Kevlar nanofiber composite forward osmosis membrane, and preparation method and application thereof

A nanofiber, forward osmosis membrane technology, applied in the field of membrane materials, can solve problems such as reducing the strength of aramid fibers, achieve excellent high strength, good solvent resistance, and avoid the use of strong corrosive reagents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of a Kevlar nanofiber composite forward osmosis membrane of this embodiment, the specific operation steps are as follows:

[0035] (1) Put 2g of Kevlar fibers (provided by Dupont) in a round bottom flask, add 2g of auxiliary methanol, 1g of potassium tert-butoxide and 40g of organic solvent dimethyl sulfoxide, mechanically stir and disperse for 2 days at room temperature to form a uniform Stable black-red Kevlar nanofiber dispersion solution;

[0036] (2) Add 20% porogen PEG-600 of Kevlar fiber mass to the solution formed in step (1), mechanically stir for 5 hours to make it form a uniform and stable casting solution, and stand for defoaming for 12 hours for use;

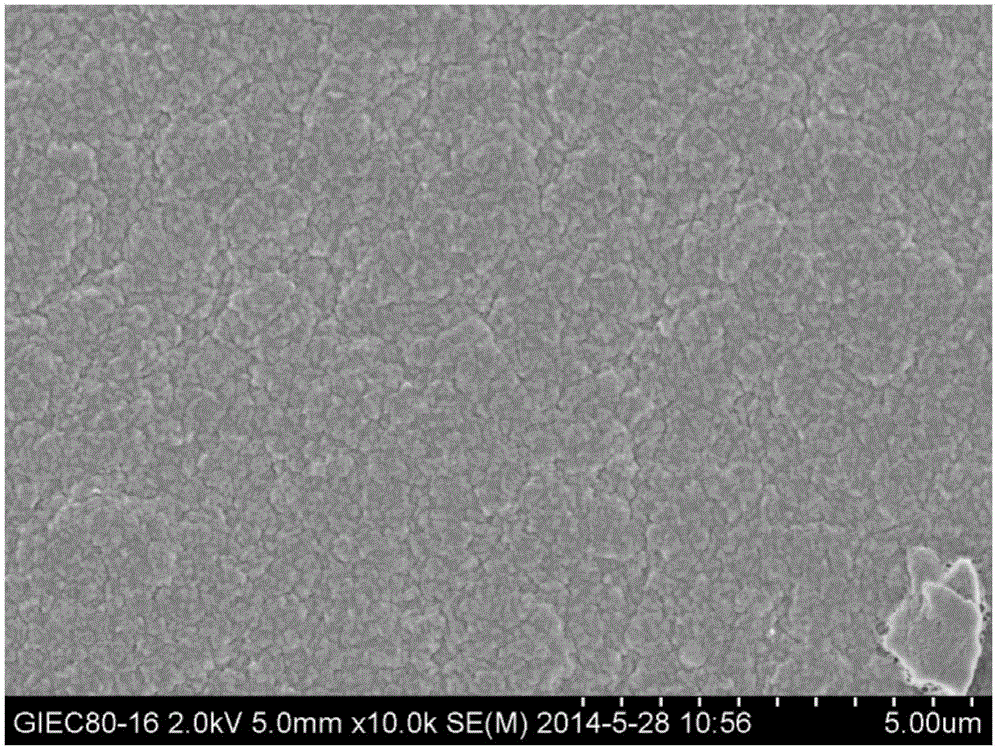

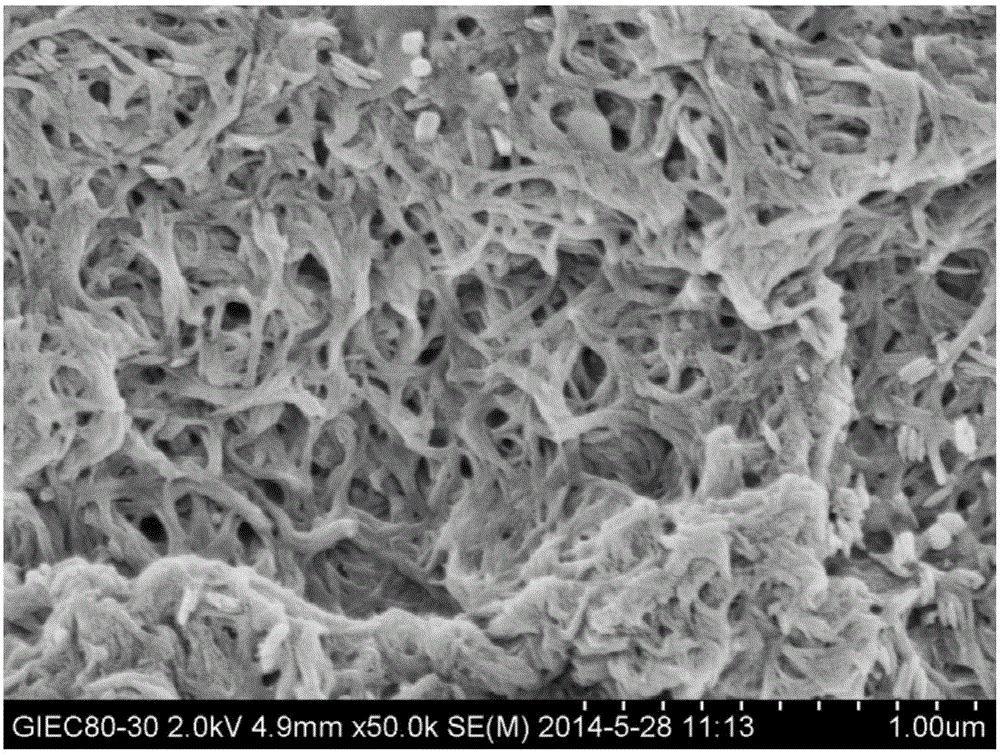

[0037] (3) spreading the film-casting solution of step (2) on a clean glass plate, scraping a film with a thickness of 300um with a film scraper, and immersing it in a distilled hydrogel bath to form a gel film;

[0038] (4) Remove the gel film in step (3) from the glass plate and soak...

Embodiment 2

[0043] The preparation method of a Kevlar nanofiber composite forward osmosis membrane of this embodiment, the specific operation steps are as follows:

