A filling type whipple protective structure based on basalt fiber fabric and its manufacturing method

A technology of basalt fiber and protective structure, applied in the direction of aerospace safety/emergency devices, layered products, etc., can solve problems such as inaccessibility, and achieve the effect of strong engineering application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

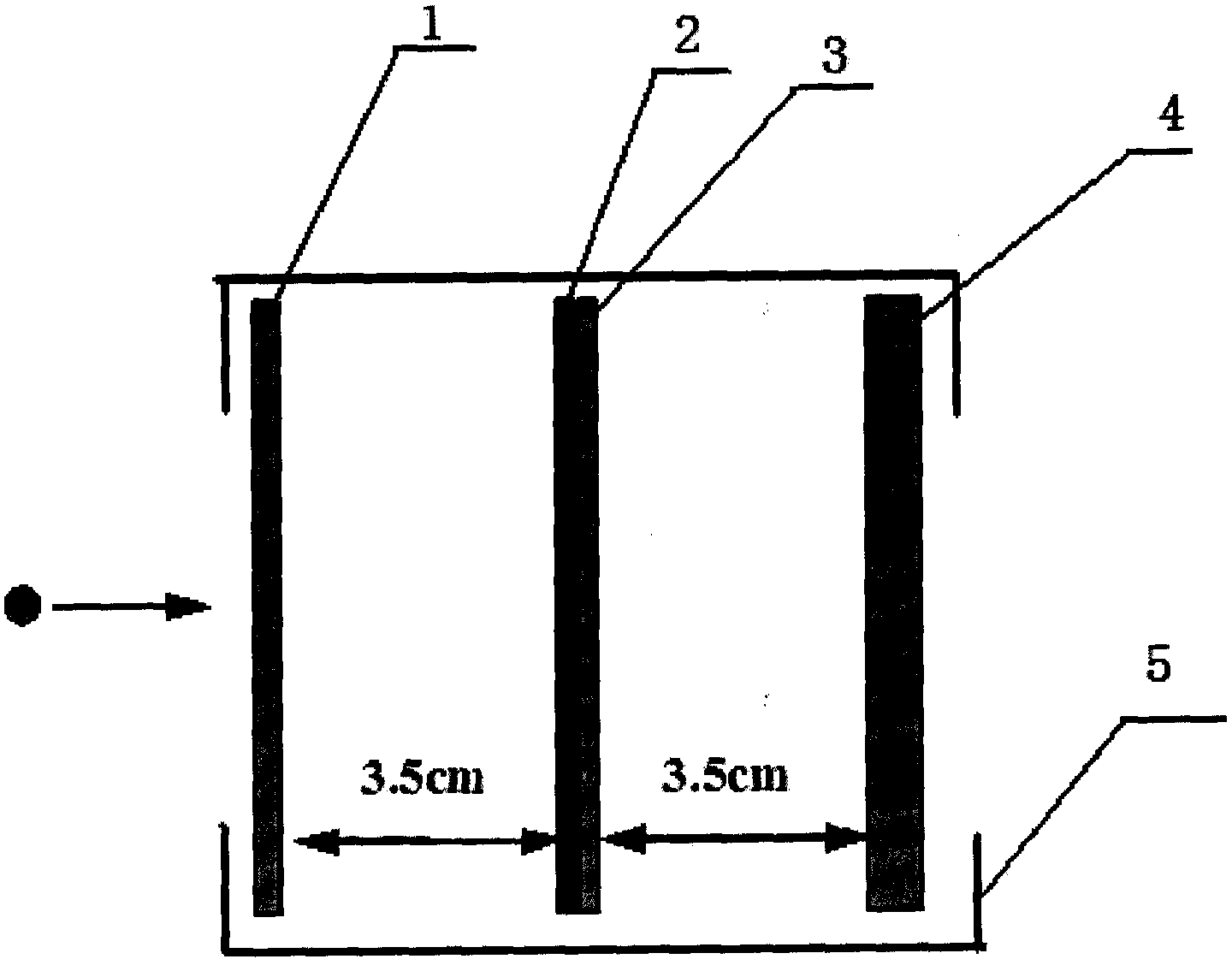

[0022] Such as figure 1 A filled Whipple protective structure based on basalt fiber fabric is shown, the protective structure includes: a buffer screen 1, a filling layer and a back wall 4, the filling layer being located between the buffer screen 1 and the back wall 4;

[0023] The filling layer is divided into two parts: basalt fiber fabric 2 and Kevlar fiber fabric. The basalt fiber fabric 2 and Kevlar fiber fabric 3 are stacked together. The basalt fiber fabric 2 is opposite to the buffer screen 1. The stretch fiber fabric 3 is opposite to the rear wall 4, and the distance between the buffer screen 1 and the filling layer, and between the filling layer and the rear wall 4 is 3.5 cm.

[0024] The basalt fiber fabric 2 and the Kevlar fiber fabric 3 have three layers.

[0025] The thickness of the buffer screen 1 is 1 mm, and the thickness of the rear wall 4 is 2.5 mm.

[0026] Said basalt fiber fabric 2, single-layer fiber density≤2.65g / cm 3 , Fiber tensile modulus ≥70GPa, fiber te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com