Method for preparing aramid nanofibers based on deprotonation of Kevlar and nanofiber prepared thereby

A technology of aramid fibers and nanofibers, applied in fiber types, fiber processing, textiles and papermaking, etc., can solve the limitations of ANF functionalization, diversified large-scale preparation and industrial production, not higher than 2.5% by weight, dispersion liquid Low concentration and other problems, to achieve the effect of accelerating the nanometerization rate, increasing the concentration, and improving the preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

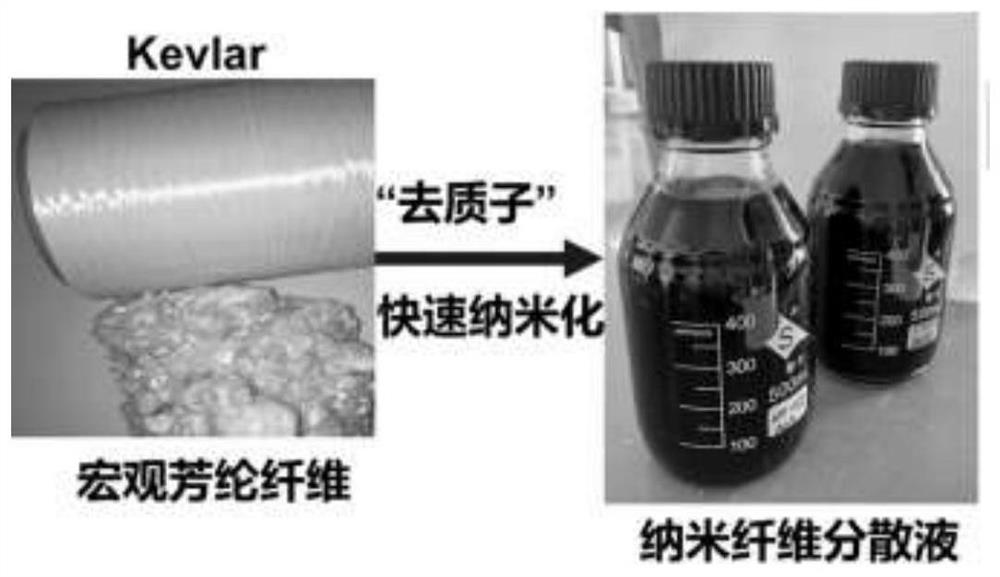

[0041] (1) 6g Kevlar chopped fibers (approximately 12-20 microns in diameter, 6 mm in length, purchased from DuPont), 500ml dimethyl sulfoxide (DMSO), and 1g KOH were added to the reaction vessel. Stirring and pretreatment for 5 minutes at a speed of 4000 rpm in a shearing disperser to obtain a light yellow uniform dispersion of macroscopic aramid fibers.

