Patents

Literature

69results about How to "Precise control of tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

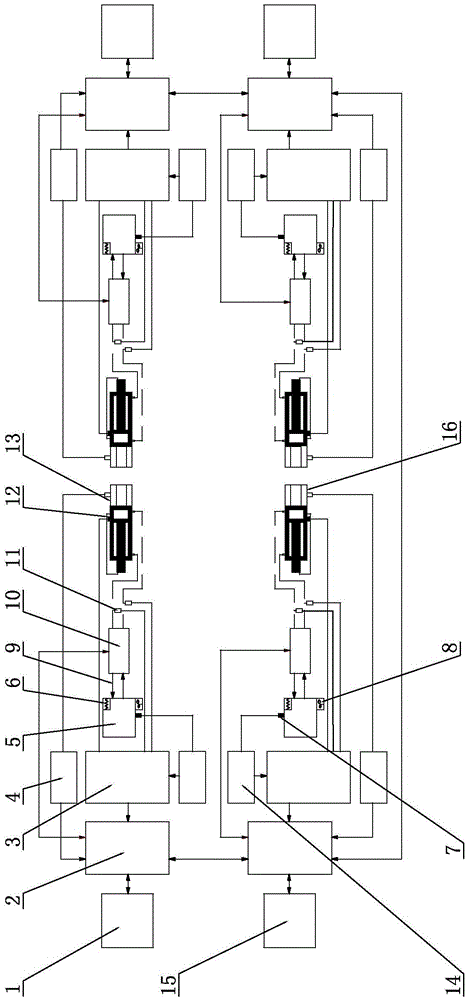

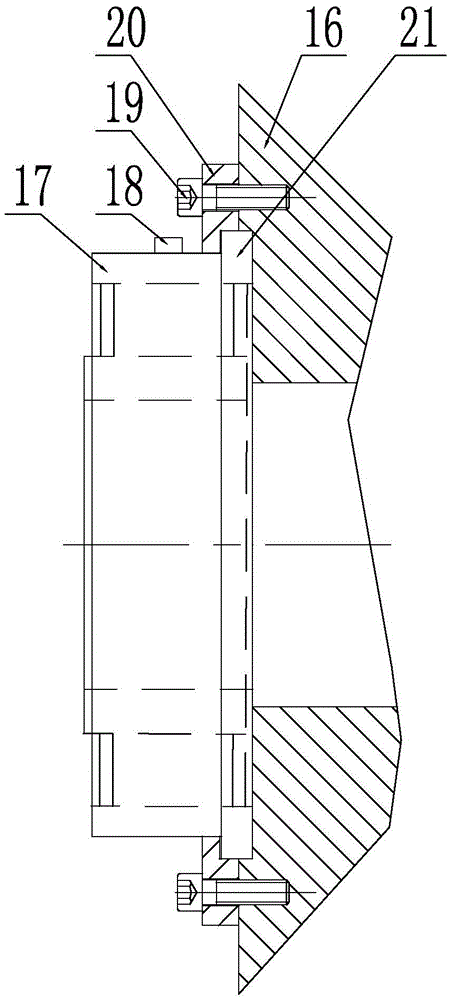

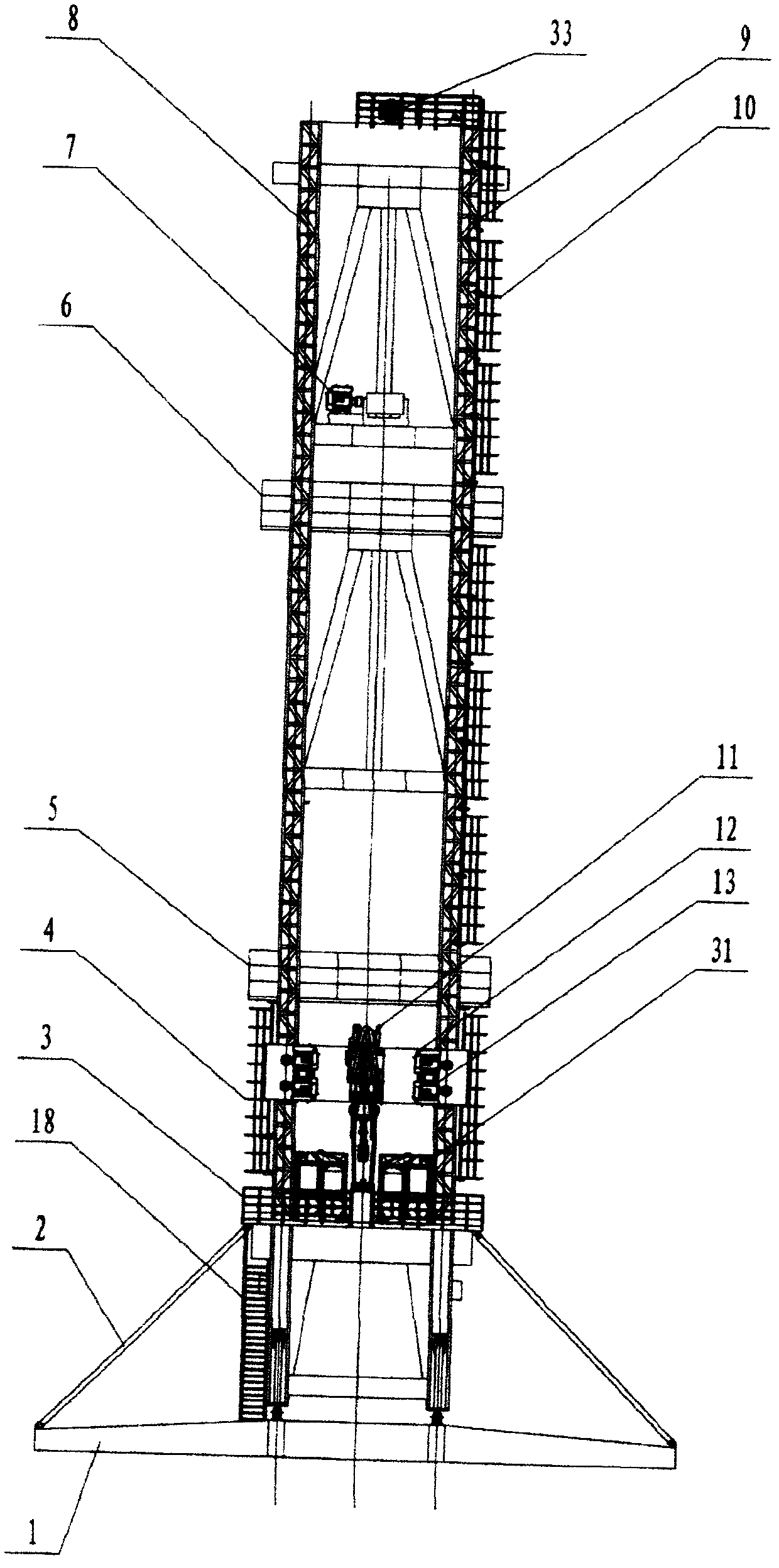

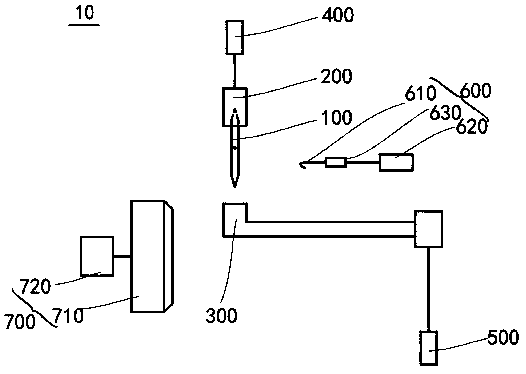

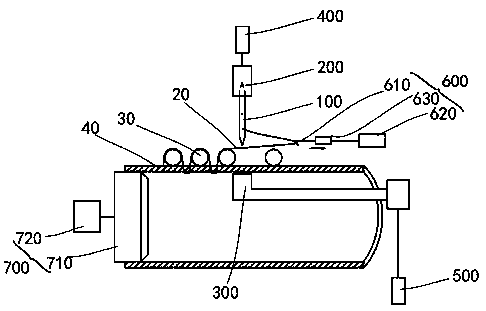

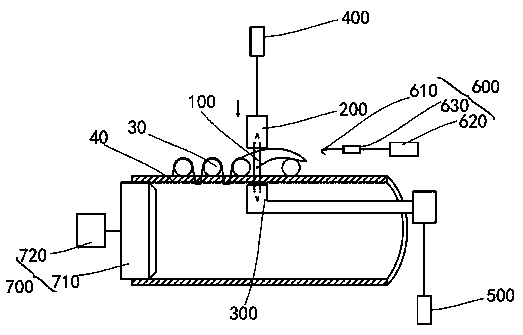

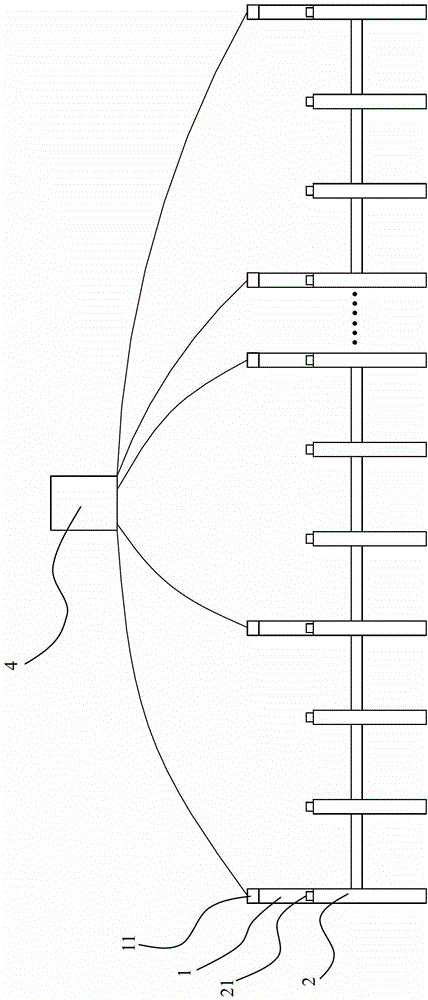

Dynamic real-time monitoring method for concrete bridge prestressed tendon tensioning force and special prestress construction system

ActiveCN105603876AWork lessEnsure construction safetyBridge erection/assemblyApparatus for force/torque/work measurementHuman–machine interfaceSecurity alarm

