Method for subsiding and purifying slime water by electrolytic process

A technology of coal slime water and electrolysis method, which is applied in the fields of coal slime water sedimentation purification, clear water coal preparation, and fine-grained strengthening, and can solve problems such as difficult sedimentation, high ash content, and affecting the effect of separation and washing of coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

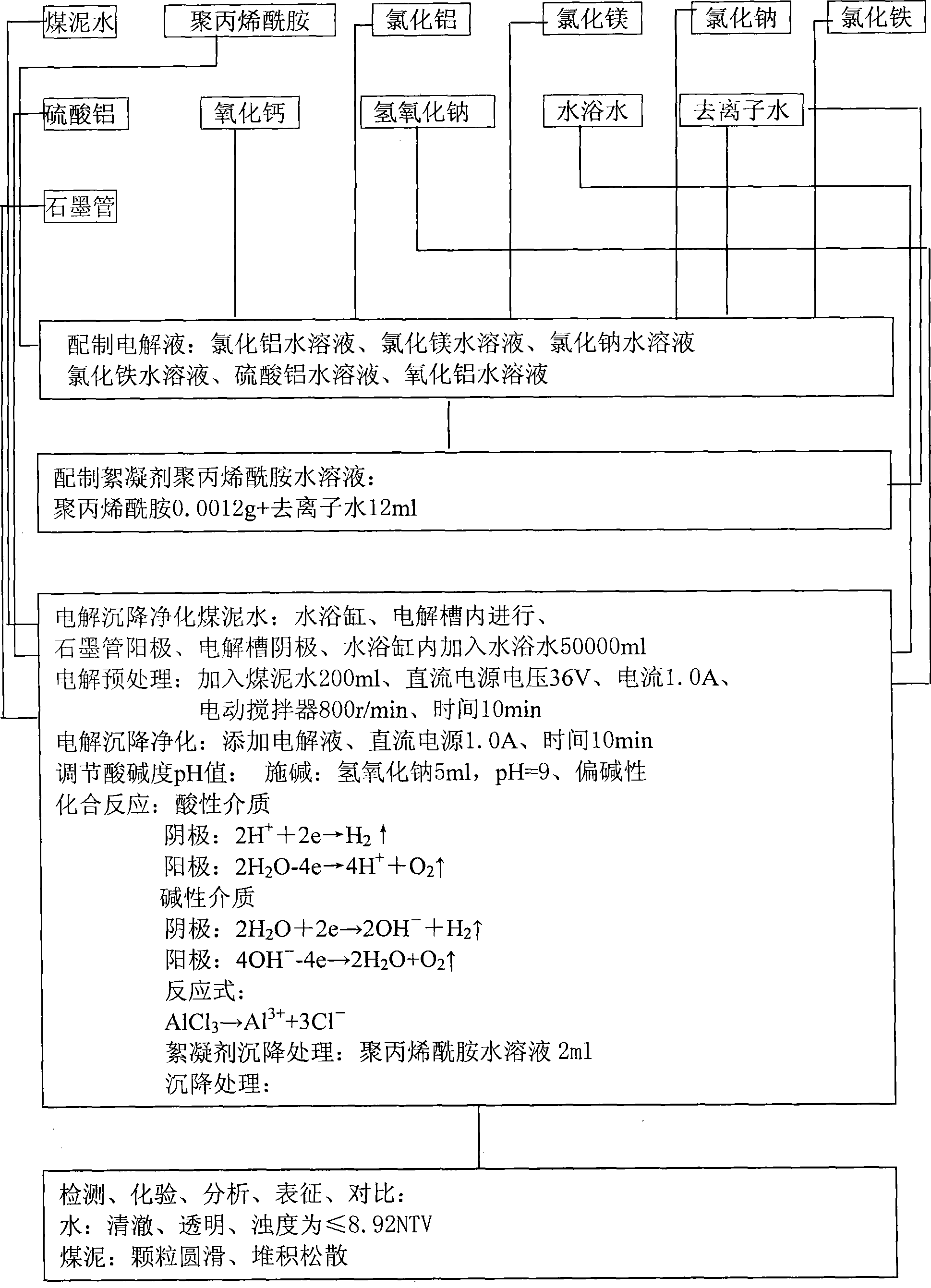

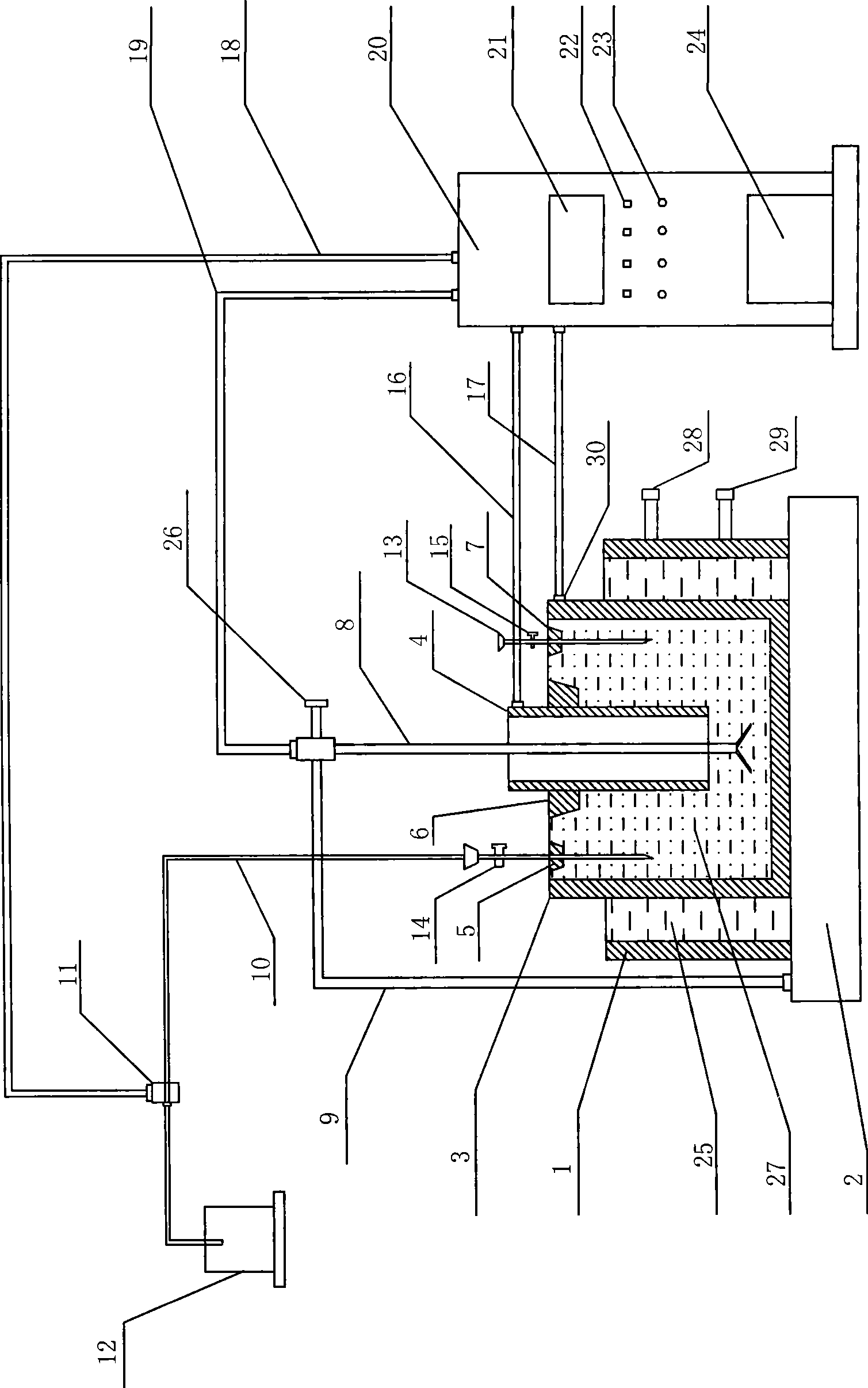

Method used

Image

Examples

Embodiment 1

[0135] Add the electrolyte solution from the addition funnel to the electrolytic cell: 5ml of magnesium chloride aqueous solution, stir at a constant speed for 5min, and mix it with the coal slime water; Then stir with an electric mixer for 10 minutes; then pump out the slime water electrolyte into the settling bottle, add 2ml of flocculant polyacrylamide into the settling bottle, mix with the slime water, and the coal slime will settle rapidly in the form of flocs and separate from the water.

Embodiment 2

[0137] Add electrolyte to the electrolytic cell from the addition funnel: 5ml of sodium chloride aqueous solution, stir at a constant speed for 5min, to make it mix with the coal slime water; then add 5ml of sodium hydroxide aqueous solution, stir at a constant speed for 5min, the pH value of the coal slime water mixture is 9, Slightly alkaline; then stir with an electric mixer for 10 minutes; then pump out the coal slime water electrolyte into the settling bottle, add 2ml of flocculant polyacrylamide into the settling bottle, mix it with the coal slime water, and the coal slime will settle rapidly in the form of flocs, and the water will separate.

Embodiment 3

[0139] Add electrolyte solution from the addition funnel to the electrolytic cell: ferric chloride aqueous solution 5ml, stir at a constant speed for 5min to make it mix with the coal slime water; then add 5ml of sodium hydroxide aqueous solution, stir at a constant speed for 5min, the pH value of the coal slime water mixture is 9, Slightly alkaline; then stir with an electric mixer for 10 minutes; then pump out the coal slime water electrolyte into the settling bottle, add 2ml of flocculant polyacrylamide into the settling bottle, mix it with the coal slime water, and the coal slime will settle rapidly in the form of flocs, and the water will separate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com