Catalyst for completely removing formaldehyde in indoor air at room temperature

A room temperature, formaldehyde technology, applied in the preparation of mesoporous materials, the above-mentioned mesoporous materials, high-efficiency humidity-resistant room temperature removal of formaldehyde in the field of catalysis, can solve the problem of expensive catalysts, etc., to achieve excellent economy, high stability and long-term performance , high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

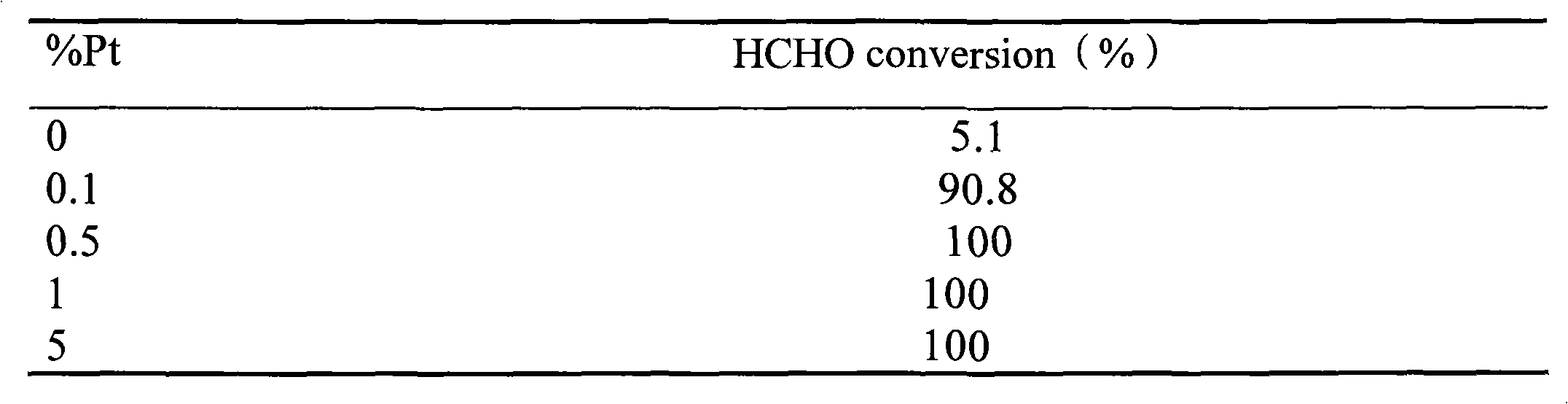

Examples

Embodiment 1

[0031] Preparation of Mesoporous CeO2 Nanomaterials

[0032] Add 10g of P123 containing 0.01mol Ce(NO 3 ) 4 Add 40ml of trioctylamine to 250ml of aqueous solution under constant stirring to obtain a sol, then seal it and crystallize at 50°C for 24h, then transfer the sol to a kettle with a polytetrafluoroethylene liner, Hydrothermal at 100°C for 24h, the resulting product was repeatedly washed with deionized water and ethanol, then placed in an electric vacuum oven and dried in vacuum at 100°C for 24h; finally put into a muffle furnace and calcined at 500°C for 6h to remove the template , the obtained powder is the mesoporous cerium oxide sample. Small angle XRD and HRTEM analysis prove CeO 2 The pore size is 2nm.

[0033] The preparation of the mesoporous cerium dioxide nanomaterial loaded on the honeycomb ceramic carrier involves weighing a certain amount of doped mesoporous ceria nanomaterial, and adding a certain proportion of deionized water and binder. According to ...