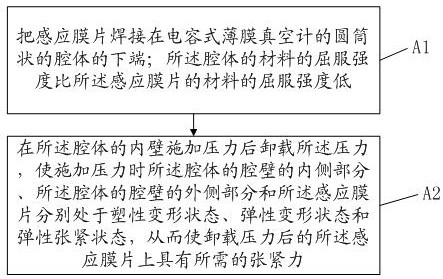

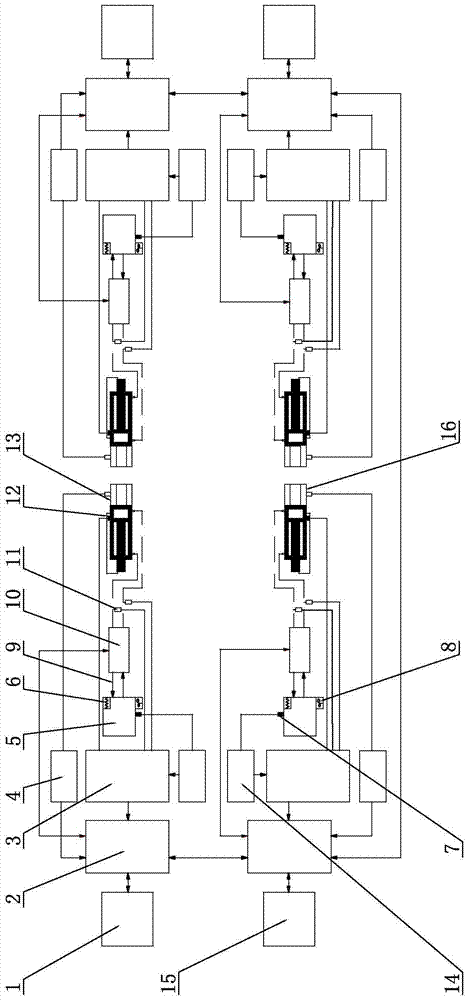

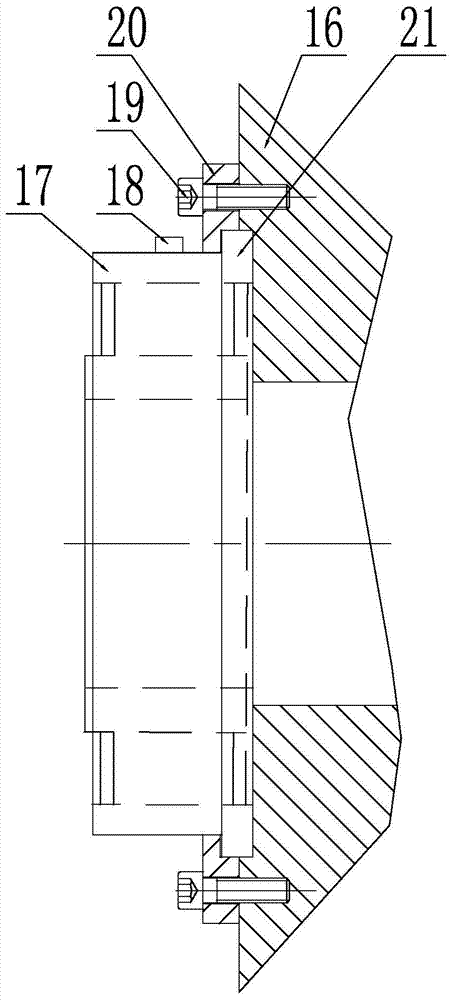

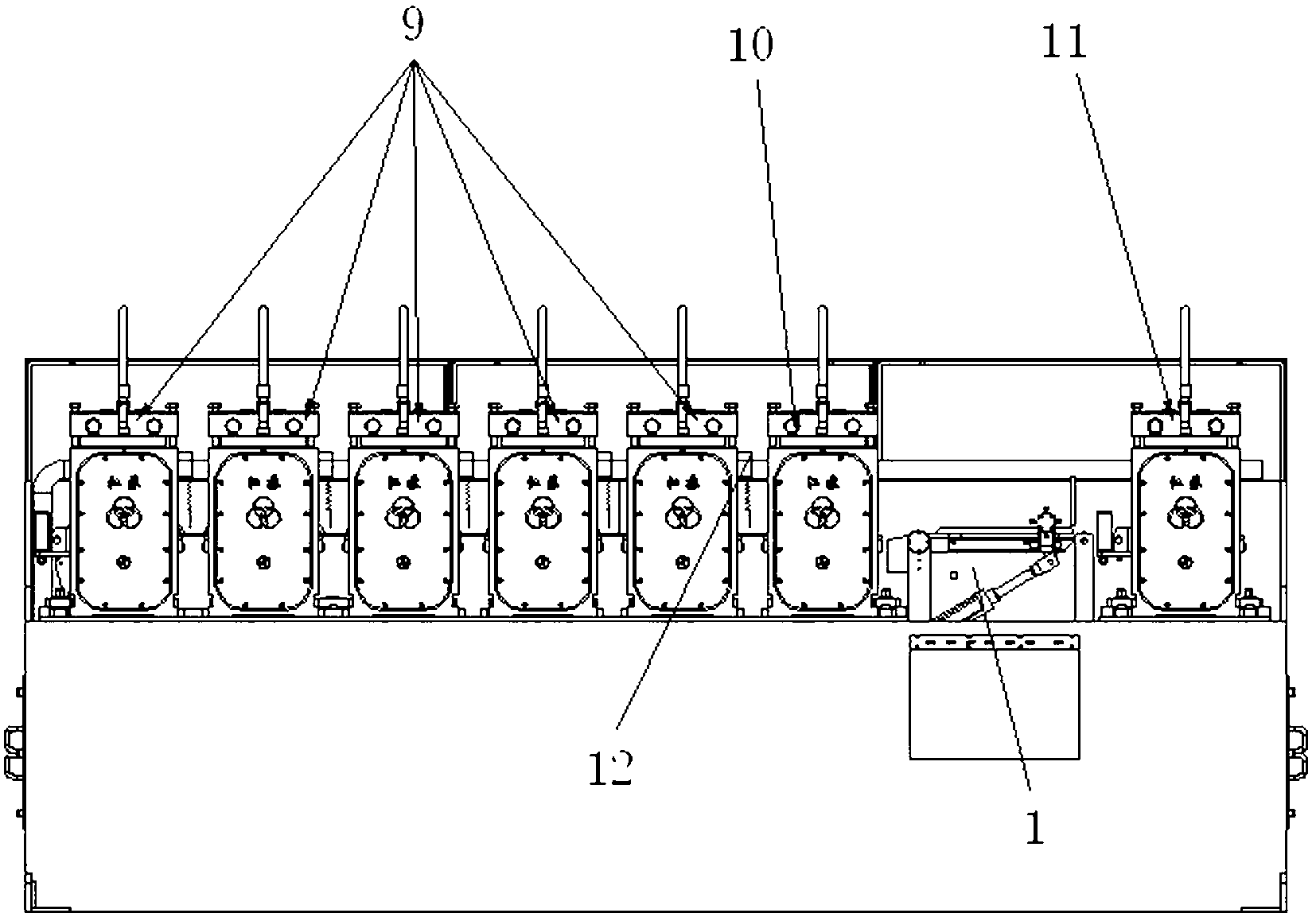

The invention belongs to bridge construction, and particularly relates to dynamic real-time monitoring method for concrete bridge prestressed tendon tensioning force and a special prestress construction system. The dynamic real-time monitoring method for the concrete bridge prestressed tendon tensioning force includes the steps of initializing and real-time dynamic control loading. The prestress construction system comprises at least one tensioning device, and each tensioning device comprises a hydraulic station, a reversing valve bank, a jack, an A / D data collecting module, a PLC, a central processing unit, a human-computer interface, a direct force measuring device, a hydraulic force measuring device, a prestressed tendon elongation measuring device, a friction resistance test device and a security alarm device. The double-control requirement, difficult to met in the prior art, for taking stress control as the principle thing and an elongation value as a checking item is met, the dynamic real-time monitoring method has the advantages that construction quality and safety can be effectively ensured, and problems found in the tensioning process can be solved in time.

