Electrochromism material and electrochromism device

A technology of electrochromic materials and electrochromic devices, which is applied in the direction of color-changing fluorescent materials, instruments, chemical instruments and methods, etc., can solve problems such as complex discoloration mechanisms, and achieve the effects of avoiding harm, improving stability, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

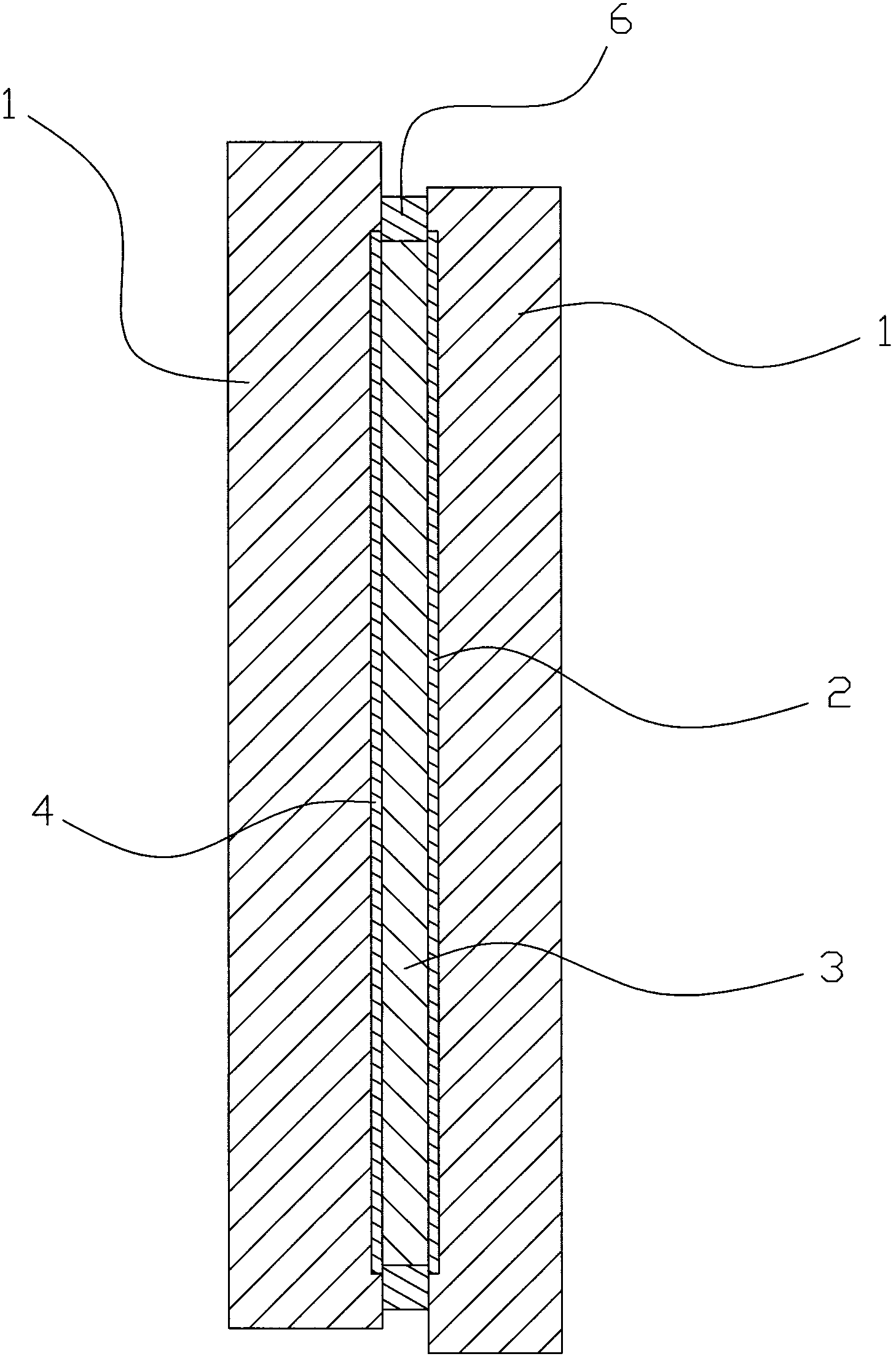

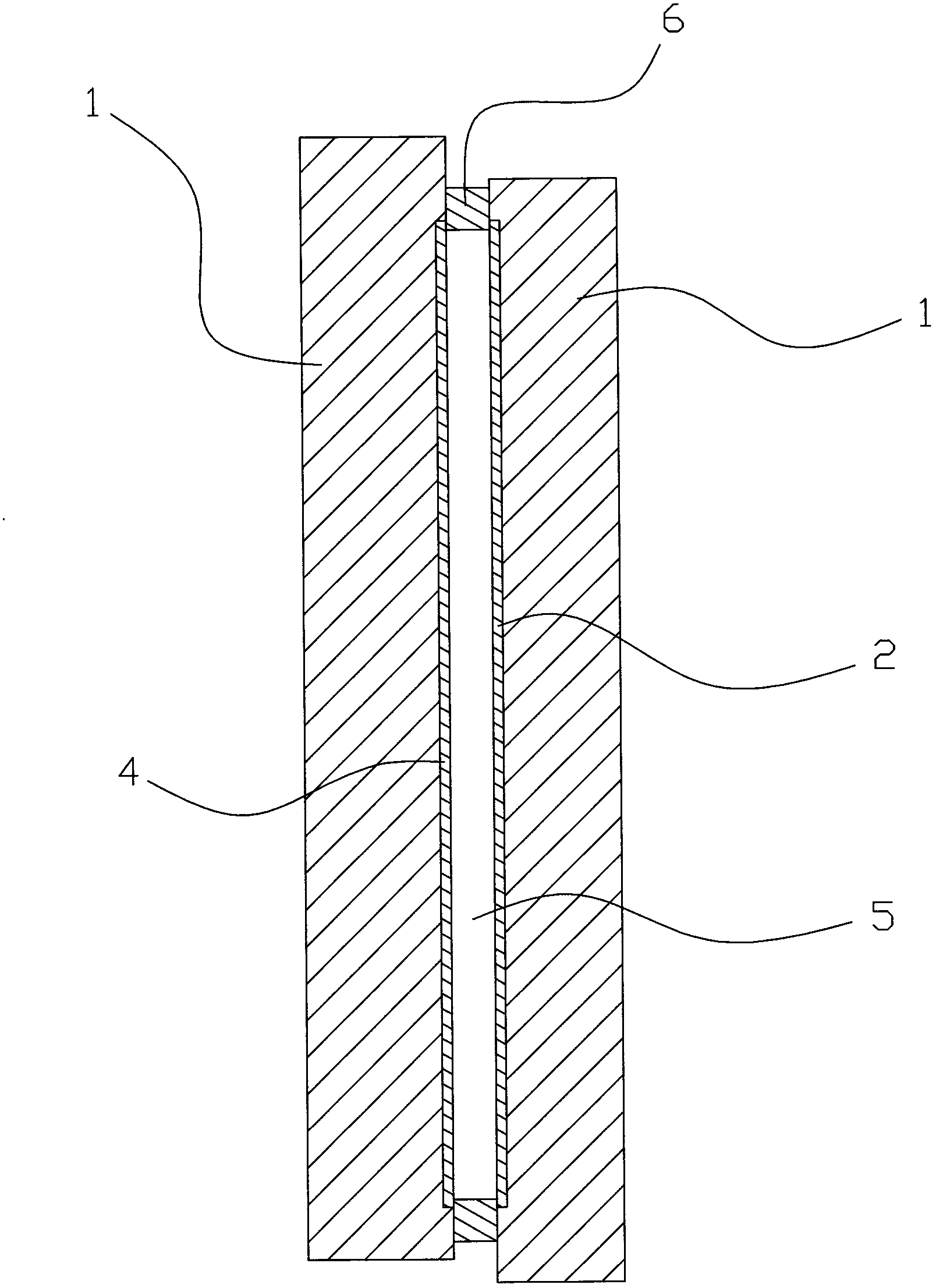

Image

Examples

Embodiment 1

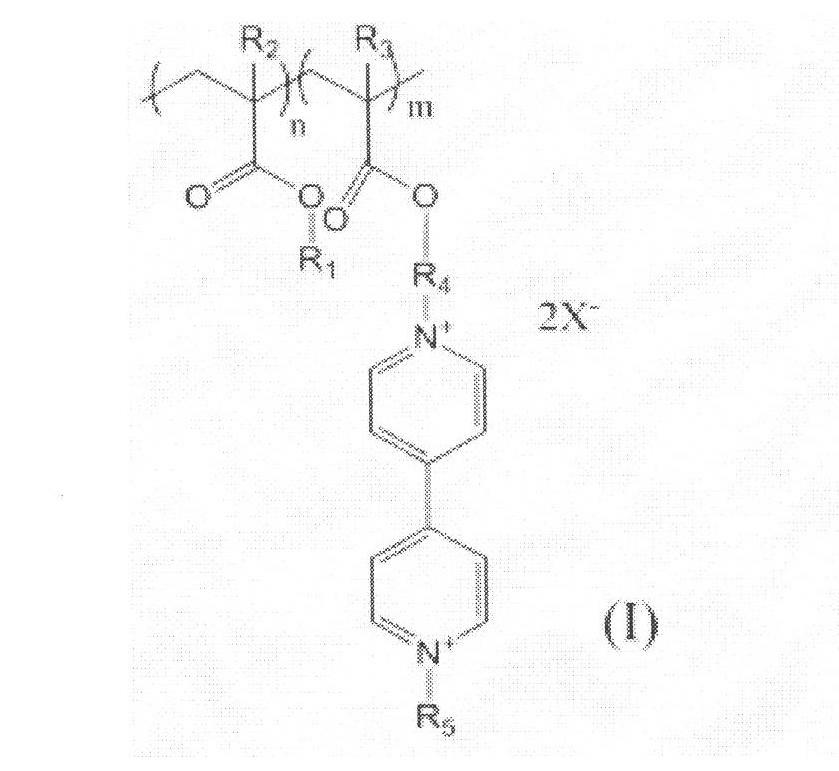

[0029] Embodiment 1, the preparation method of described cathodic electrochromic material (I) is: the 4 of 0.1mol, the 4'-dipyridine and the bromoethane of 0.1mol are dissolved in the acetonitrile solution of 200ml, heat reflux under agitation 12 Cool to room temperature and filter after 1 hour to obtain about 0.07 mol of 4-ethyl 4,4'-bipyridine derivatives; combine 0.05 mol of the above-mentioned monosubstituted 4,4'-bipyridine derivatives with 0.05 mol of methacrylic acid Ethyl bromide reacts to obtain 4,4'-bipyridine disubstituted derivatives containing double bonds; the above 0.01mol of 4,4'-bipyridine disubstituted