Optical cable strengthening core and manufacture method thereof

A fiber optic cable strengthening core and light source technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of fiber breakage and damage, insufficient elasticity of the cable sheath, and low tensile force of the cable body, achieving small size, excellent bending resistance The effect of folding special functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

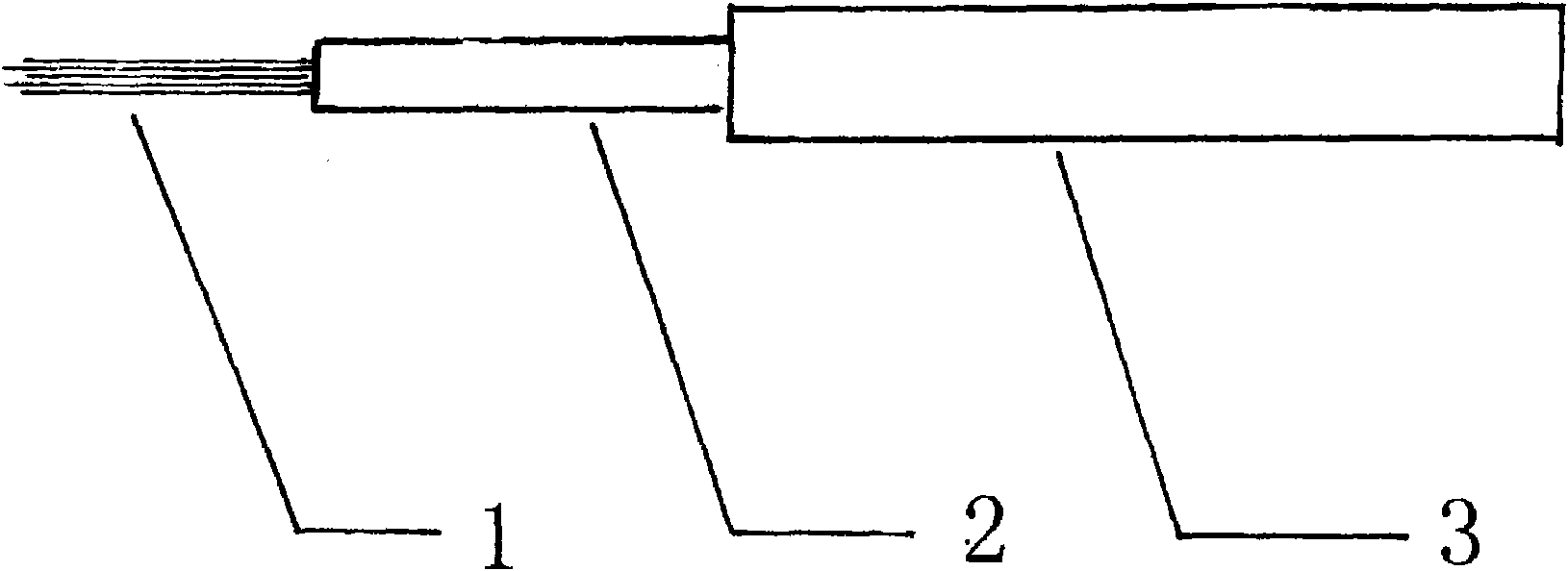

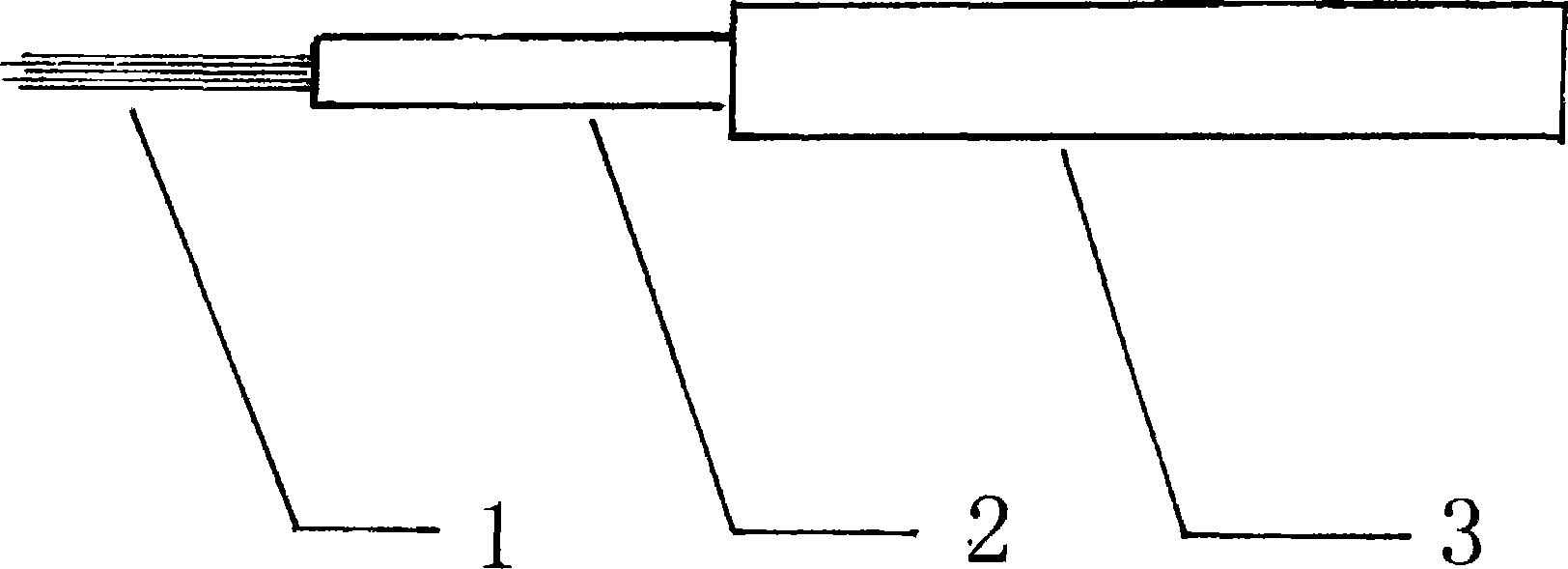

[0023] Epoxy resin UV curing of aramid fiber

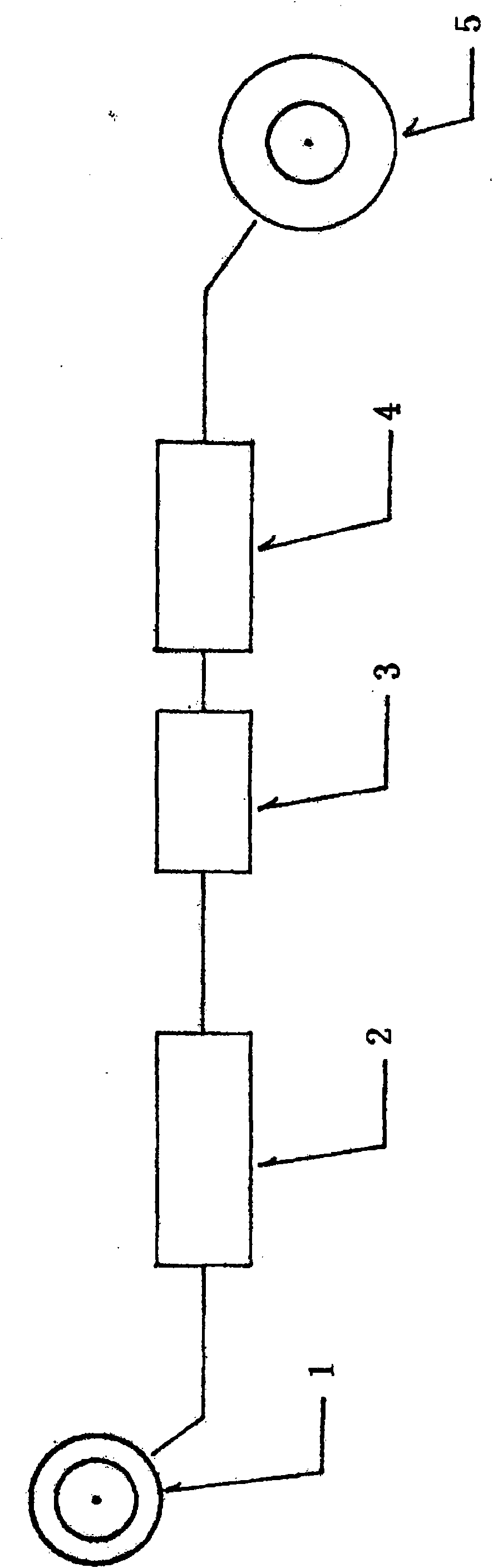

[0024] see figure 1 , the optical cable strengthening core of the present invention is a high-strength anti-folding aramid fiber optical cable strengthening core, which uses aramid fiber tow 1 as a matrix, and the outside is coated with UV light source glue and enters the mold hole of the forming mold for extrusion and stretching At the same time, the rod-shaped substrate 2 is cured by ultraviolet light, and the rod-shaped substrate 2 continues to pass through the plastic-passing equipment, and a layer of high-hardness and bending-resistant high-temperature-resistant material is hot-coated on the rod-shaped substrate 2; the plastic-coated The high-hardness and bending-resistant high-temperature-res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com