Owner:CHINA RAILWAYS CORPORATION +3

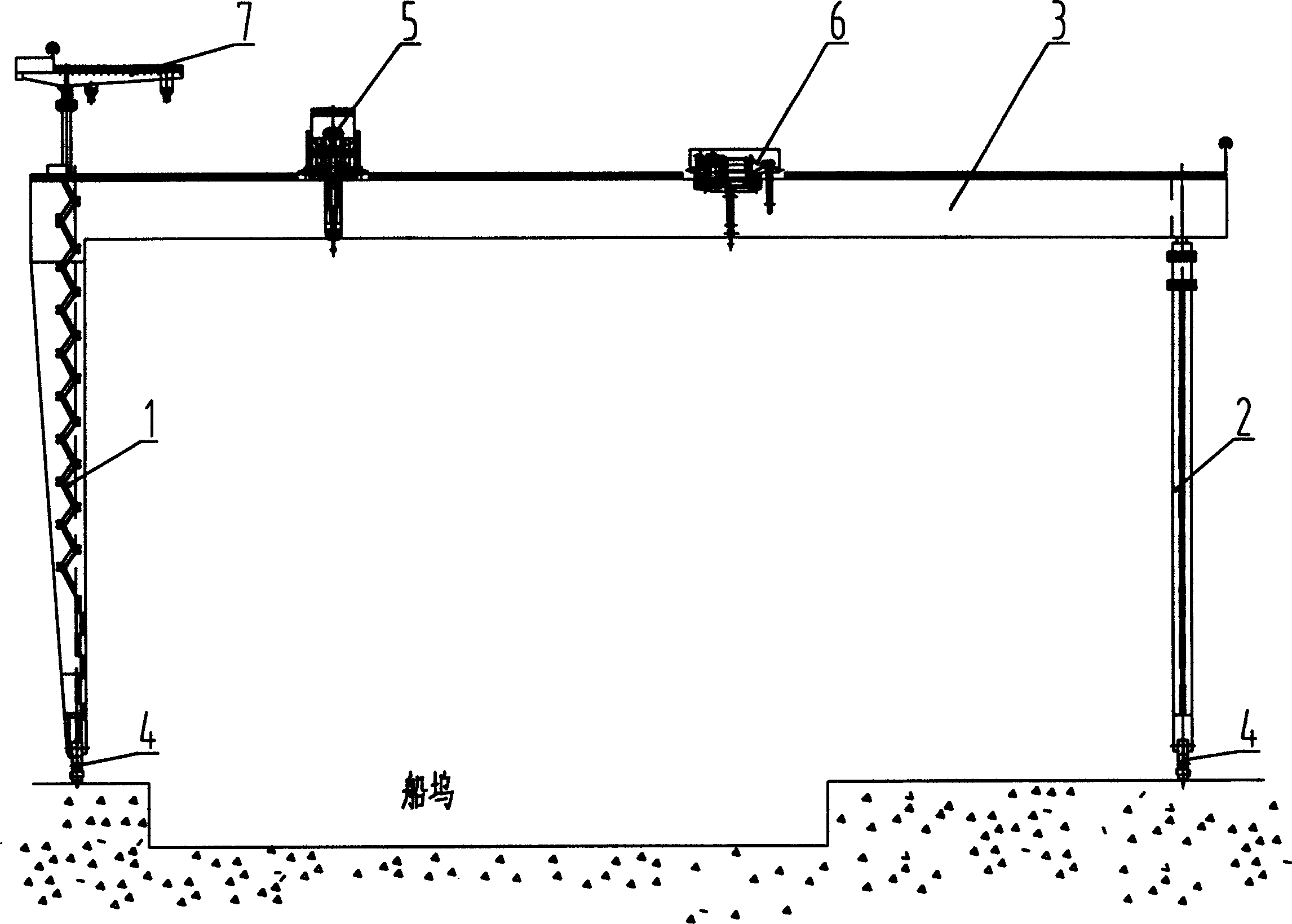

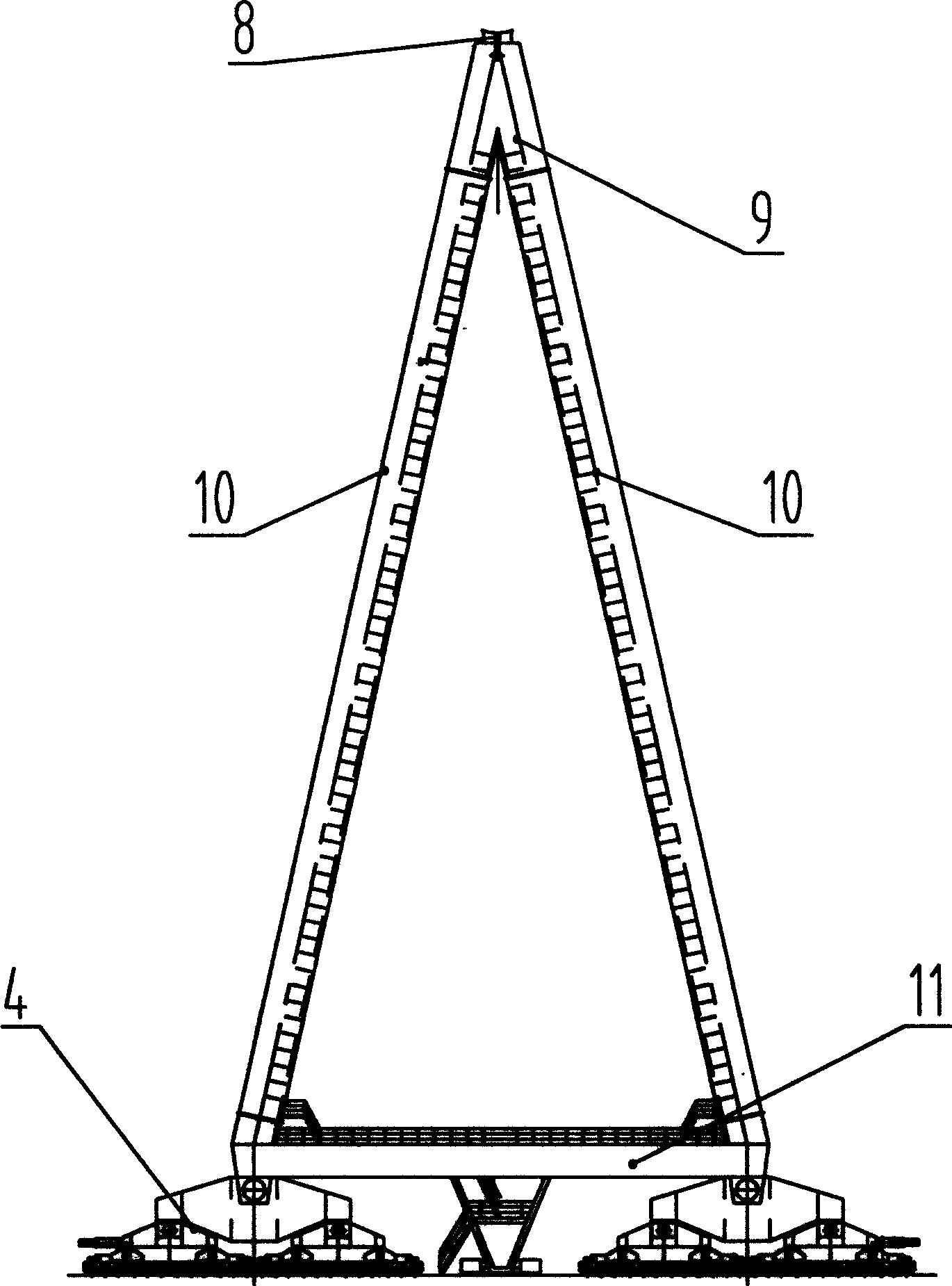

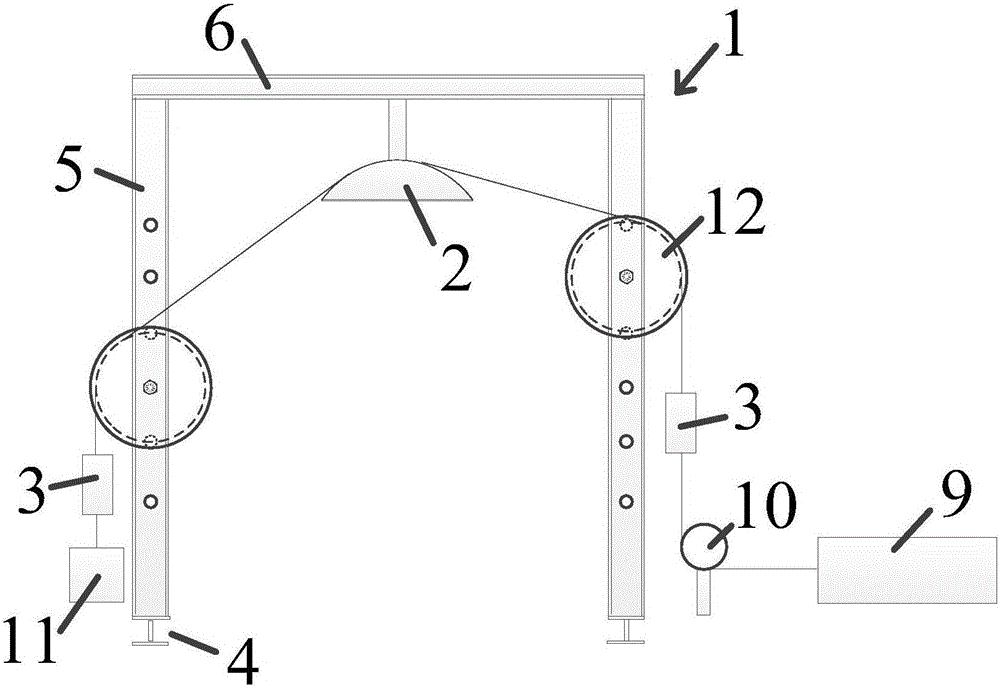

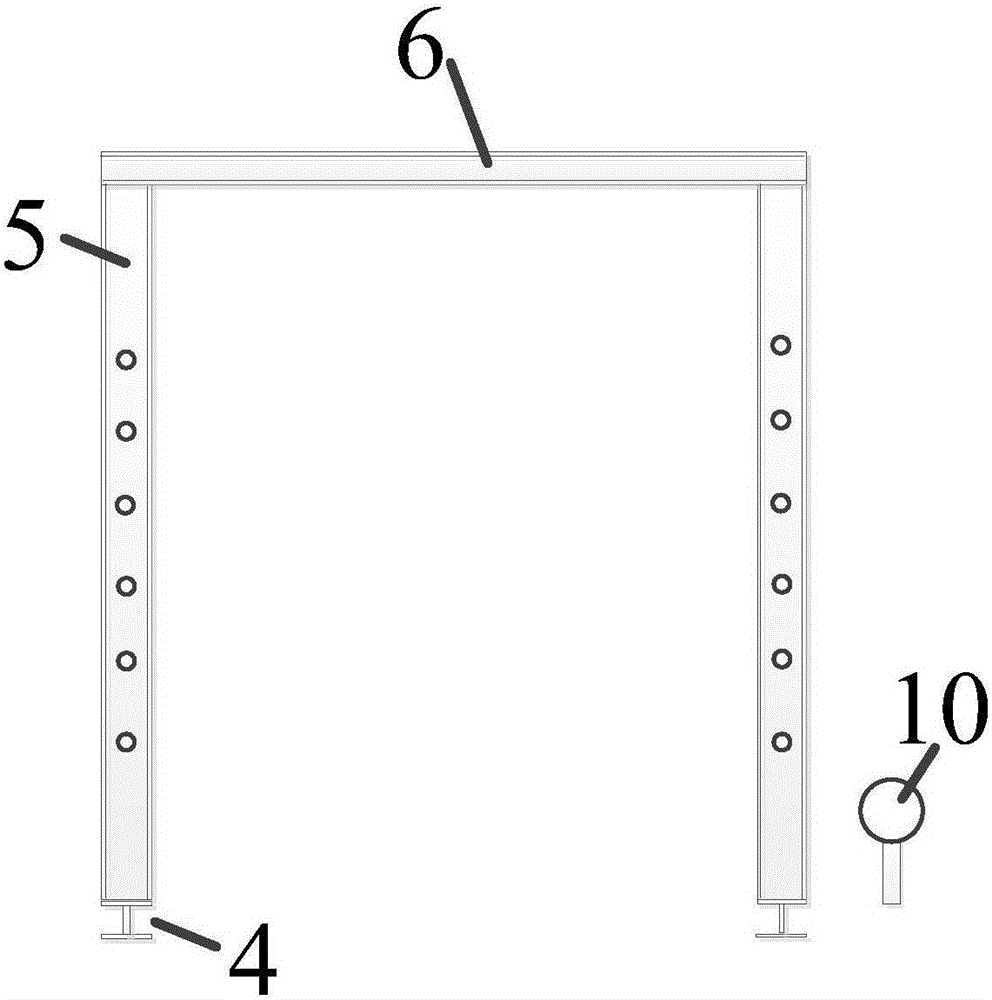

Method and apparatus for assembly of portal crane in shipbuilding

InactiveCN1463908ASolve the problem of insufficient bearing capacity of the structureEasy to useTrolley cranesButt jointEngineering

The assembling method and apparatus for ship-making portal crane features that the crossbeam rigid leg section and the flexible leg section with crossbeam raising system installed in the top are buttjointed to erected rigid leg and flexible leg; that the sections to be butt jointed are raised with the rigid leg and the flexible leg as support and hydraulic oil cylinder as raising sustained center; and that the butt joint seam is regulated by means of the hydraulic balance oil cylinder and balance twisted steel cable of the flexible hinge balance corbel system during the assembling. The saidassembling process has accurate regulation, convenient balance capacity configuration and easily controlled balance, and is stable and safe. The present invention is suitable for the assembling of large portal crane.

