Carbon fiber grounding grid anti-corrosive paint and preparation and application methods thereof

A technology of anti-corrosion coatings and application methods, applied in the directions of anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of not many specific functions, the influence of the conductive properties of conductive coatings, and the adhesion to be improved, so as to achieve uniform surface composition. , avoid bubbles or defects, improve the effect of anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

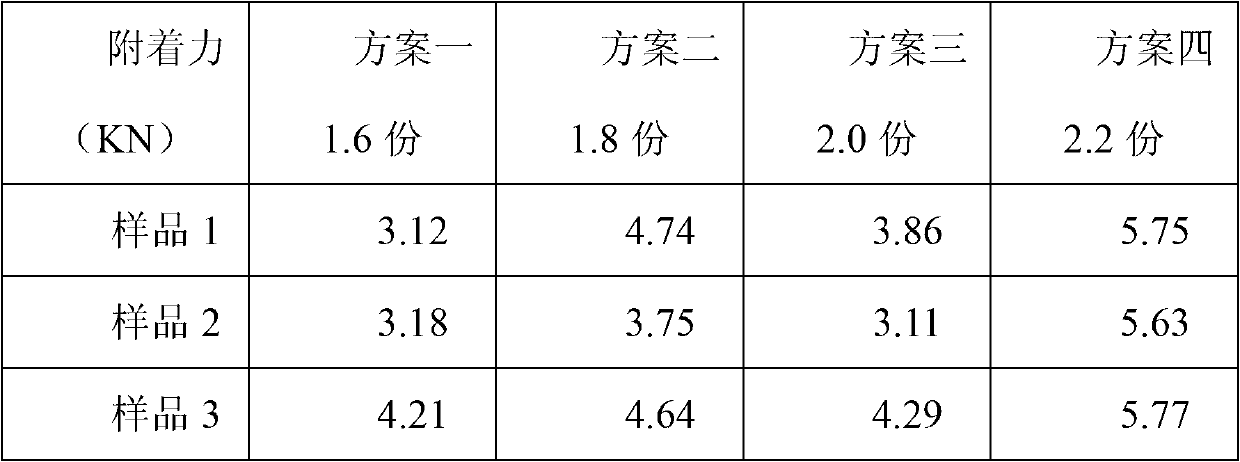

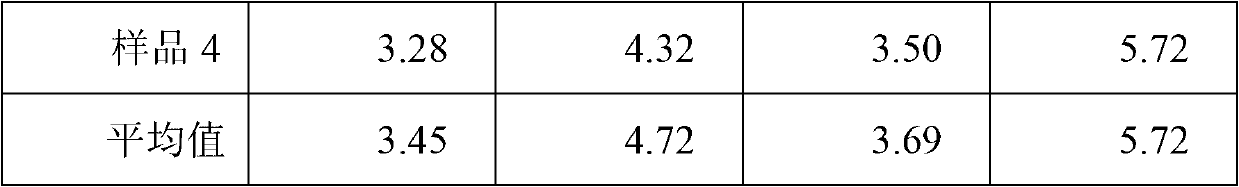

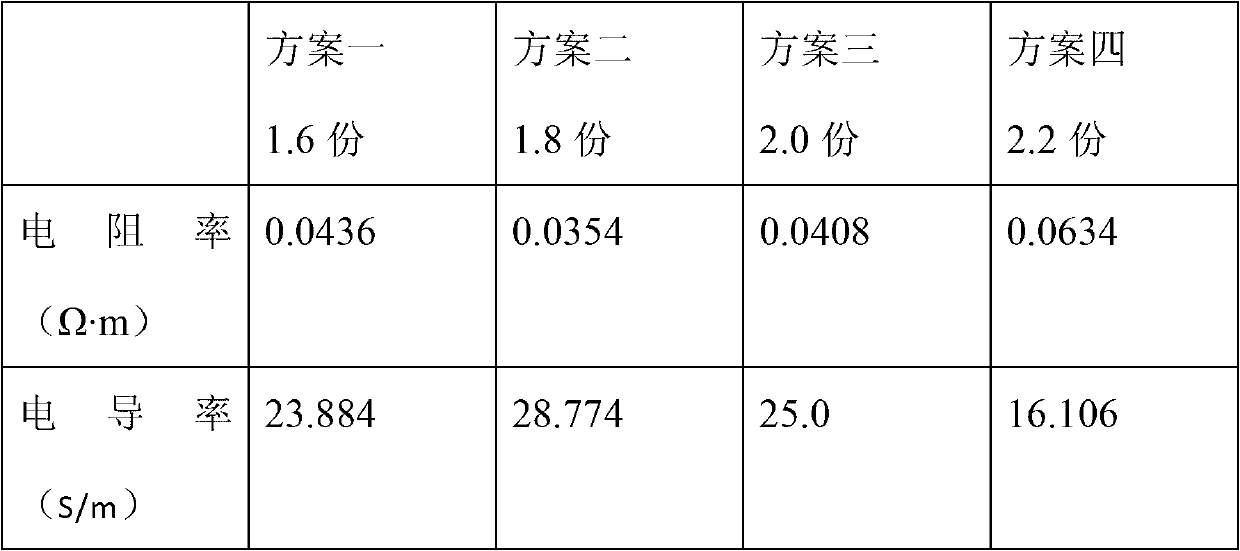

[0034] 1) Weigh 30 parts of acrylic resin (manufacturer: Holland DSM Zeneca, model: B-725), add 50 parts of dissolving agent (xylene) to the acrylic resin and stir for 10-30 minutes until the acrylic resin is fully dissolved until transparent After mixing, add 0.5 parts of silane coupling agent (KH-550), stir evenly, then add 1.8 parts of epoxy resin, and then stir evenly to obtain a transparent solution; 2) weigh 25 parts of carbon fiber and 5 parts of carbon black Evenly put into the solution to obtain a mixed solution, and then stir for more than 20 minutes so that the components in the mixed solution are mixed evenly, the mixed solution is viscous, and there are no visible particles to obtain a sol; 3) Add 2 to the sol 1 part of diluent (cyclohexene), stir well, then add 0.2 part of curing agent (TDI), then stir well, and finally add 0.1 part of thickener (Xi'an Aoke Chemical Raw Materials Company, hydroxypropyl methylcellulose) and Stir well.

[0035] After the coating i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com