Gas sensor, gas detector, and self-testing and self-correcting method therefor

A gas sensor and gas detector technology, which is used in instruments, measuring devices, scientific instruments, etc., can solve the problems that the service life is easily affected by environmental temperature and humidity, electrolyte leakage, etc., so as to achieve the correction and improvement of baseline drift and sensitivity. The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with embodiment the content of the present invention is described in detail, those skilled in the art can understand that, the present invention is not limited to following specific embodiment, also can produce multiple different concrete implementations within the scope of the technical solution of the present invention Way.

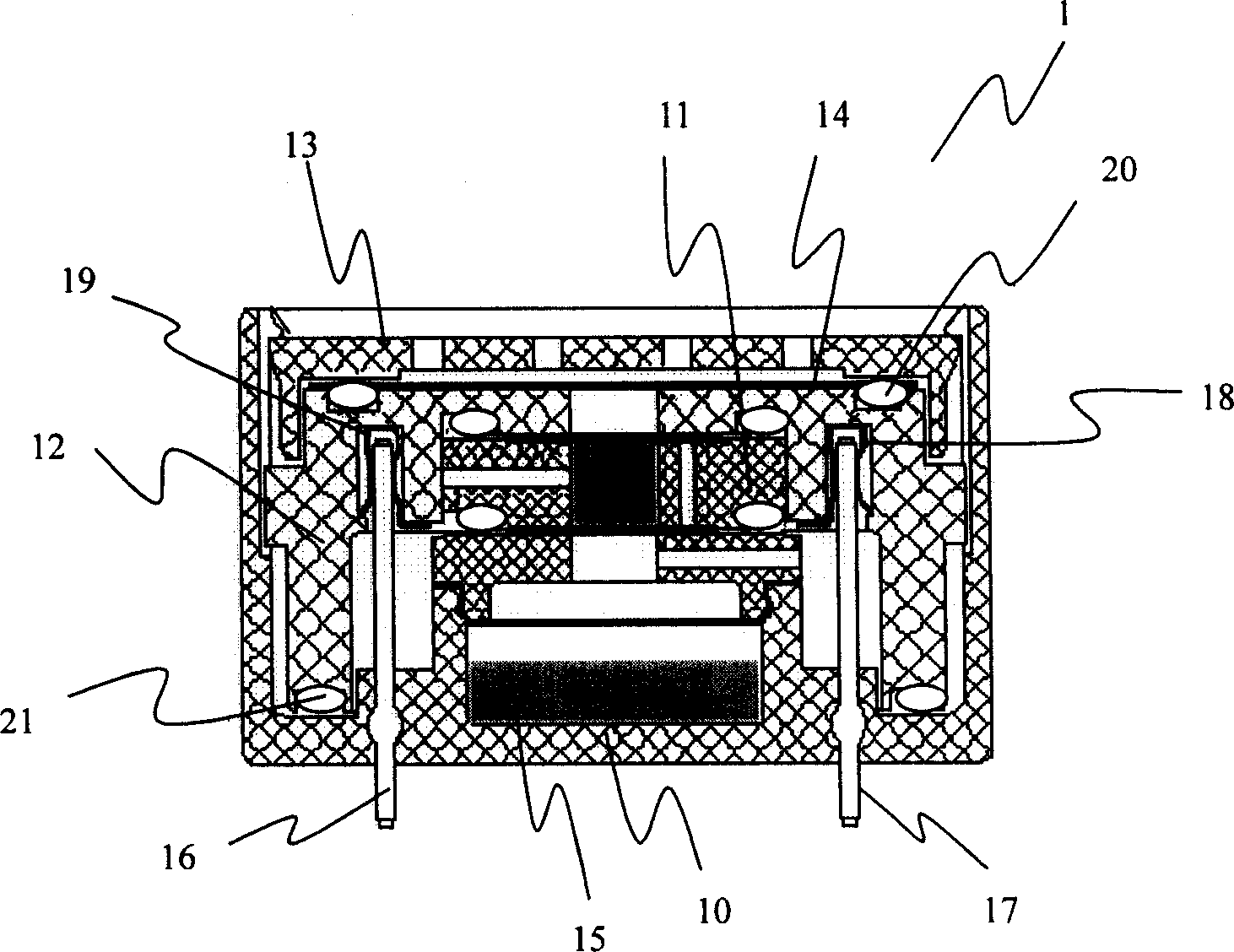

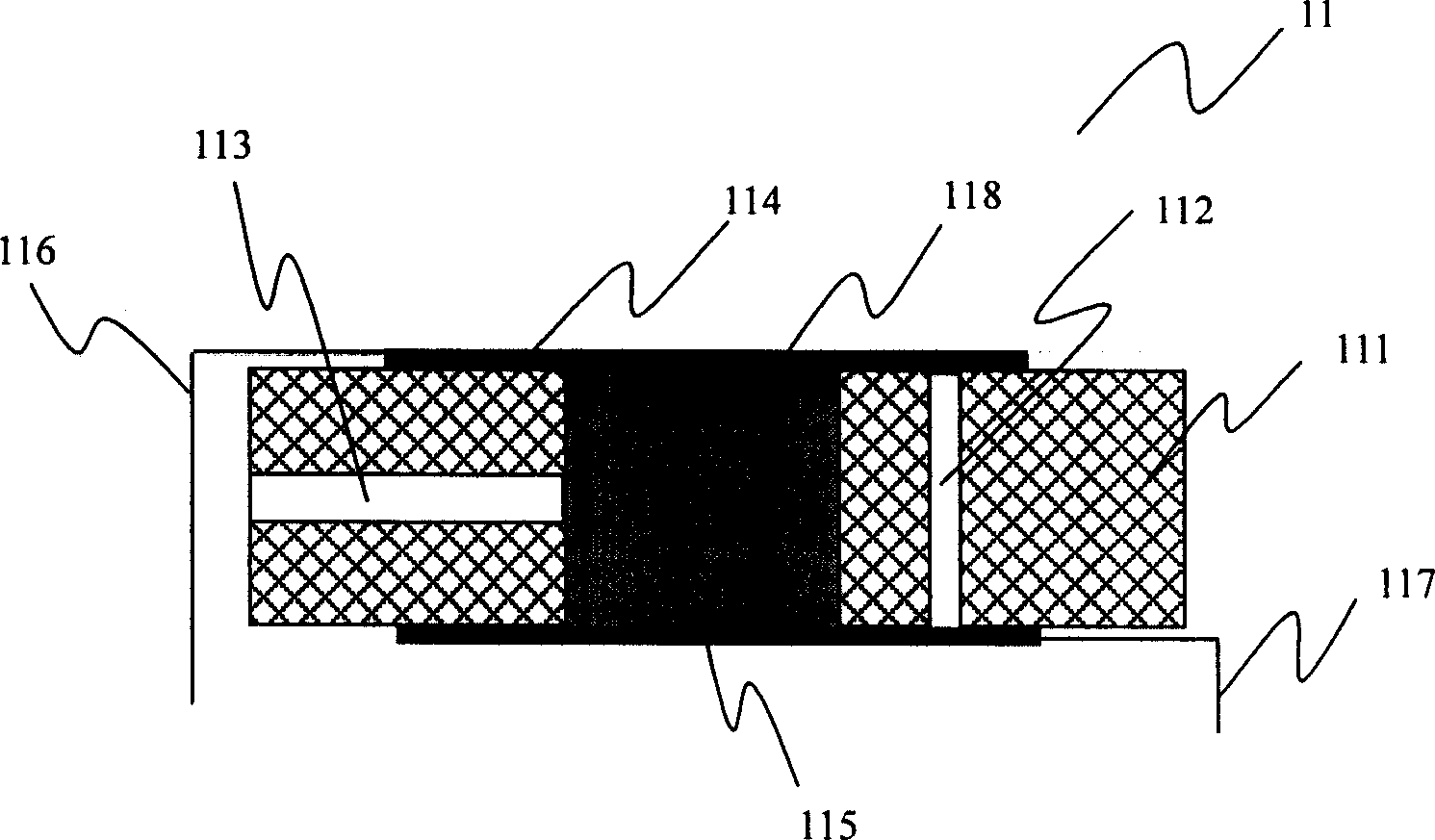

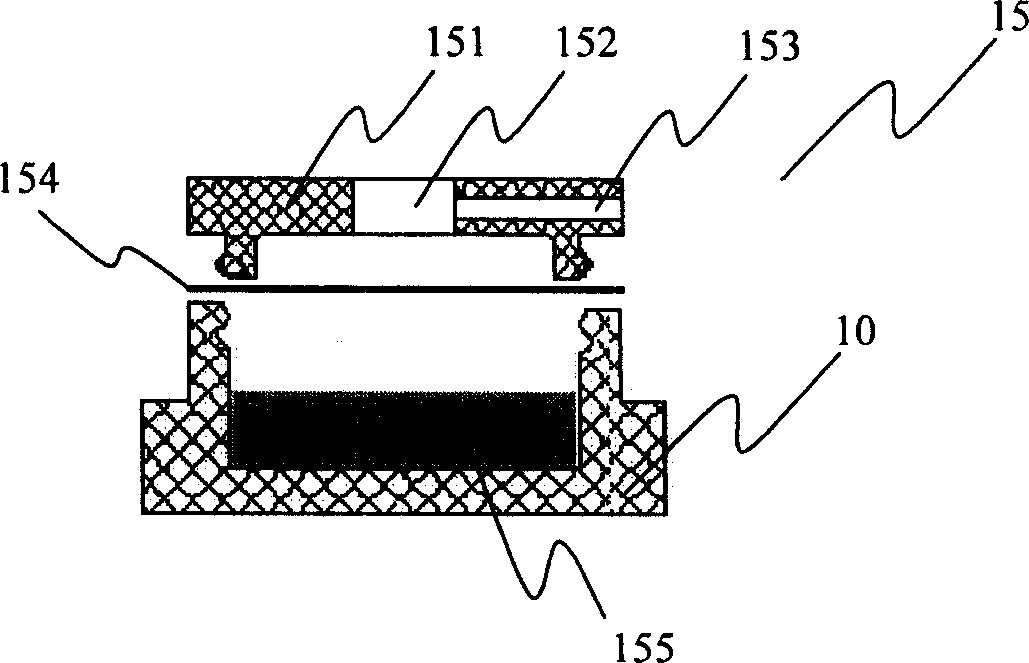

[0042] figure 1 It is a schematic diagram of the structure of the fuel cell gas sensor in the preferred embodiment of the present invention. In the fuel cell gas sensor 1, the battery core assembly 11 (for its structure, see figure 2 ) is placed in the cavity of the battery holder 12, wherein the working electrode 114 faces the central hole of the battery holder 12, so that the target gas coming from the central hole can directly reach the working electrode 114. The counter electrode 115 on the battery core assembly 11 faces the liquid storage cup assembly 15 (for details of its structure, see image 3 ) on the reservoir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com