Owner:SHANGHAI PORT MACHINERY HEAVY IND +1

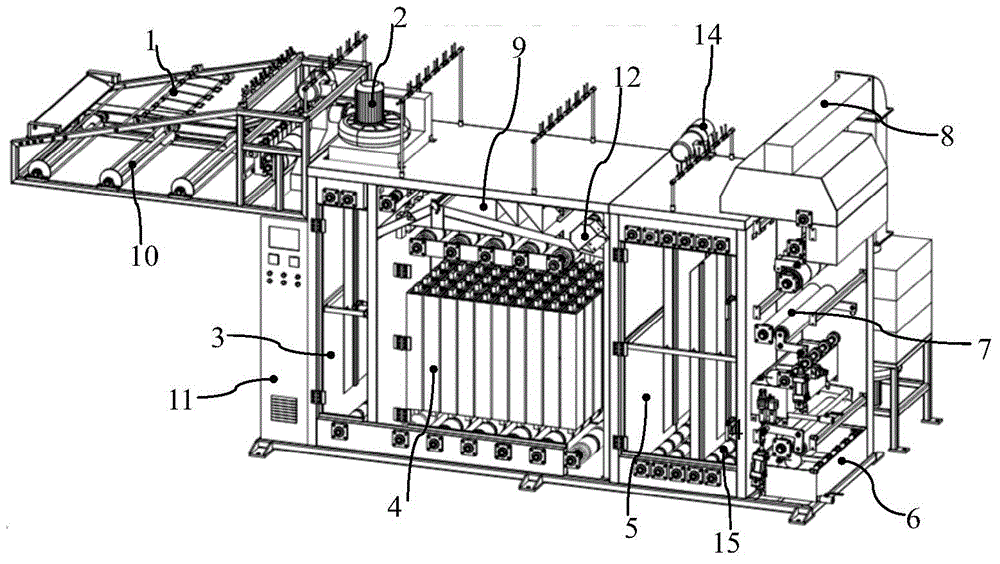

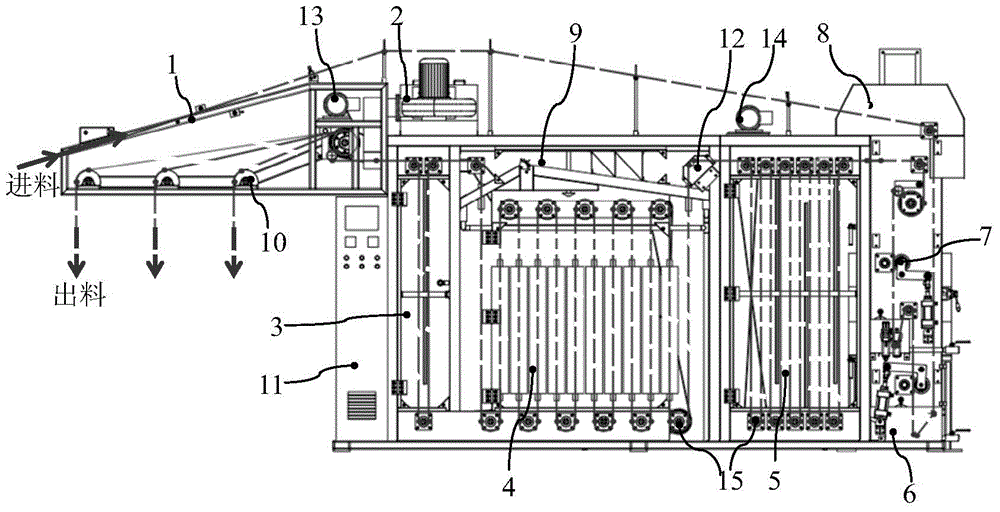

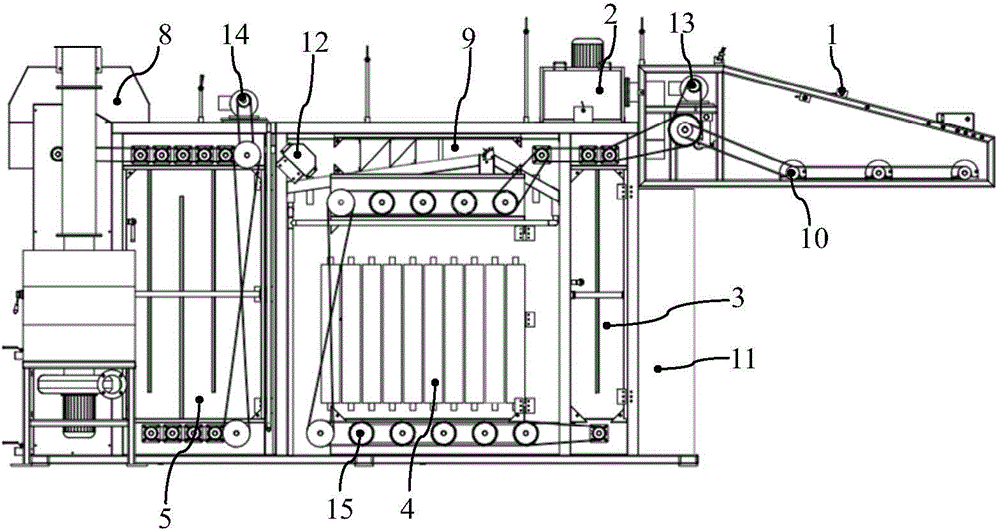

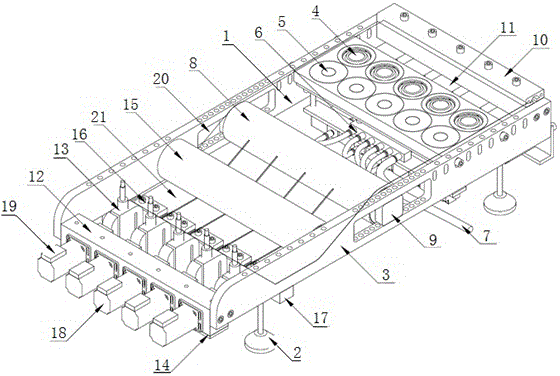

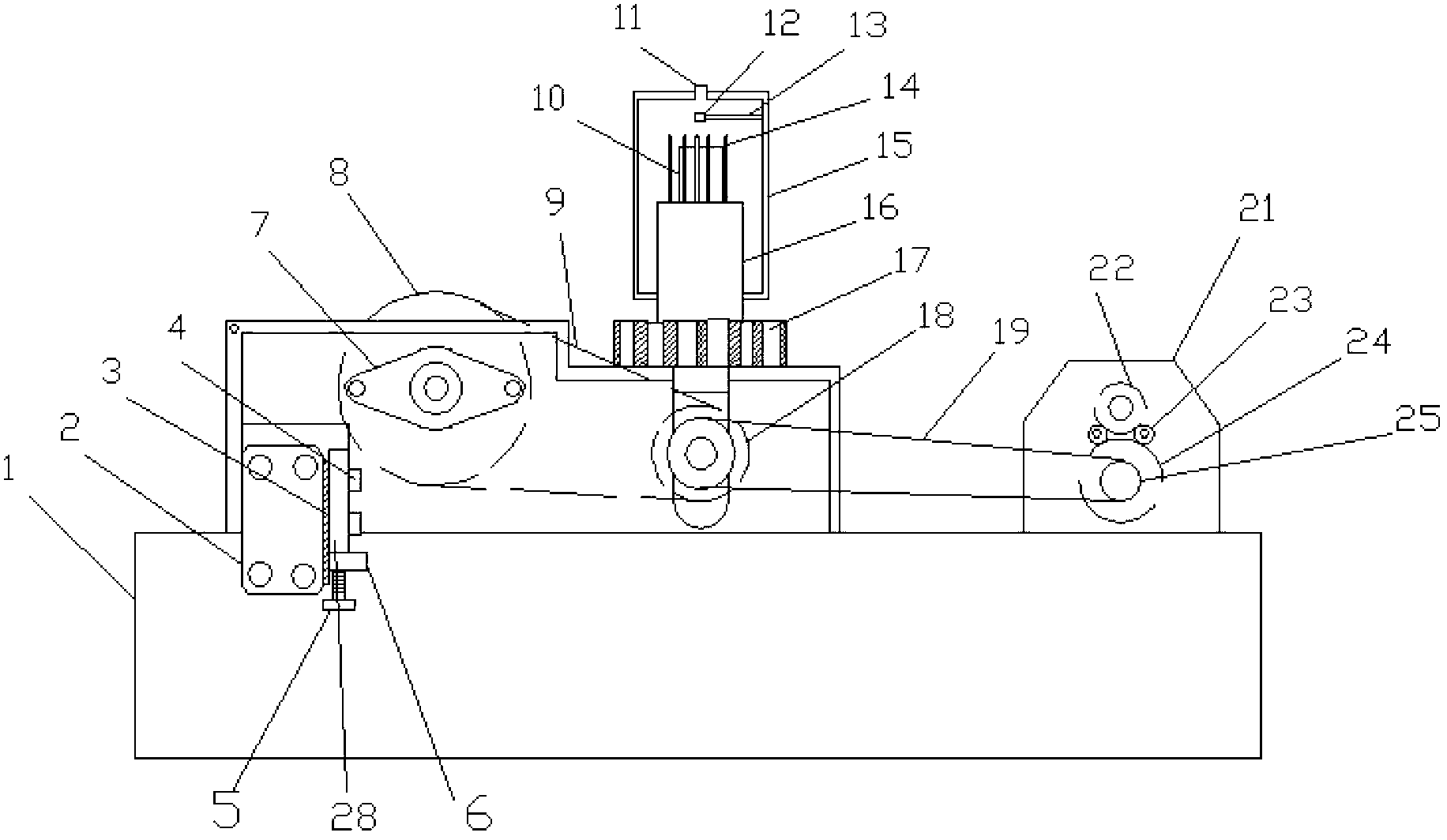

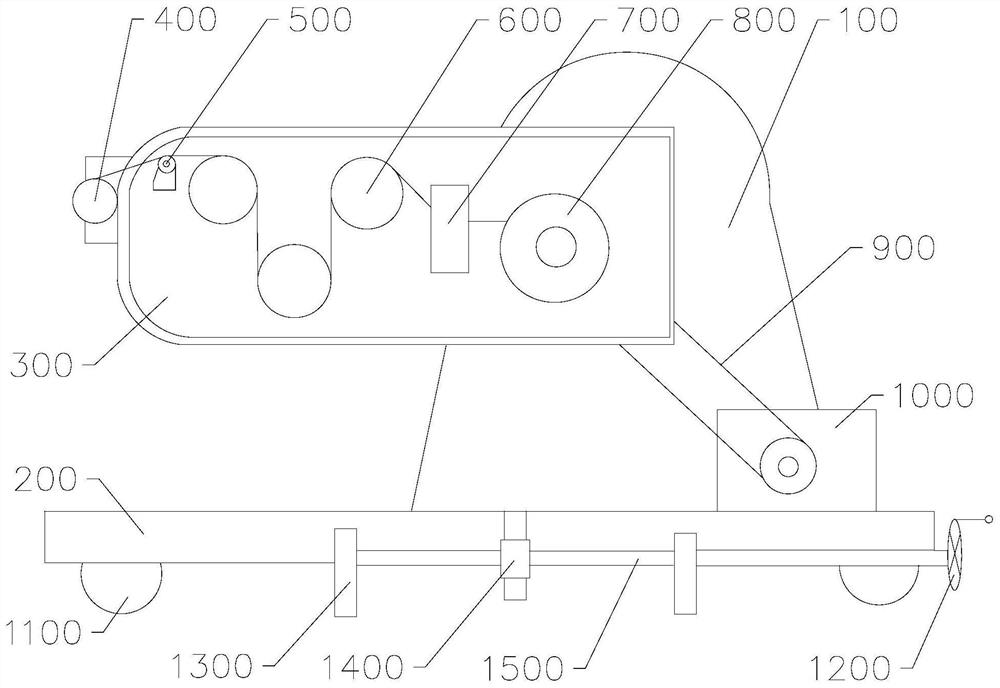

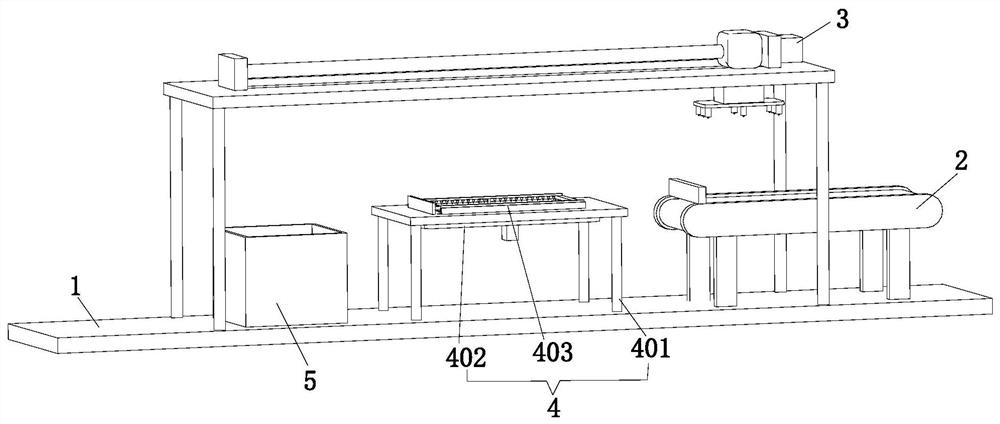

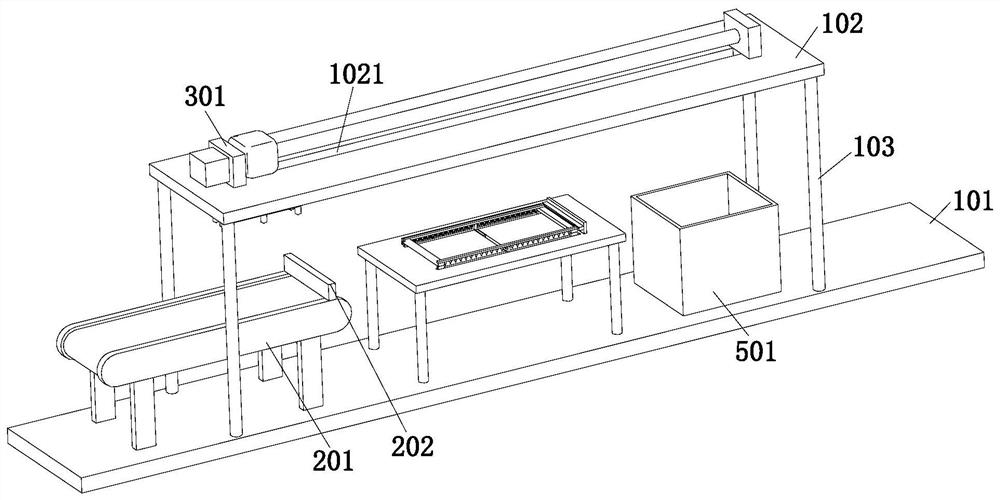

Precise intelligent fabric, braid and zipper drying and molding treating device

InactiveCN104562536APrecise control of tensionPrecise temperature controlSolvent-treatmentSucessive textile treatmentsElectricityControl system

The invention discloses a precise intelligent fabric, braid and zipper drying and molding treating device. The drying and molding treating device comprises a cloth guiding unit, a fan, a nozzle, a preheating box, a cooling box, an electromagnetic induction heating tube, an afterheat collecting pipeline, an aid tank, an aid content regulating unit, a tail gas collecting and purifying system, a cloth collecting unit, a central control system, a tensile force sensor, a front servo motor or a variable-frequency control motor, a rear servo motor or a variable-frequency control motor, a driving shaft and the like. The treating device disclosed by the invention is ingenious in structural design, and can be used for precisely controlling tensile force of a fabric, a braid and a zipper during control, and processing and guaranteeing precise control on the shrinkage rate of the fabric, the braid and the zipper, wherein the shrinkage rate can be effectively controlled within a range of 0% to 0.2%. The treating device disclosed by the invention is also used for precisely heating the fabric, the braid and the zipper, is high in heating speed and high in safety, can be used for implementing the precise control by the central control system and recycling afterheat by utilizing an afterheat recycling system, and can save more than 30% of electricity in comparison with that when a traditional heating method is adopted.

