Method for preparing pre-tension membrane structure antenna

A thin-film structure and pre-tensioning technology, which is applied in antennas, antenna arrays, antenna supports/mounting devices, etc., can solve the problems of film surface forming, antenna without technical foundation, and complex precision adjustment system, and achieve weight reduction and precise control Membrane tension, the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

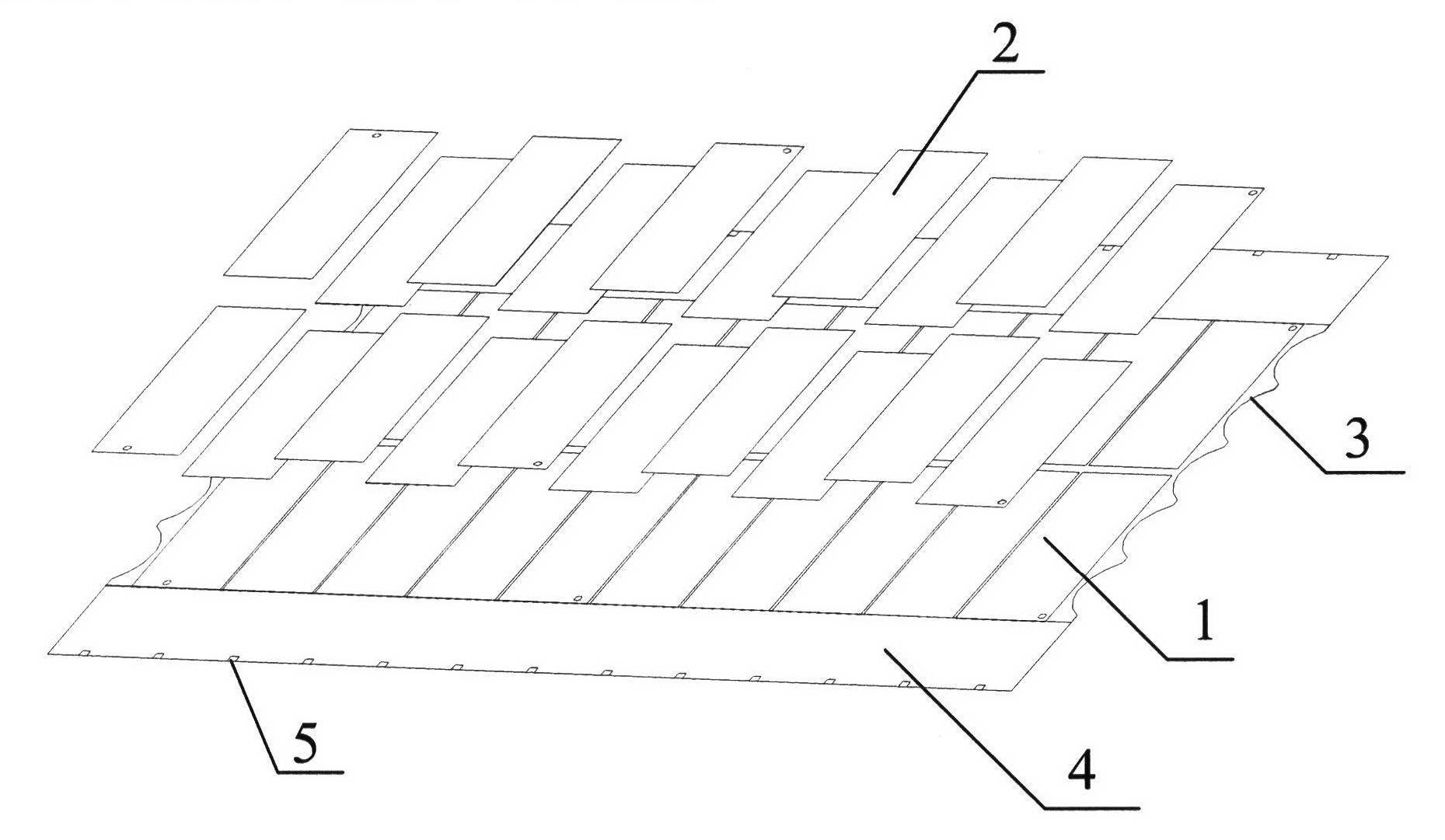

