Continuous long-fiber reinforced-type composite material 3D printer and printing method thereof

A reinforced composite material and 3D printer technology, applied in the field of continuous long fiber reinforced composite 3D printers, can solve the problem of undiscovered continuous long fiber reinforced composite 3D printers, unsuitable for batch manufacturing of long fiber reinforced parts, rare fiber reinforced composite materials Parts and other issues, to achieve the effect of reducing process complexity, rapid manufacturing, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

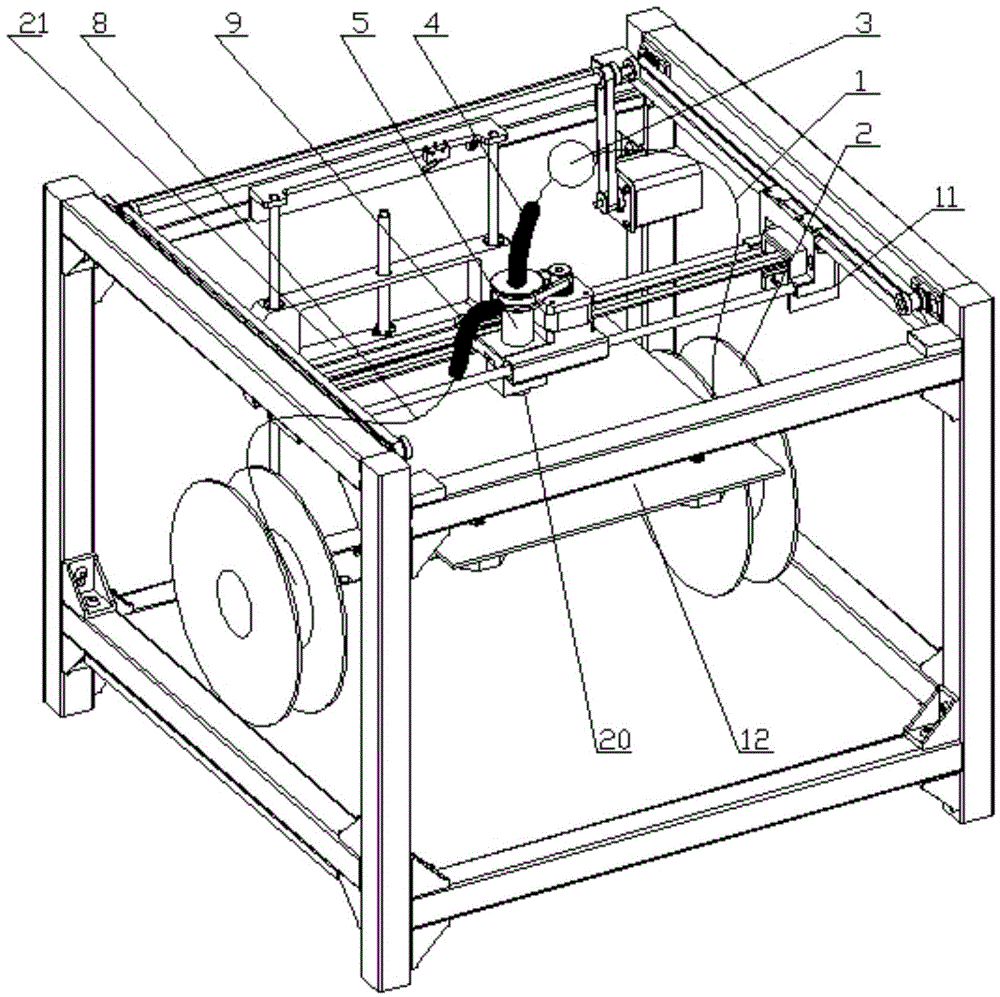

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] refer to figure 1 , a continuous long fiber reinforced composite material 3D printer, comprising a 3D printing head 5, the 3D printing head 5 is installed on a two-dimensional motion platform 11, a workbench 12 is provided below the 3D printing head 5, the workbench 12 and a lifting device 21 connection, the workbench 12 places reinforcement fiber 1 and plastic wire 8 tray 2 on the left and right, reinforcement fiber 1 is fed into the 3D printing head 5 through the tensioning device 3 and fiber guide tube 4, and the plastic wire 8 is guided by the plastic wire The tube 9 is also sent into the 3D printing head 5;

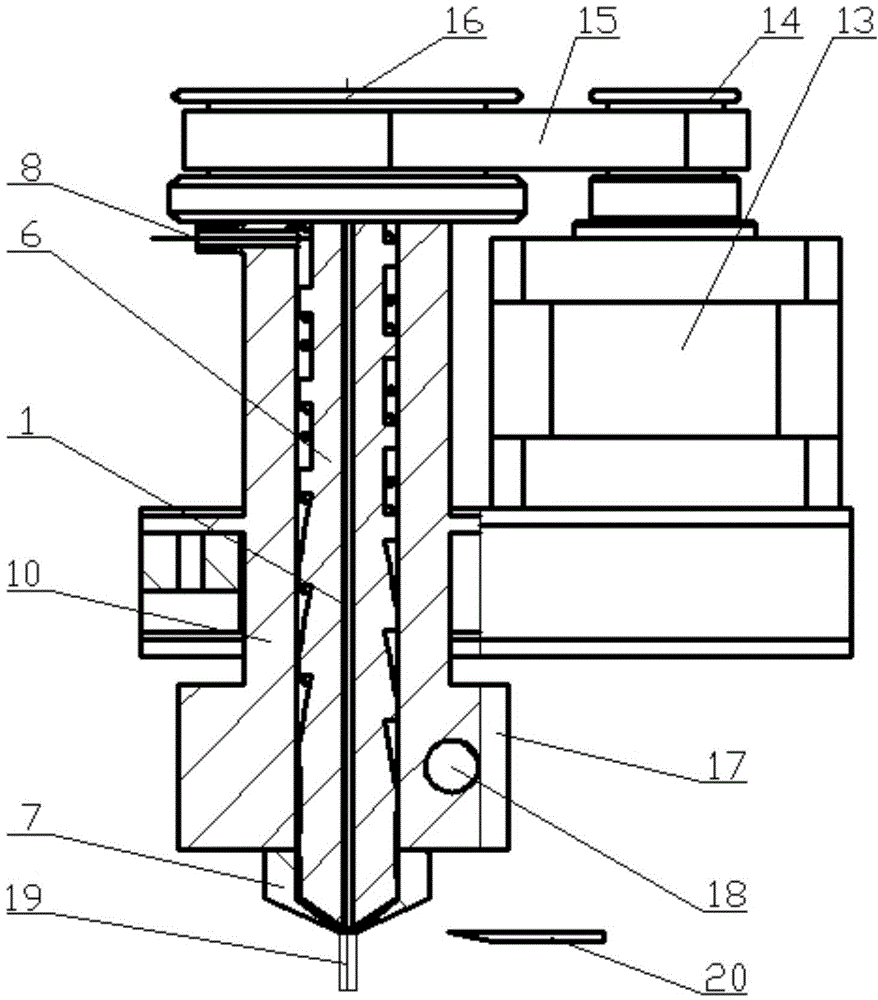

[0021] refer to figure 2 , the 3D printing head 5 includes a printing head screw 6, the outside of the printing head screw 6 is connected to the printing head screw shell 10, the root of the printing head screw 6 is connected to the large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com