Embodiment 2

[0039] Preparation of Mesoporous CeO2 Nanomaterials. Add 10g of P123 containing 0.01mol Ce(NO 3 ) 4 Add 40ml of trioctylamine to 250ml of aqueous solution under constant stirring to obtain a sol, then seal it and crystallize at 50°C for 24h, then transfer the sol to a kettle with a polytetrafluoroethylene liner, Hydrothermal at 100°C for 24h, the obtained product was repeatedly washed with deionized water and ethanol, then placed in a vacuum oven and dried in vacuum at 100°C for 24h; finally put into a muffle furnace and calcined at 500°C for 6h to remove the template. The obtained powder is the mesoporous cerium oxide sample. Small angle XRD and HRTEM analysis prove CeO 2 The pore size is 2nm.

[0040] The preparation of the mesoporous cerium dioxide nanomaterial loaded on the honeycomb ceramic carrier involves weighing a certain amount of doped mesoporous ceria nanomaterial, and adding a certain proportion of deionized water and binder. According to the requirements of ...

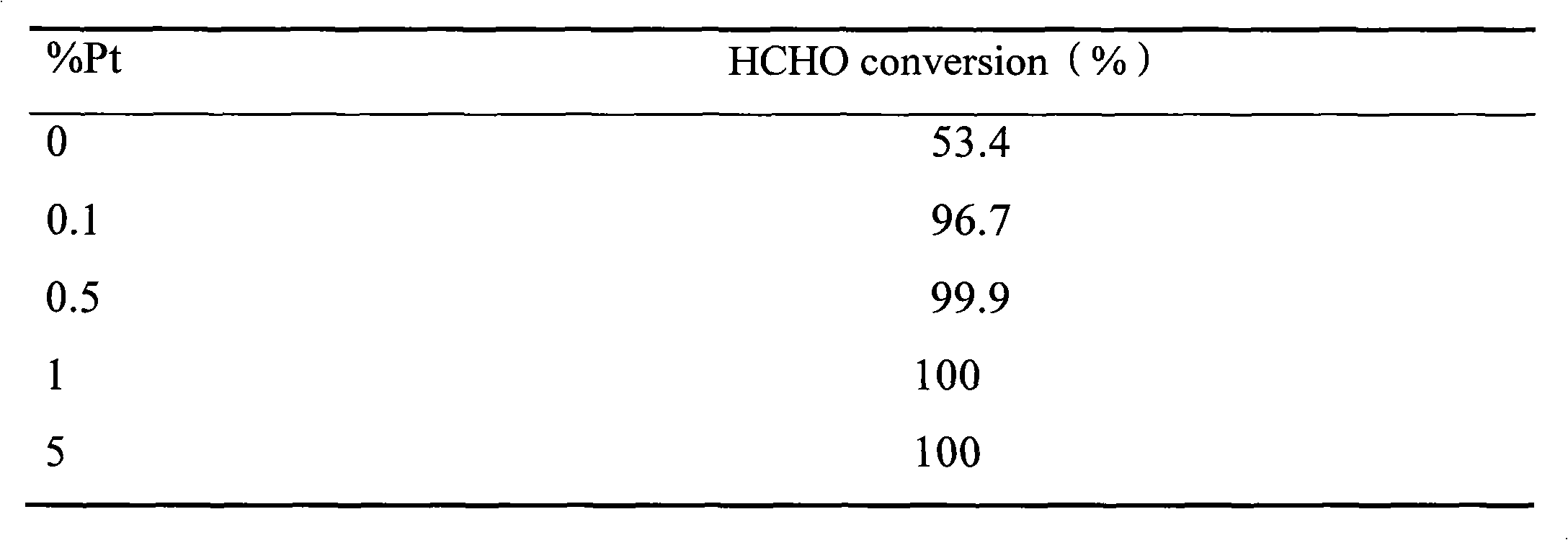

Embodiment 3

[0046] The preparation of the Pt-loaded mesoporous ceria nanomaterial is the same as in Example 2.

[0047] The performance test of the catalyst stability experiment is the same as in Example 1, the continuous test time is 120 days, and the formaldehyde at the entrance is 5 mg / m 3 , the outlet concentration of formaldehyde is 0.001mg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com