High-performance rubber composite material containing Kevlar nano-fibers and preparation method thereof

A technology of nanofibers and composite materials, applied in the field of rubber composite materials with high mechanical properties and its preparation, which can solve the environmental hazards of organic solvents and other problems, and achieve the effect of improving mechanical properties, high strength, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

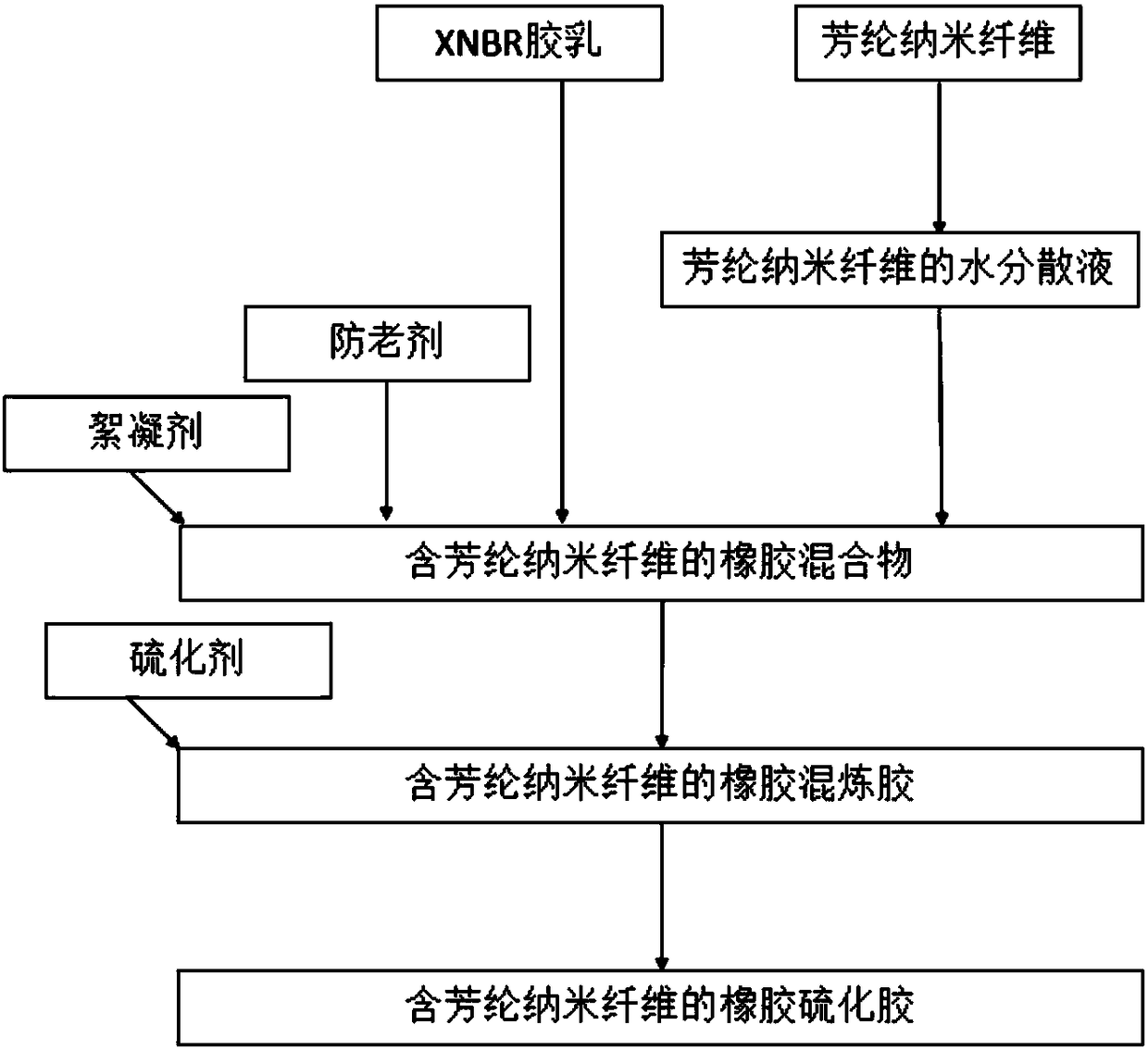

Method used

Image

Examples

Embodiment 1

[0026] Take 1 part of the aqueous dispersion of Kevlar nanofibers, mix it with XNBR rubber latex, add anti-aging agent, stir for 1 hour, adjust the pH value to 2, and add 10wt% NaCl aqueous solution, gel washing, 100°C Drying for 2 hours under the hood to obtain a mixture of XNBR containing Kevlar nanofibers. The dried gel is kneaded on an open mill. The components and their proportions in the rubber compound are: 100 parts of rubber, 0.5 part of anti-aging agent WL, 1 part of vulcanizing agent DCP, and 1 part of Kevlar nanofiber. After the mixed rubber was parked for 24 hours, its positive vulcanization time at 165°C was measured by a vulcanizer, and finally it was vulcanized on a 50t flat vulcanizer to obtain an XNBR composite material containing 1 part of Kevlar nanofibers. The tensile strength of the composite material is 9.82MPa, the elongation at break is 162%, the 100% modulus is 4.88MPa, the 300% modulus is 9.71MPa, and the tear strength is 25.47KN / m.

Embodiment 2

[0028] Take 3 parts of the aqueous dispersion of Kevlar nanofibers, mix it with XNBR latex, add anti-aging agent, stir for 2 hours, adjust the pH value to 2.5, add 12wt% KCl aqueous solution, wash the gel, and dry at 110°C After 2.5h, a mixture of XNBR containing Kevlar nanofibers was obtained. The dried gel is kneaded on an open mill. The components and their proportions in the rubber compound are: 100 parts of rubber, 1 part of anti-aging agent RD, 3 parts of vulcanizing agent DTBP, and 3 parts of Kevlar nanofiber. Other conditions are the same as example 1. The XNBR composite material containing 3 parts of Kevlar nanofibers has a tensile strength of 10.74MPa, an elongation at break of 152%, a 100% modulus of 7.60MPa, a 300% modulus of 10.49MPa, and a tear strength of 28.36KN / m.

Embodiment 3

[0030] Take 5 parts of the aqueous dispersion of Kevlar nanofibers, mix it with XNBR latex, add anti-aging agent, stir for 1.5h, adjust the pH value to 3, and add 4wt% NaCl and 4wt% CaCl 2 The aqueous solution was mixed, the gel was washed, and dried at 100 ° C for 2 h to obtain a mixture of XNBR containing nanofibers. The dried gel is kneaded on an open mill. The components and their proportions in the compound are: 100 parts of rubber, 1 part of anti-aging agent 4010NA, 1 part of anti-aging agent RD, 1 part of vulcanizing agent BIPB, 3 parts of vulcanizing agent DTBP, Kevlar nanofiber : 5 servings. Other conditions are the same as example 1. The tensile strength of the XNBR composite material containing 5 parts of Kevlar nanofibers was 13.12MPa, the elongation at break was 128%, the 100% modulus was 12.17MPa, the 300% modulus was 13.01MPa, and the tear strength was 30.61 KN / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| 100% modulus | aaaaa | aaaaa |

| 300% tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com