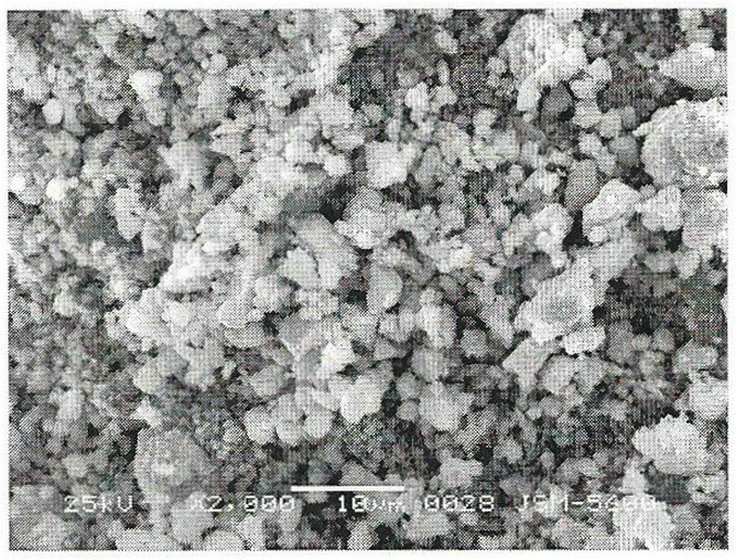

[0037] Example 2: Figure 6 to Figure 10 It is the shape of Ti-47.5Al-6.8Nb after ball milling, and the powder refinement law is similar to the experimental results of Ti-45.7Al-5.4Nb. Such as Image 6 , Figure 7 , Figure 8 with Figure 9As shown, as the ball milling time increases, the powder gradually refines. Since the powder agglomerates and combines during the ball milling process, the particle size of the powder observed by the scanning electron microscope, especially the particle size of the powder in the late stage of ball milling, is mainly the particle size of the powder cluster. Figure 10 It shows the TEM morphology and diffraction pattern of powder particles after high-energy ball milling for 30 hours, from Figure 10 Very fine powder particles can be clearly observed, and due to long-time ball milling, amorphous halos and intermittent polycrystalline rings appear in the diffraction pattern, which indicates the existence of amorphous and nanocrystalline.

Embodiment 3

[0038] Embodiment 3: as Figure 11 to Figure 14 As shown, they are the morphologies of Ti-45.7Al-6.2Nb, Ti-45.7Al-6.8Nb, Ti-47.5Al-5.4Nb and Ti-47.5Al-6.2Nb respectively after ball milling. The expected effect of refinement and alloying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com