Owner:高勋绿色智能装备(广州)有限公司

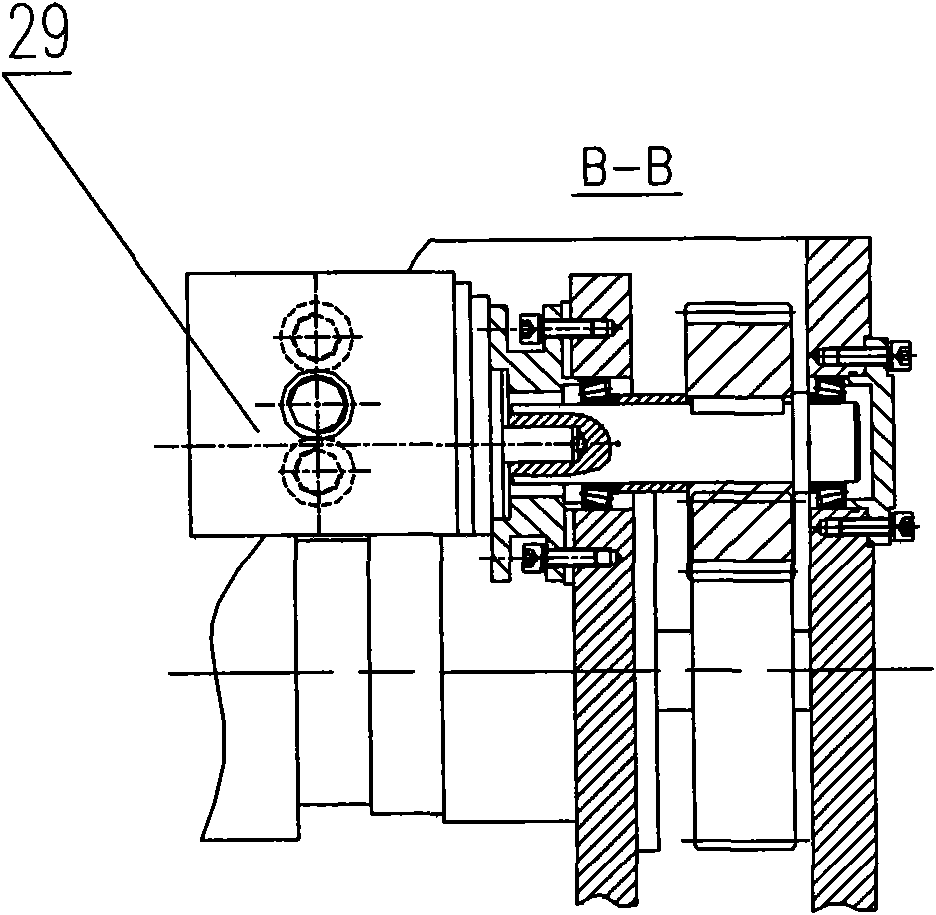

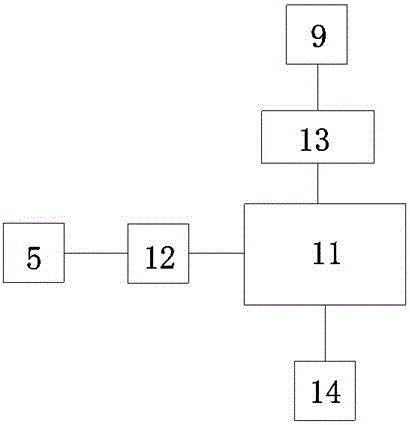

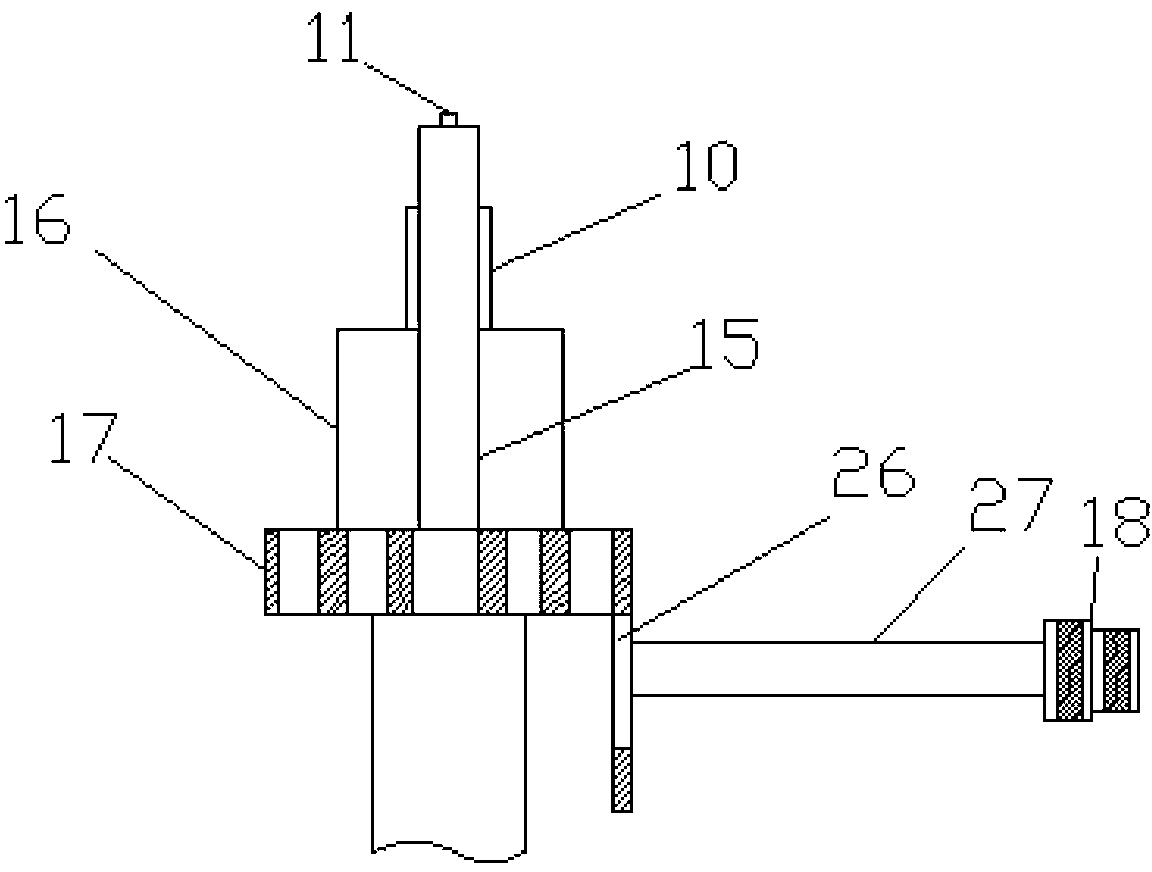

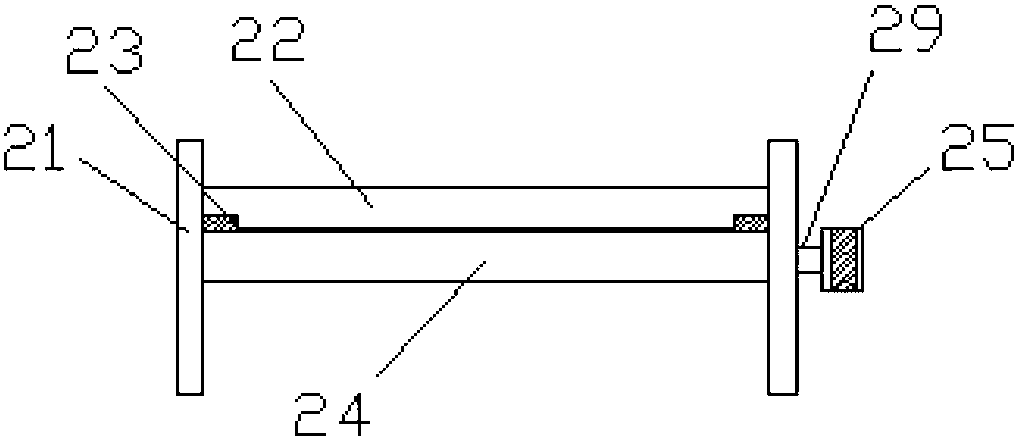

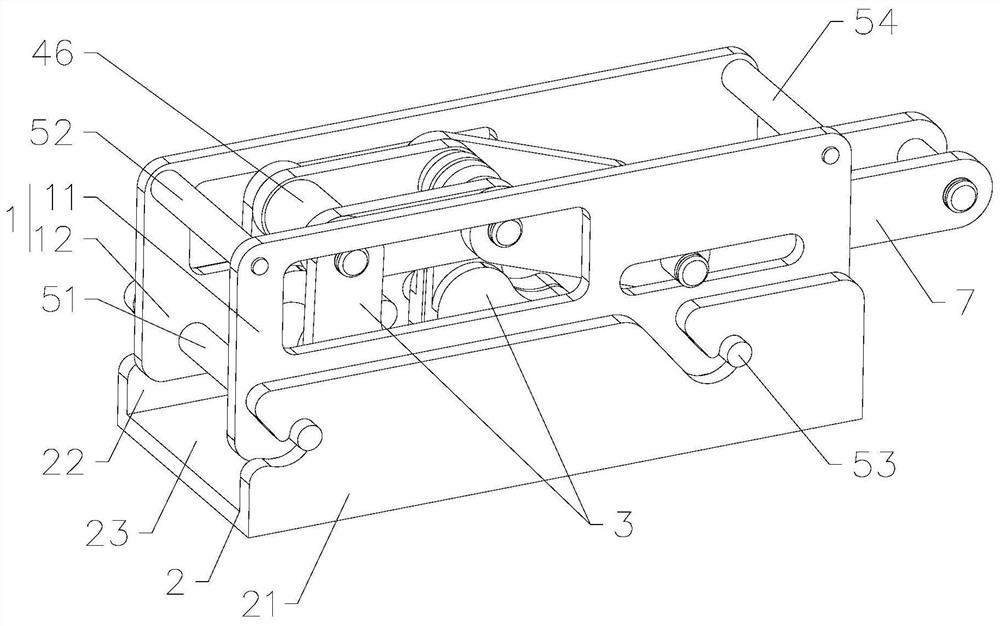

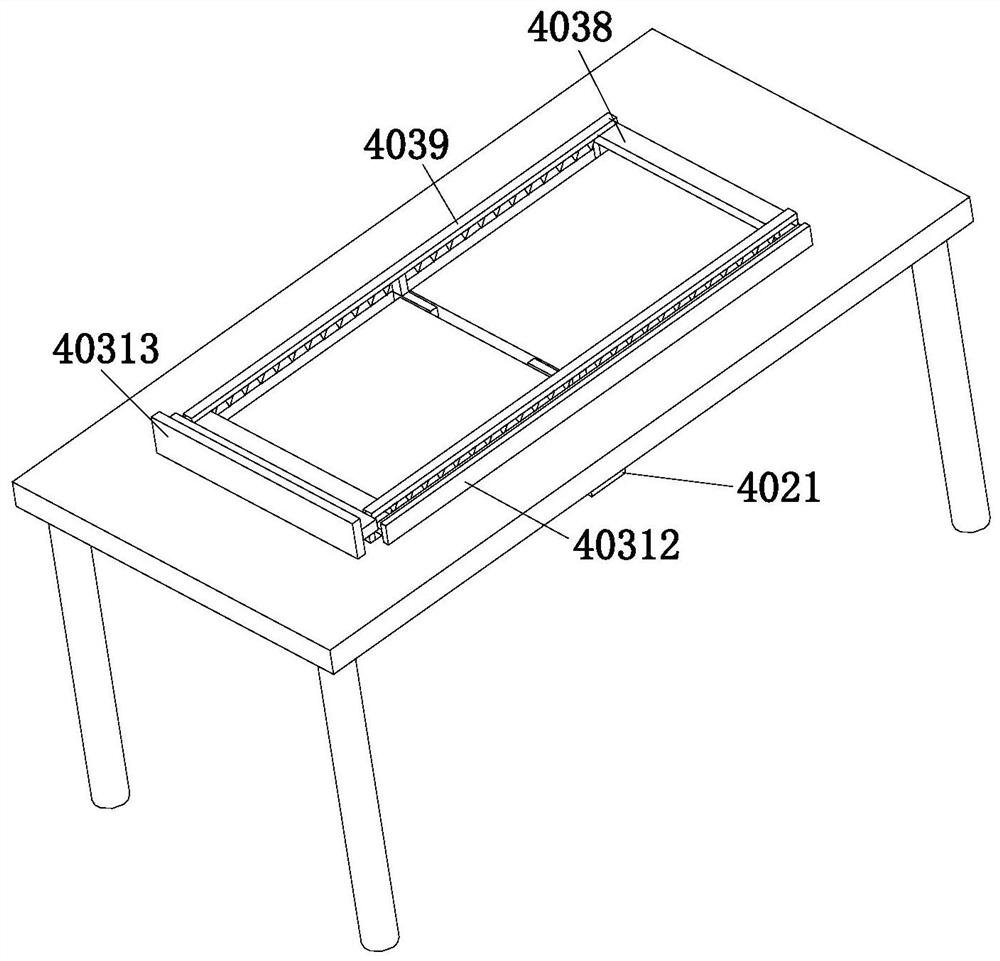

Chain transmission tensioning device

InactiveCN107514446AImprove the tension effectAccurate Watch Movement ValuesGearingDrive shaftSlide plate

The invention is mainly applied to the field of chain transmission equipment in the mining industry, and particularly relates to a chain transmission tensioning device, which includes a tensioning wheel, the tensioning wheel is connected to a connecting rod, the connecting rod is connected to a rack, and a slider is arranged at the bottom of the rack. Installed on the skateboard, the slider on the skateboard is provided with a chute, the rack and the gear are meshed, the gear is connected to the driving device through the transmission shaft, the transmission shaft is installed on the bearing seat through the bearing, and the bearing seat and the driving device are installed on the skateboard. A mounting plate is provided at the bottom, a sliding assembly is provided between the sliding plate and the mounting plate, a cylinder is provided on one side of the sliding plate, and the cylinder is installed on the mounting plate. The invention drives the gear to rotate through the driving device, and then drives the rack to move, realizes the movement of the upper and lower positions of the tension wheel, achieves the purpose of tensioning the chain, improves work efficiency and work quality, and can precisely control the tension.

Owner:SHANDONG HUALIAN MINING

Friction test device for steel wire rope

ActiveCN105842154ALow area costReduce use costUsing mechanical meansMaterial analysisEngineeringFriction test

