End plate pressing component of redox flow cell galvanic pile

A technology of a flow battery and a pressing member, applied in the field of electrochemical energy storage, can solve the problems of low rigidity, difficulty in battery assembly, deformation, etc., and achieve the effects of reducing deformation, facilitating large-scale mass production, and enhancing reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

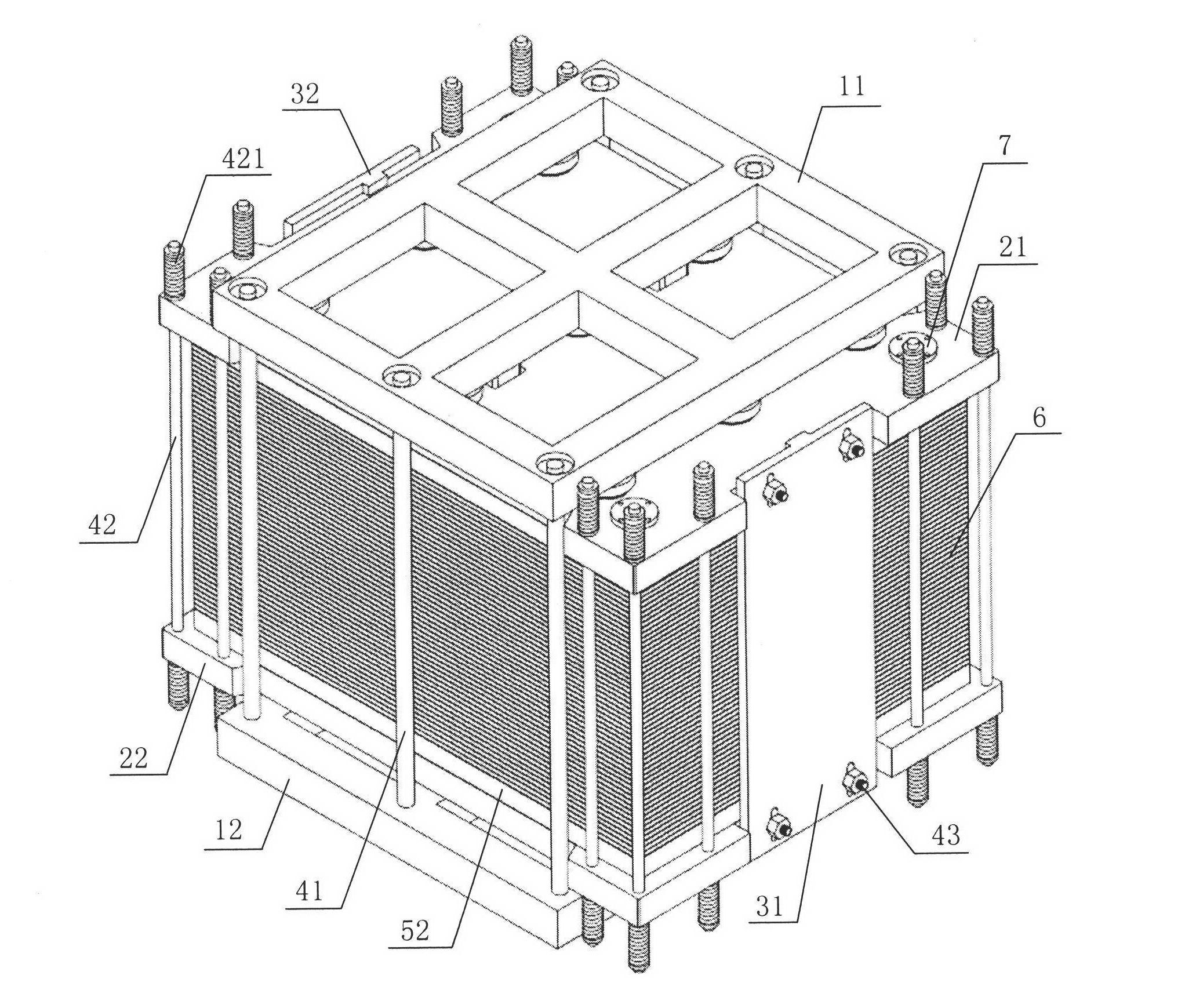

[0084] The end plate pressing member of the flow battery stack in the present invention is further described as follows:

[0085] Compression frame

[0086] Use square steel with a side length of 60 mm and a wall thickness of 4 mm to weld each other to form the main body of the compression frame; overall dimensions: length 720 mm, width 620 mm;

[0087] 2 guide columns are vertically welded on the bottom surface of the support beam at the centerline of the length direction of the compression frame, symmetrical to each other on both sides of the centerline of the width direction of the bottom surface of the compression frame, using stainless steel with a length of 50 mm, a width of 50 mm, and a height of 35 mm production;

[0088] 9 disc spring chassis are distributed in an array, welded to the bottom surface of the support beam in the length direction of the compression frame, made of stainless steel with a diameter of 75 mm, the inner diameter of the disc spring chassis is 6...