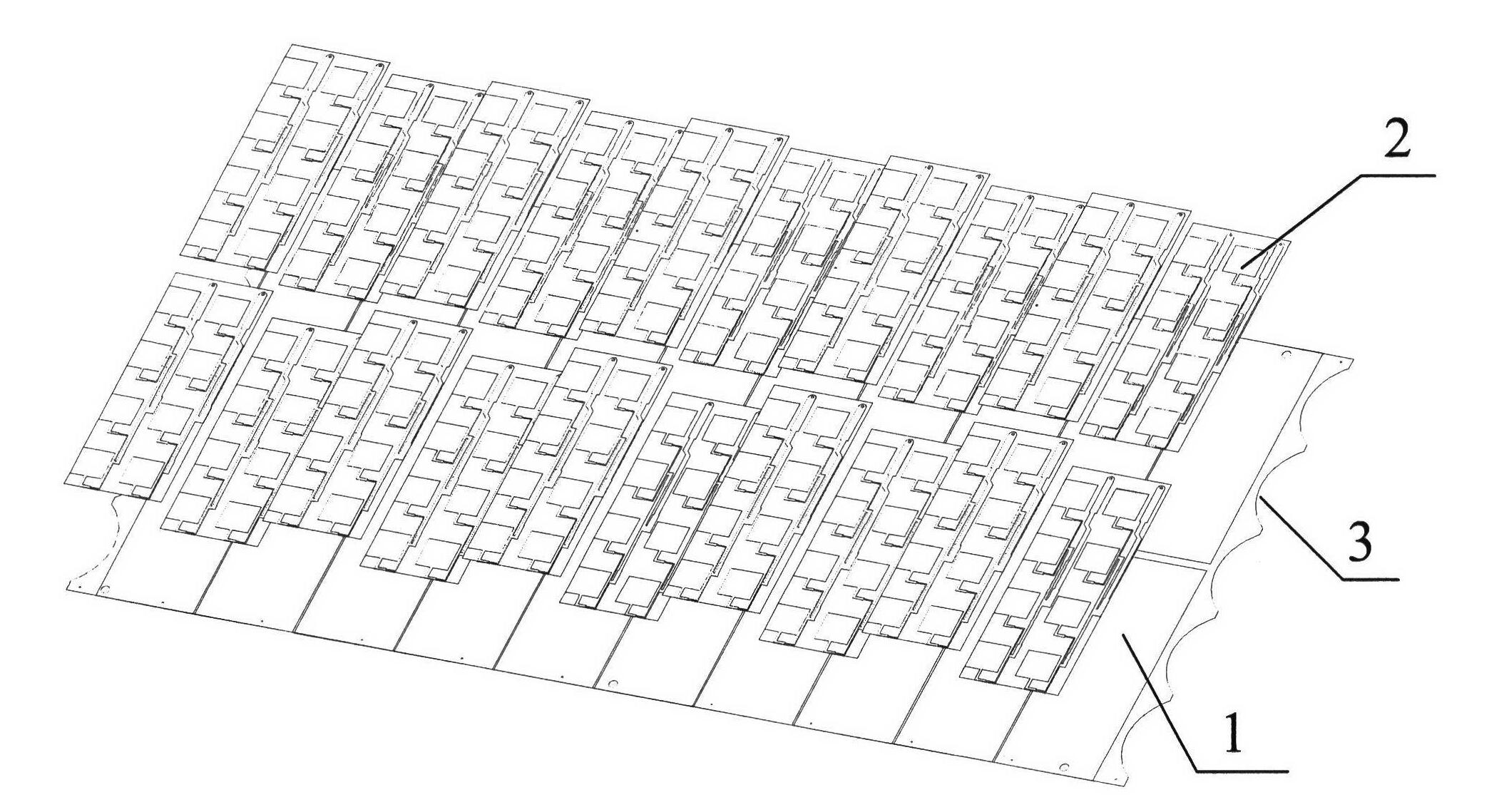

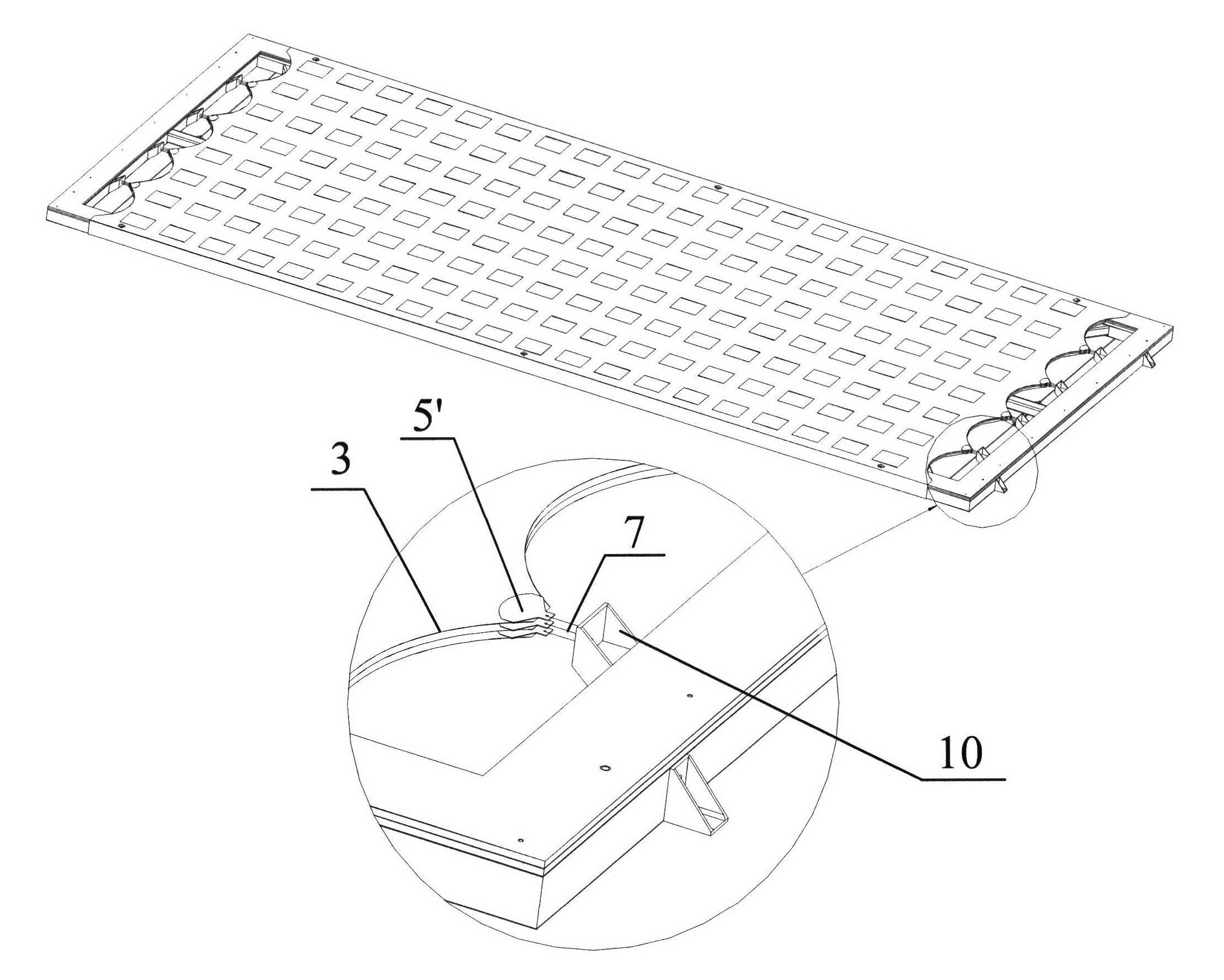

[0040] In the present invention, the film surface is designed as a base film and an electrical film, the base film is spliced and the electrical film is formed on the workbench, and the base film is marked according to the designed pasting range, and the electrical film is pasted at the corresponding position, processed. Catenary line, adhesive film auxiliary reinforcement sheet, etc., and at the same time, use the installation holes on the film antenna support frame to position the film surface, and place the first layer of film on the corresponding position of the support frame; use the auxiliary loading rope and the support frame The support carries out reverse load pretension on the long side of the membrane surface, and at the same time adjusts the pretension rope of the equipment, and adjusts it to the design position, and then glues and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com