derivatives containing double bonds and 0.1mol methyl methacrylate In the ethanol solution, add 0.02g of azobisisobutyronitrile as a free radical initiator to carry out copolymerization to obtain the cathodic electrochromic material (I).

[0030] The structural characterization of the above product is as follows: H 1 NMR (DMSO-d 6 ): δ8.95(4H), 8.84(4H), 4.51...

Embodiment 2

[0037] Example 2, preparation of cathodic electrochromic material, 0.1mol of 4,4'-dipyridine and 0.1mol of bromohexanol were dissolved in 200ml of acetonitrile solution, heated to reflux under stirring for 12 hours, cooled to room temperature and filtered, Obtain about 0.05mol of 4-hexyl 4,4'-bipyridine derivatives; react 0.02mol of the above-mentioned monosubstituted 4,4'-bipyridine derivatives with 0.02mol of bromoethylpropyl acrylate to obtain 4,4'-bipyridine disubstituted derivatives; the above 0.01mol 4,4'-bipyridine disubstituted derivatives containing double bonds and 0.05mol butyl methacrylate in ethanol solution, add 0.02g bipyridine The cathodic electrochromic material (I) is obtained by copolymerizing nitrogen diisobutyronitrile as a free radical initiator.

[0038] The structural characterization of the above product is as follows: H 1 NMR (DMSO-d 6 ): δ9.02(4H), 8.91(4H), 4.82(4H), 4.53(12H), 3.68~3.44(32H), 1.91(8H), 1.33~0.95(38H). It can thus be explained th...

Embodiment 3

[0045] Embodiment three, the making of cathodic electrochromic material (I), the 4 of 0.1mol, the 4 '-bipyridine and the bromobutanol of 0.2mol are dissolved in the 300ml acetonitrile solution, are cooled to Filtrate at room temperature to obtain about 0.07 mol of 4,4'-dihydroxybutyl 4,4'-bipyridine derivatives; mix 0.05 mol of the above-mentioned disubstituted 4,4'-bipyridine derivatives with 0.05 mol of methyl Bromomethyl acrylate is reacted to obtain 4,4'-bipyridine disubstituted derivatives containing double bonds; the above 0.01mol of 4,4'-bipyridine disubstituted derivatives containing double bonds and 0.04mol methyl methacrylate Add 0.02 g of azobisisobutyronitrile as a radical initiator to copolymerize the ester in ethanol solution to obtain the compound of cathodic electrochromic material (I).

[0046] The structural characterization of the above product is as follows: H 1 NMR: δ8.64(4H), 8.37(4H), 5.23, (1H), 4.89(4H), 3.68-3.44(16H), 2.03(4H), 1.35-0.98(26H). It c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com