Embodiment 2

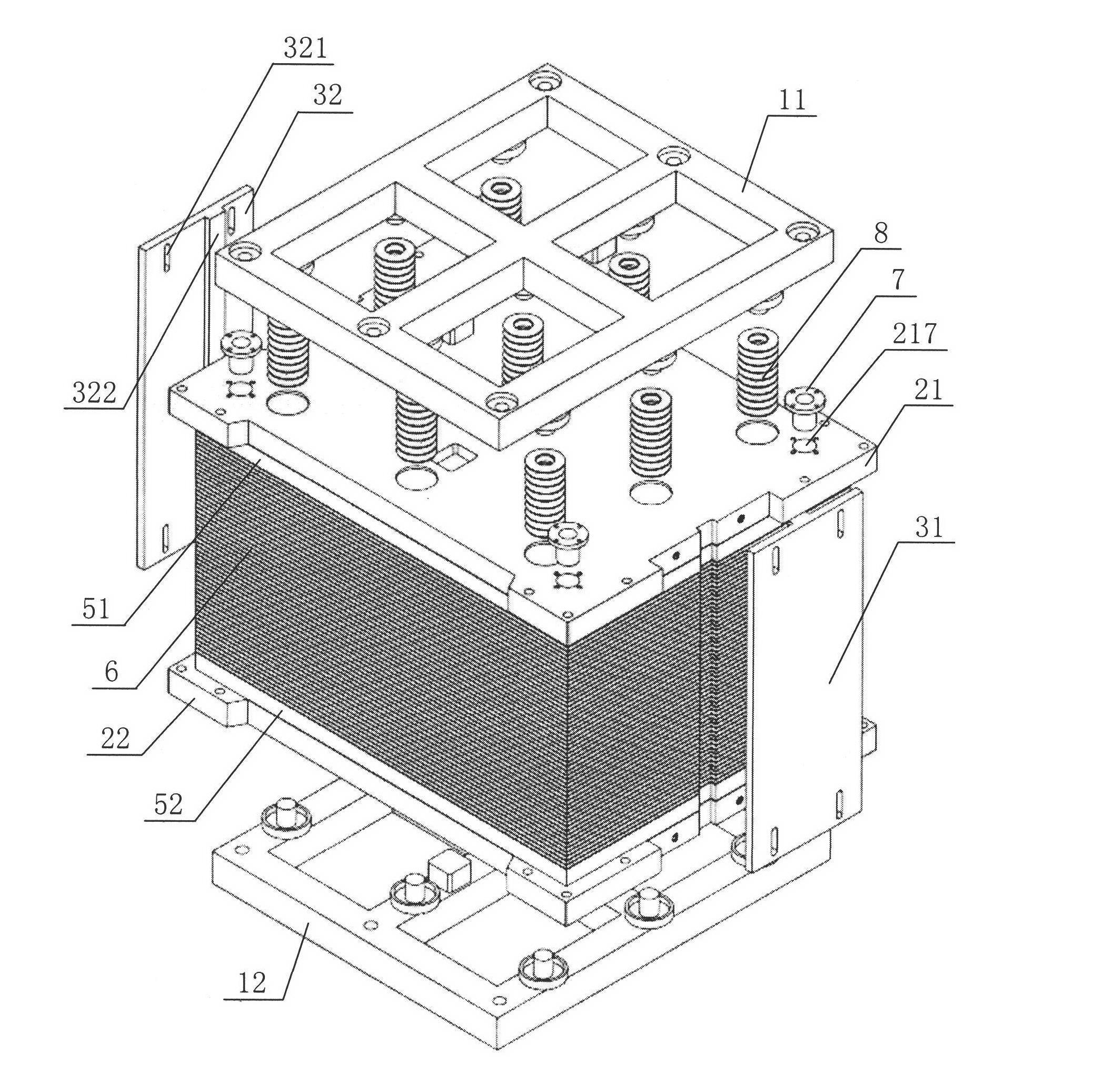

[0107] The end plate pressing member of the flow battery stack in the present invention is further described as follows:

[0108] Compression frame

[0109] Use square steel with a side length of 50 mm and a wall thickness of 8 mm to weld each other to form the main body of the compression frame; overall dimensions: length 720 mm, width 620 mm;

[0110] Two guide columns are vertically welded on the bottom surface of the support beam at the centerline of the width direction of the compression frame, symmetrical to each other on both sides of the centerline of the length direction of the bottom surface of the compression frame, using stainless steel with a length of 45 mm, a width of 45 mm, and a height of 25 mm production;

[0111] 9 disc spring chassis are distributed in an array, welded to the bottom surface of the support beam in the length direction of the compression frame, made of stainless steel with a diameter of 92 mm, the inner diameter of the disc spring chassis is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com