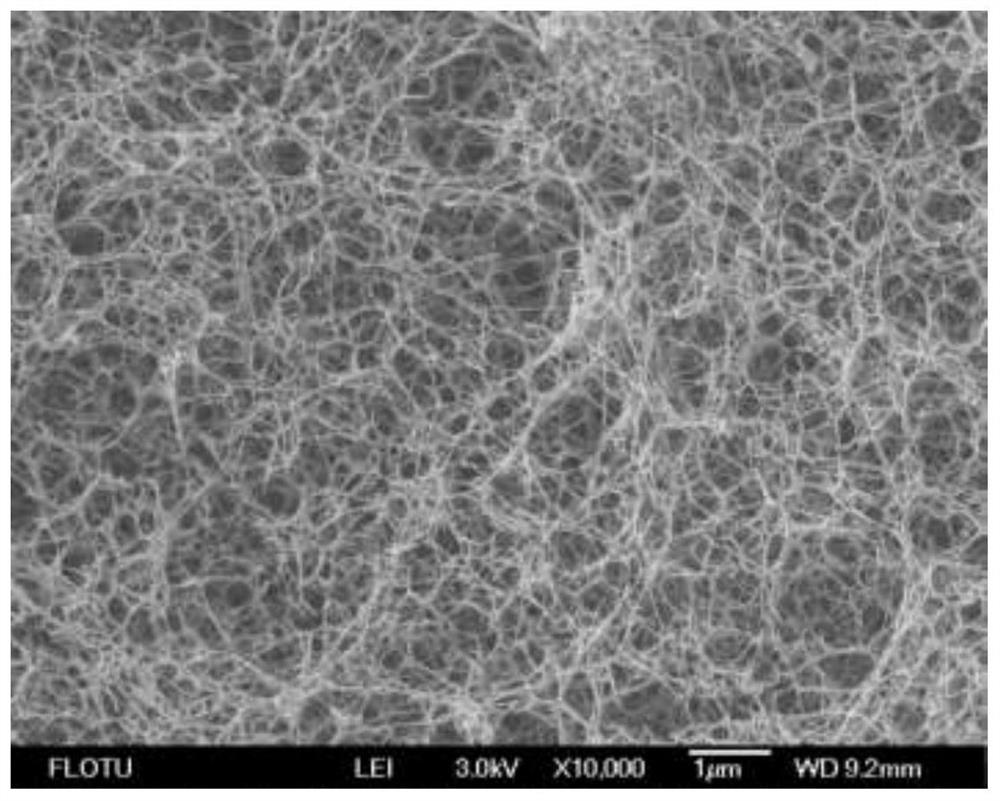

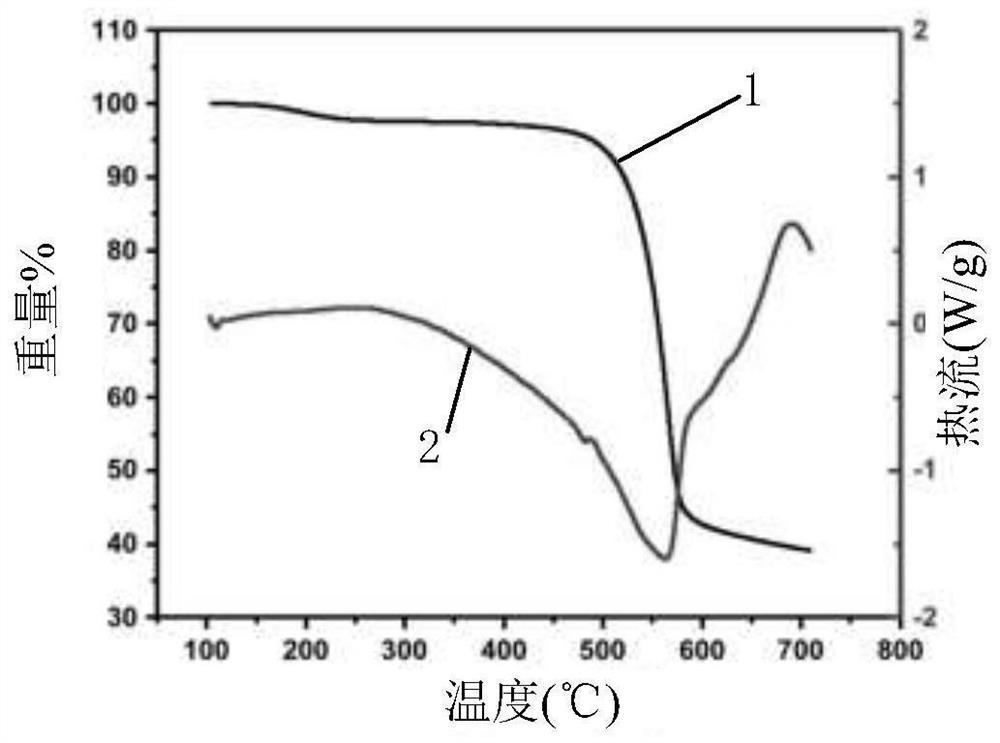

[0042] (2) Add a solution of 18 g of deionized water and 2 g of KOH to the pre-dispersion in step (1) at one time to obtain a mixed solution, adjust the rotation speed and continue stirring for 1 hour to obtain a black-red uniform transparent aramid nanofiber colloidal dispersion. figure 2 The SEM figure of the aramid nanofiber prepared by the present embodiment is shown; image 3 The simultaneous thermal analysis (TG / DSC) diagram of the aramid nanofiber prepared in this embodiment is shown; Table 1 shows the properties of the aramid nanofiber prepared.

Embodiment 2

[0044] (1) 10g of Kevlar chopped fibers used in Example 1, 600ml dimethyl sulfoxide (DMSO), 1g KOH, 1g potassium ethoxide are added in the reaction vessel, under normal temperature environment, high shear disperser 4000rpm rotating speed , stirring and pretreatment for 5 minutes to obtain a light yellow uniform dispersion of macro-aramid fibers.

[0045] (2) Add the solution of 15g deionized water and 3g KOH respectively in the predispersion liquid of step (1), continue stirring reaction 0.5h; Then add 10ml ethanol, 1g potassium ethoxide, adjust the rotating speed to be 3000rpm and continue stirring for 1h , to obtain a black-red uniform transparent aramid nanofiber colloidal dispersion.

Embodiment 3

[0047] (1) 6g of Kevlar chopped fibers used in Example 1, 500ml of N,N-dimethylformamide (DMF), 1g of potassium tert-butoxide are added to the reaction vessel, and under normal temperature environment, the high shear disperser is 4000rpm Stirring and pretreatment for 5 minutes at a rotating speed to obtain a light yellow uniform dispersion of macro-aramid fibers.

[0048] (2) Add 18g of deionized water, 3g of KOH, and 6g of propanol to the pre-dispersion in step (1) at one time, adjust the rotating speed to 3000rpm and continue stirring for 2h to obtain a black-red uniform transparent aramid nanofiber colloidal dispersion .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com