Low voltage contact assembly

A contact assembly, low-voltage technology, applied in the direction of contacts, contact meshing, electrical components, etc., can solve problems such as current imbalance, uneven pressure distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

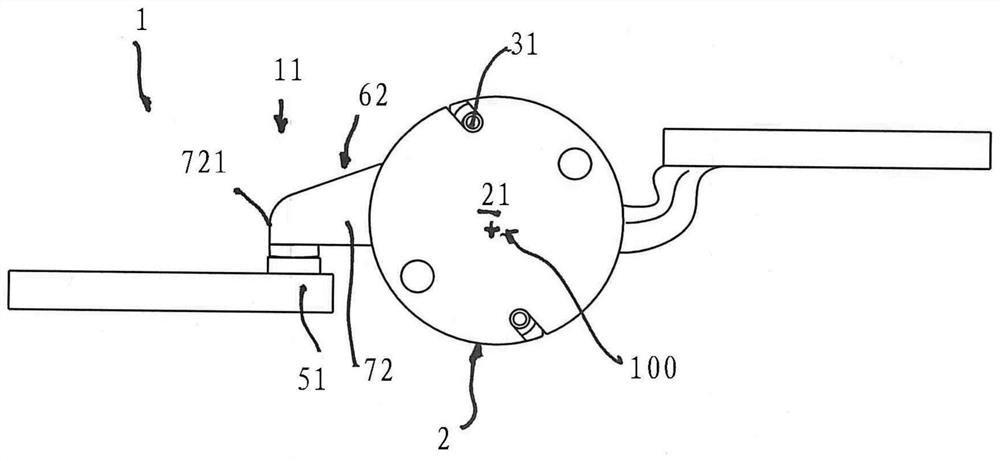

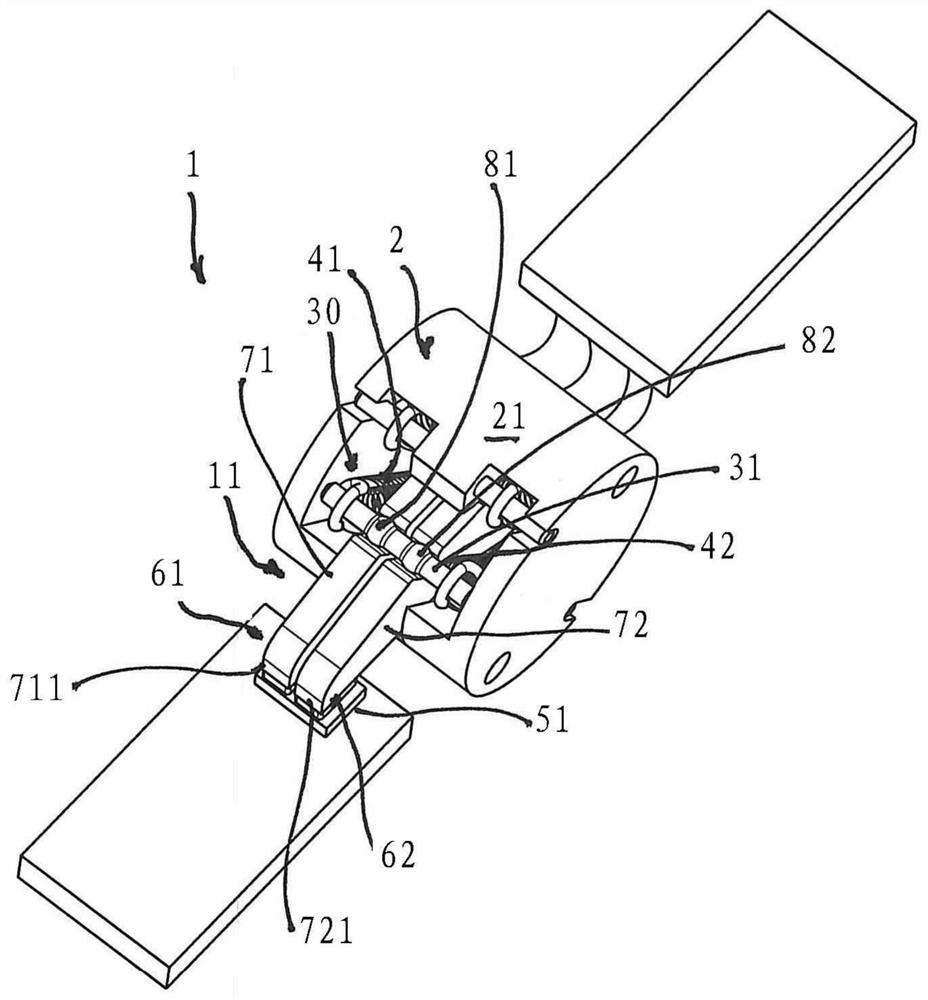

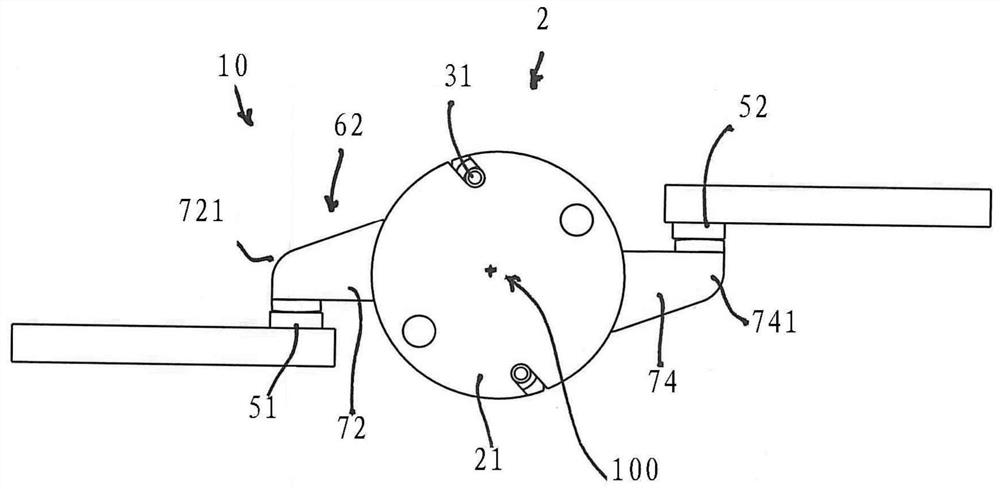

[0047] Referring to the figures, the low voltage contact assembly 1 , 10 of the present invention comprises in its more general definition a rotary support 2 having a body 21 adapted to rotate about a rotation axis 100 .

[0048] exist figure 1 and figure 2 In the single interrupt configuration, the main body 21 supports at least a first pair of movable contacts 11 that can be coupled / disconnected with corresponding first fixed contacts 51 by rotating around the rotation axis 100 open.

[0049] In particular, the first pair of movable contacts 11 generally comprises a first movable contact 61 and a second movable contact 62 , both housed in said rotary support 2 . According to known embodiments, the first movable contact 61 and the second movable contact 62 have corresponding first and second elongated contact bodies 71 and 72, the first elongated contact body 71 And the second elongated contact body 72 has contact ends 711 , 721 protruding from the rotary support 2 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com