[0044] (1) Put 2g of Kevlar fibers (provided by Dupont) in a round bottom flask, add 2g of auxiliary methanol, 1g of potassium tert-butoxide and 40g of organic solvent dimethyl sulfoxide, mechanically stir and disperse for 2 days at room temperature to form a uniform Stable black-red Kevlar nanofiber dispersion solution;

[0045] (2) Add porogen PEG-1000 with 20% Kevlar fiber mass to the solution formed in step (1), mechanically stir for 5 hours to form a uniform and stable casting solution, and stand for defoaming for 12 hours for later use;

[0046] (3) spreading the film-casting solution of step (2) on a clean glass plate, scraping a film with a thickness of 300um with a film scraper, and immersing it in a distilled hydrogel bath to form a gel film;

[0047] (4) Remove the gel film in step (3) from the glass plate and soak ...

Embodiment 3

[0052] The preparation method of a Kevlar nanofiber composite forward osmosis membrane of this embodiment, the specific operation steps are as follows:

[0053] (1) Put 2g of Kevlar fibers (provided by Dupont) in a round bottom flask, add 2g of auxiliary methanol, 1g of potassium tert-butoxide and 40g of organic solvent dimethyl sulfoxide, mechanically stir and disperse for 2 days at room temperature to form a uniform Stable black-red Kevlar nanofiber dispersion solution;

[0054] (2) Add porogen PEG-2000 with 20% Kevlar fiber mass to the solution formed in step (1), mechanically stir for 5 hours to make it form a uniform and stable casting solution, and stand for defoaming for 12 hours for later use;

[0055] (3) spreading the film-casting solution of step (2) on a clean glass plate, scraping a film with a thickness of 300um with a film scraper, and immersing it in a distilled hydrogel bath to form a gel film;

[0056] (4) Remove the gel film in step (3) from the glass plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com