Electrochemical gas sensor

A gas sensor, electrochemical technology, applied in the direction of material electrochemical variables, scientific instruments, instruments, etc., can solve the problems of low humidity sensitivity, high cost, complex structure of breath analyzer, etc., to achieve low humidity sensitivity, reduce Instrument cost, the effect of solving the broken electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0038] This embodiment describes the case where the air flow direction in the sensor air chamber (7) is parallel to the diffuser port (8) (as shown in the appendix). Figure 5 ) to maximize the effective area of the diffusion port (8). The diffuser port (8) of the sensor is a circle with a diameter of 2.4cm and an area of 4.5cm 2 , the cross-section of the inlet and outlet of the sensor air chamber (7) is a circle with a diameter of 0.5cm, the length of the sensor air chamber (7) is 8.5cm, the width of the sensor air chamber (7) is 2.5cm, and the height of the sensor air chamber (7) is 0.6cm. When the flow rate of the air inlet of the sensor gas chamber (7) is 10mL / s, the simulation effect from the gas diffusion (attached Image 6 ), the area utilization rate of the diffusion port (8) is over 80%, and the effective diffusion area of the diffusion port (8) is greater than 3.6 cm 2 .

specific Embodiment 2

[0039] This embodiment describes the case where the airflow direction in the sensor air chamber (7) is perpendicular to the diffuser port (8) (as shown in the appendix). Figure 7 ) to maximize the effective area of the diffusion port (8). The diffuser port (8) of the sensor is a circle with a diameter of 3 cm and an area of 7.1 cm 2 , the cross section of the inlet and outlet of the sensor air chamber (7) is a circle with a diameter of 1 cm, the length of the sensor air chamber (7) is 3.5 cm, the width of the sensor air chamber (7) is 3.5 cm, and the height of the sensor air chamber (7) is 0.8cm. When the flow rate of the air inlet of the sensor air chamber (7) is 10mL / s, the gas simulation results show that the area utilization rate of the diffusion port (8) is over 85%, and the effective diffusion area of the diffusion port (8) is greater than 6.0cm 2 .

specific Embodiment 3

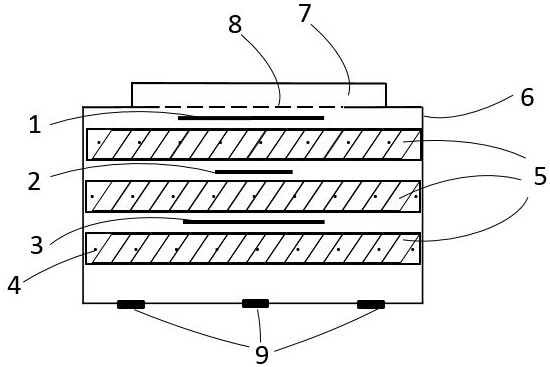

[0040] This example describes an electrochemical H 2 Sensor structure and performance. The sensor structure of this embodiment is as attached figure 1 As shown, the reference electrode (2) and the auxiliary electrode (3) can be arranged longitudinally, and its shape is preferably consistent with the shape of the sensing electrode (1), and its area is preferably not larger than the area of the sensing electrode (1) . The structure of the sensor gas chamber ( 7 ) and the diffusion port ( 8 ) of this embodiment are the same as those of the specific embodiment 1. The shape of the sensing electrode (1), the reference electrode (2), and the auxiliary electrode (3) of the sensor are all rectangles, and their materials are all platinum / graphene. The reference electrode (2) and the auxiliary electrode (3) are respectively Membrane material (5) is arranged above and below the sensor housing (6), a diffusion port (8) and a signal connector (9) are arranged on the sensor housing (6)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com