Photocatalyst film having light activity visible basal body and method for preparing the same

A photocatalyst and visible light technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of no visible light activity, no red shift of absorbed light, and insignificant red shift of absorbed light, etc. Achieve good self-cleaning and anti-fog effects and high visible light activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

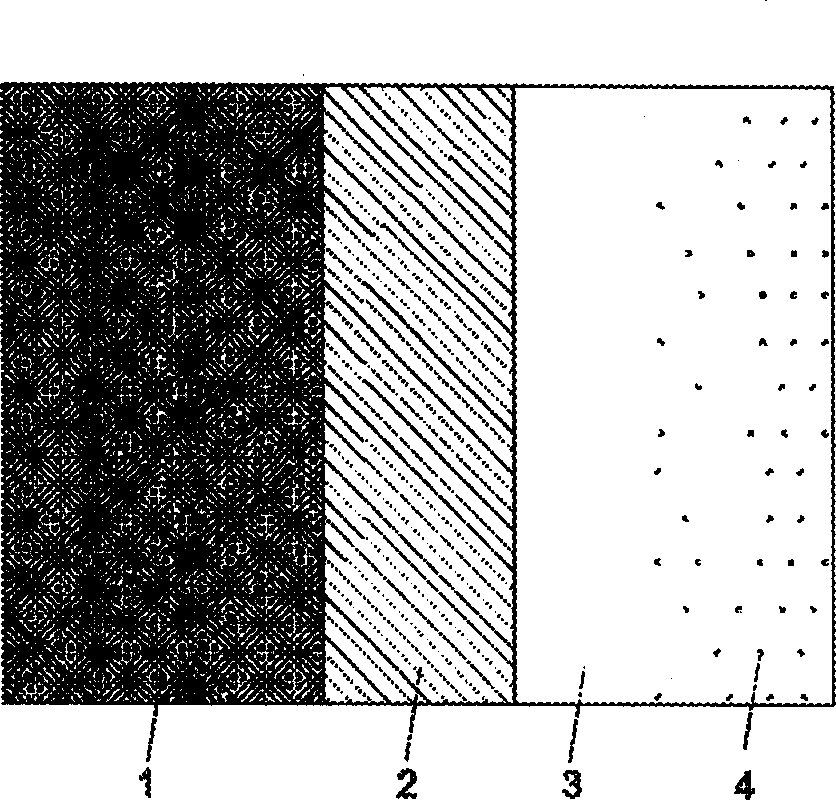

[0025] The visible-light-active photocatalyst film structure on the substrate is as follows: figure 1 shown. In the figure, SiO is deposited on the base glass (1) 2 Thin film layer (2) and semiconductor photocatalyst layer TiO 2 (3), TiO 2 Tungsten oxide (4) was deposited on the surface to realize the doping modification of the photocatalyst by metal ions. (a) SiO on substrate 2 Film preparation

[0026] Preparation of silica sol: take 100ml of absolute ethanol, 104ml of tetraethyl orthosilicate, and 160ml of absolute ethanol in a 500ml Erlenmeyer flask at 900rpm and stir for 1hr, then slowly drop 26ml of HCl (2M) into the above Erlenmeyer flask while stirring evenly After dripping, continue to stir for 1 hr, and stand in the dark for 24 hr to obtain silica sol.

[0027] Ordinary glass pieces (200mm×34mm×2mm) were soaked in acid solution, potassium dichromate lotion solution and distilled water, washed and dried. Dip the pulled glass piece once in silica sol (2mm s -1 ...

Embodiment 2

[0033] WO is sputtered with embodiment 1 step (c) 3 TiO 2 film at N 2 2°C·min under protection -1 Program the temperature to 500°C and keep the temperature constant for 5 hours. (The sample is recorded as H-5hr for later testing).

Embodiment 3

[0034] Example 3 (a) SiO on the substrate 2 Film preparation: same as Example 1. (b) SiO 2 TiO on film 2 Film preparation:

[0035]Preparation of titanium sol: Take 110ml of absolute ethanol, 68ml of tetrabutyl titanate, 16.5ml of diethanolamine, and 100ml of absolute ethanol in a 500ml Erlenmeyer flask at 900rpm and stir for 1hr. 3.6mlH 2 O was slowly added dropwise to the above Erlenmeyer flask, and after the drop, continued to stir for 0.5 hr, and left to stand in the dark for 24 hr to obtain titanium sol. Where molar ratio Ti(OBu) 4 : C 2 h 5 OH:H 2 O:NH(C 2 h 4 Oh) 2 =1:26.5:1:1.

[0036] Will have SiO on the surface 2 The glass sheet of the film was dipped and pulled once in titanium sol (2mm s -1 ), bake in an electric drying oven at 100°C for 10 minutes, and repeat the process from pulling to drying 5 times. (c) WO on substrate film 3 preparation of

[0037] Using the current adjustable magnetron sputtering apparatus, the output power is 1350W (450V×3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com