Production process of pure amino acid chelate and use thereof

A technology of amino compounds and amino acids, which is applied in the field of amino acid chelate complexes, can solve problems such as the accumulation of sulfate anions or chloride anions and affect the health of the body, and achieve the effect of improving solubility, easy solubility, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

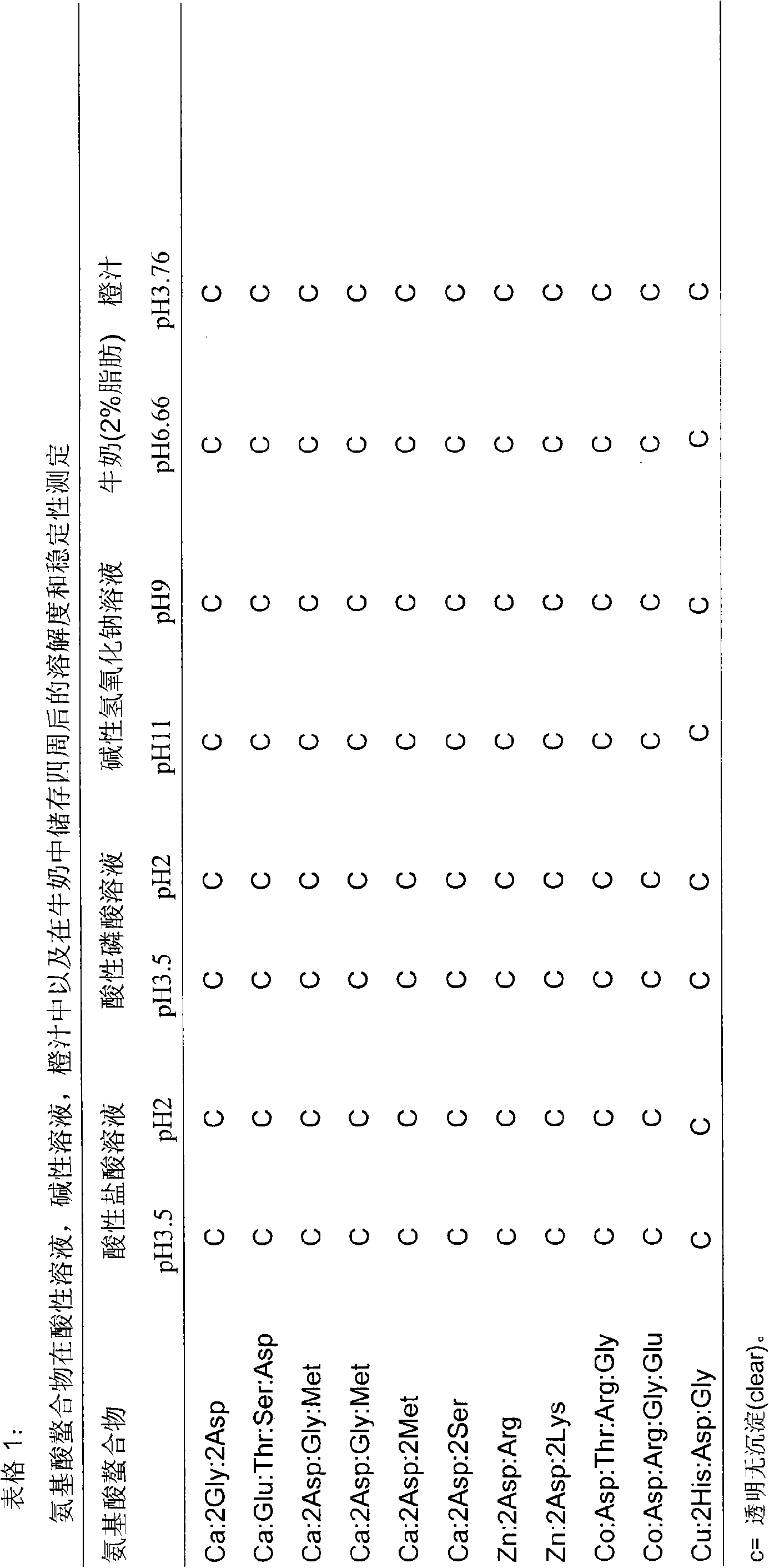

Embodiment 1

[0055] 3.7923 grams of aspartic acid was dissolved in 200 mL of distilled water, 2.1100 grams of calcium hydroxide was added to the solution and stirred for 20 minutes, when the pH value was 10.30, 4.3433 grams of glycine was added to the reaction solution and stirred for 30 minutes , the measured pH value is 8.75. Finally, 3.9098 g of aspartic acid was added to the reaction solution and the reaction mixture was stirred for 40 minutes to generate a transparent solution with a pH value of 6.83 and evaporated with a rotary evaporator (Tokyo Rikakikai Co., Ltd. Eyela Digital Water Bath SB-1000) The water was removed and dried to a solid with the aid of vacuum (Gardner Denver Welch Vacuum Technology, Inc., Skokie, IL, USA. Welch 1400). The pure amino acid chelate produced by the method is tested to have a calcium-amino acid ratio of 1:4 (Ca:2Asp:2Gly). Infrared spectroscopy (FT-IR) and nuclear magnetic resonance (NMR) analysis showed that the four amino acid ligands of the amino ...

Embodiment 2

[0057] Aspartic acid (3.7912 grams) was dissolved in 200 mL of water containing calcium hydroxide (2.1094 grams) and the reaction was allowed to proceed for 20 minutes. Once the pH is 10.30 and stable add 5.9866 grams of serine and agitate until the pH drops to 8.52 and stabilizes (approximately 30 minutes). Finally, 3.7862 g of aspartic acid was added to the reaction solution and the reaction mixture was stirred for 105 minutes. Finally, a transparent solution with a pH value of 6.89 was placed in a rotary evaporator to remove water, and then dried to a solid with the help of a vacuum pump. The ratio of calcium and amino acid in the pure amino acid chelate produced by the method is 1:4 (Ca:2Asp:2Ser).

Embodiment 3

[0059] 2.1135 grams of calcium hydroxide and 3.7985 grams of aspartic acid were added to 200 mL of water to react, stirring continuously and allowing the reaction to proceed for 20 minutes. When the pH of the reaction solution reached 10.30 and became stable, 6.7999 g of threonine was added and stirred continuously for about 30 minutes until the pH decreased to 8.50 and became stable. Then, 3.8012 grams of aspartic acid was added and stirred for 120 minutes. A transparent liquid with a pH value of 6.90 was dehydrated with a rotary evaporator and further dried under a vacuum pump. The final amino acid chelate product is a white powder with a calcium to amino acid ratio of 1:4 (Ca:2Asp:2Thr).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com