Carbon nano tube Poisson ratio material

A technology of carbon nanotubes and carbon nanotube films, applied in the field of Poisson's ratio materials, to achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

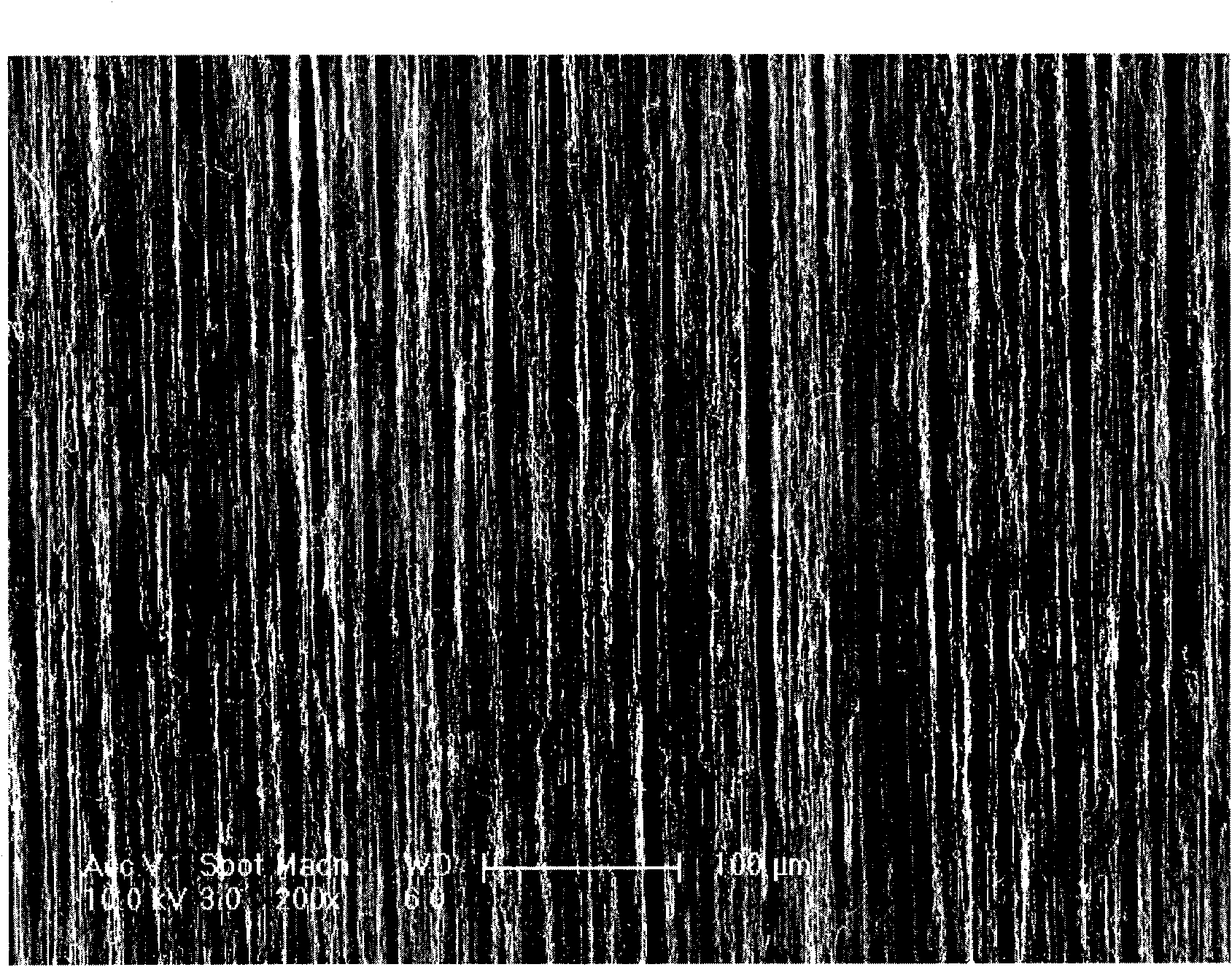

[0032] The carbon nanotube array provided in the embodiment of the present invention is one or more of a single-wall carbon nanotube array, a double-wall carbon nanotube array, and a multi-wall carbon nanotube array. In this embodiment, the preparation method of the carbon nanotube array adopts the chemical vapor deposition method, and its specific steps include: (a) providing a flat substrate, which can be a P-type or N-type silicon substrate, or an oxide layer formed thereon silicon substrate, the present embodiment preferably adopts a 4-inch silicon substrate; (b) uniformly form a catalyst layer on the surface of the substrate, and the catalyst layer material can be selected from iron (Fe), cobalt (Co), nickel (Ni) or One of alloys in any combination; (c) annealing the substrate formed with the catalyst layer in air at 700-900°C for about 30 minutes to 90 minutes; (d) placing the treated substrate in a reaction furnace, Heating to 500-740° C. under a protective gas environm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com