A kind of high molecular weight pullulan polysaccharide additive and its application in capsule preparation

A technology of pullulan polysaccharide and high molecular weight, which is applied in the field of capsule preparations, and can solve the problems of weak gelling ability of starch solution, rapid molding, and reduced storage stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

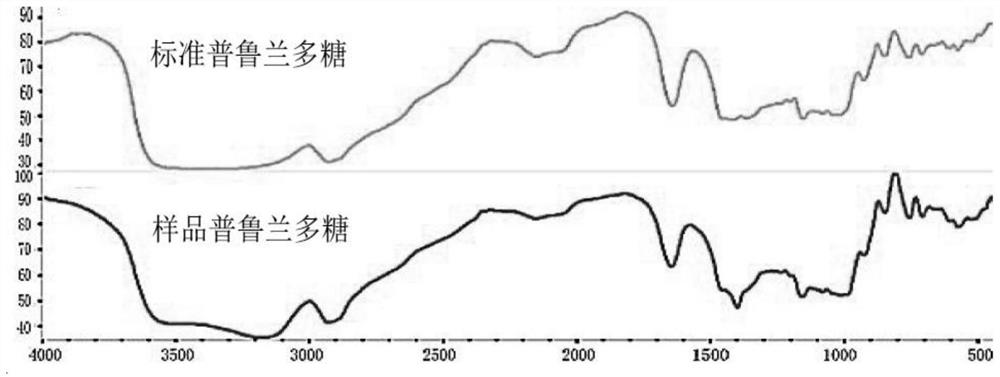

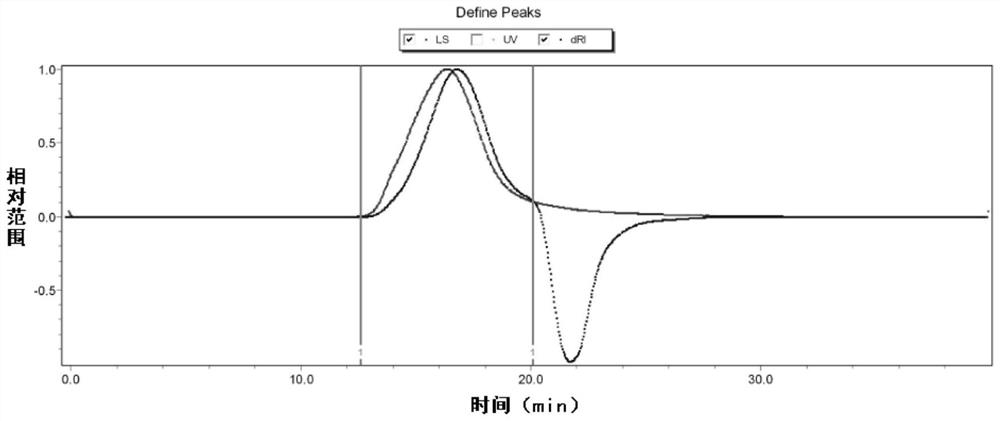

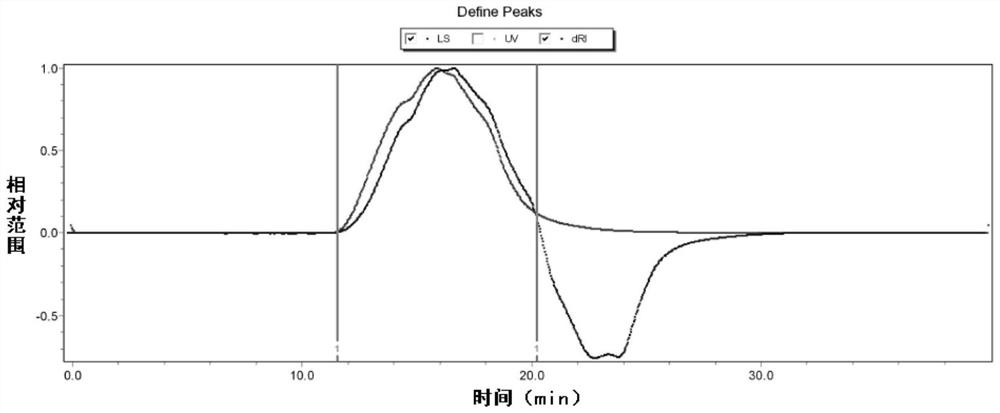

[0062] Example 1 Separation and Purification of High Molecular Weight Pullulan

[0063] The instruments and equipment involved in the embodiment 1 of table 1

[0064] equipment name model supplier high power electric mixer SHF-DY Ningbo Xinyi Biotechnology Co., Ltd. Digital display constant temperature water bath XMDT-204 Changzhou Zhiborui Instrument Manufacturing Co., Ltd. electronic analytical balance ME104E / 02 Mettler-Toledo Instruments Ltd. Electric constant temperature blast drying oven DHG-9030A Shanghai Qixin Scientific Instrument Co., Ltd. Kjeldahl nitrogen analyzer SKD-1000 Shanghai Peiou Desktop High Speed Refrigerated Centrifuge TGL-20M Xiangyi Group Electronic Display pH Meter STARTER3100 Changzhou Danrui Experimental Instrument Co., Ltd. muffle furnace TOL-1400A Tianyuan Instrument Co., Ltd. Atomic Absorption UV Spectrophotometer GGX-100 Haiguang Instrument Co., Ltd. ...

Embodiment 2

[0103] Embodiment 2 pullulan film preparation

[0104] 1, adopt the PLA pullulan polysaccharide (referred to as P4) that embodiment 1 makes, utilize cast method to prepare pullulan polysaccharide film; And, set 3 groups of low molecular weight pullulan polysaccharide comparison groups, wherein, P1 is Mw =88290 pullulan (food grade, purchased from Zibo United Technology Chemical Co., Ltd.), P2 is the pullulan of Mw=140800 (food grade, purchased from Zhongke Hongji Biotechnology Co., Ltd.), P3 is Mw =174200 pullulan (food grade, purchased from Zhongke Hongji Biotechnology Co., Ltd.).

[0105] Weigh 2.7 g of P1 pullulan, dissolve it in 120 mL of distilled water, and prepare a 30 g / L pullulan solution. 120mL pullulan solution is equally divided into four parts, placed in four small beakers, and 0%, 10%, 20%, and 30% of the pullulan quality are added to the pullulan solution in the beakers. Glycerin was stirred magnetically at 800rpm, and after mixing, the air bubbles in the solu...

Embodiment 3

[0122] Embodiment 3 capsule preparation

[0123] (1) Prepare the glue solution: according to the proportioning requirements, the PLA pullulan polysaccharide (P4) prepared in Example 1 of 110g / L, 0.2g / L gellan gum (food grade, purchased from Shandong Zhongkai Food Ingredients Co., Ltd. ) and 0.8g / L potassium citrate and glycerol (glycerol addition is 10% of the P4 pullulan quality), pour in the 150mL beaker that fills 100mL distilled water, prepare 100mL mixed glue, then put into 80 ℃ water bath In the pot, stir continuously until the polysaccharide is completely dissolved. The dissolved glue was degassed, kept at 45°C for 30 minutes, and set aside.

[0124] (2) Glue dipping: at 15°C, slowly insert the 0# capsule mold vertically downward into the prepared glue solution, pull out the mold at a constant speed after standing for 5 seconds, and fix the pulled out capsule mold on the support placed in a drying oven at 50°C for 30 min.

[0125] (3) Shelling and cutting: the dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com