Quick-open adjustable air-tight door

A technology of sealing doors and sealing strips, which is applied in the field of cement equipment, can solve problems affecting the normal production and processing of cement equipment, uneven pressing force between door panels and door frames, poor structural reliability, etc., and achieve a stable and reliable overall assembly structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

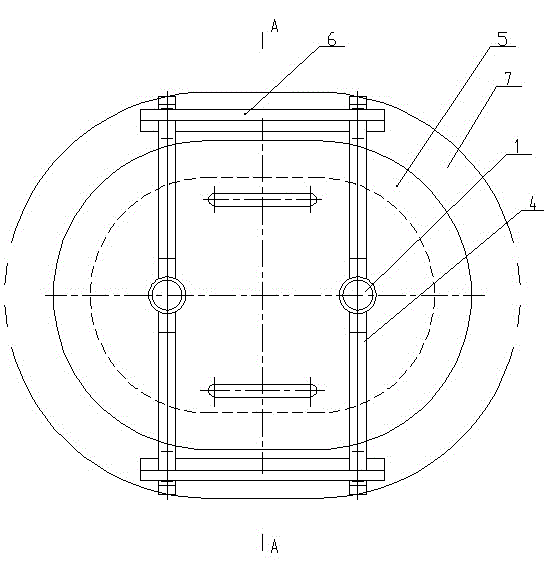

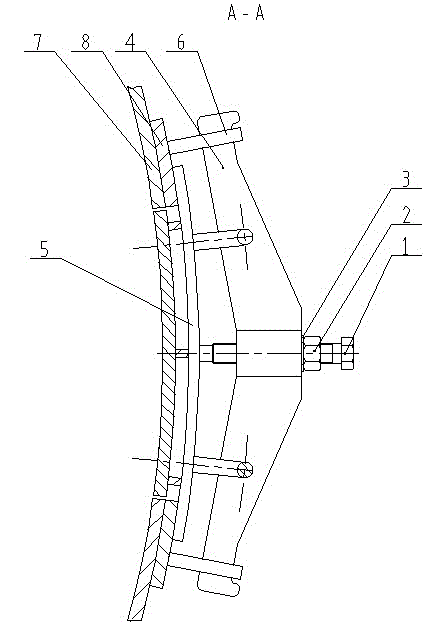

[0012] Such as figure 1 , 2 As shown, it is a quick-open adjustable airtight door, including a bottom frame 7 and a door cover 5, a sealing strip 8 is set between the bottom frame 7 and the door cover 5, two ears 6 are connected on the bottom frame 7, and the door cover 5 Two crossbeams 4 are arranged on the outside, and the two ends of each crossbeam 4 are respectively inserted in the corresponding ears 6, and the middle part of each crossbeam 4 is threaded to connect the top wire 1 respectively, and the inner end of each top wire 1 is connected with the door cover respectively. 5 contact settings. Each jacking screw 1 is threadedly connected with a nut 2 , and each nut 2 is respectively arranged on the outside of the beam 4 , and a gasket 3 is respectively arranged between each nut 2 and the corresponding beam 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com