The invention relates to a friction test device for a steel wire rope. The steel wire rope includes a center steel wire and an outer steel strand arranged around the steel wire. The friction test device comprises a fixed rack and a test assembly arranged on the fixed rack, the fixed rack is provided with a saddle connected to the steel wire rope, and the test assembly is provided with a tension meter. The friction test device for the steel wire rope provided by the invention can test the friction coefficient and slip characteristics of the steel wire rope and the saddle, reduce the floor space and use cost of the test device, and improve the similarity of test data and actually used data.

Owner:CHINA ELECTRIC POWER RES INST +1

Binding packaging device

ActiveCN106428993APlay a protective effectAvoid over-tighteningPackage recyclingFlexible elementsEngineeringConductor Coil

The invention relates to the technical field of packaging, in particular to a binding packaging device. The binding packaging device comprises a base, a rope winding spool, a rope winding knob and an adjusting knob. According to the binding packaging device, when the predetermined rope tension is achieved, a worker continues rotating the rope winding knob in the packaging process, due to the fact that the phenomenon of skid between a first chuck and a second chuck exists, the operation of tightening a rope cannot continue, the phenomenon that binding is too tight is avoided, and the effect of protecting a bound object is achieved. When a package is removed, the rope does not need to be cut off or destroyed, the worker only needs to rotate the rope winding knob in the opposite direction, the rope can be loosened, removal is convenient, the rope can be reused, and resources are saved. In addition, the degree of meshing between the first chuck and the second chuck can be controlled through the adjusting knob, then the tension of the rope, namely the packaging tightness degree, can be accurately controlled, control is easy, operation is convenient, and the packaging tightness degree can be accurately controlled. By the adoption of the binding packaging device, quick packaging can be achieved, the worker does not need to worry about excessively tight packaging, and the packaging efficiency is extremely high.

Owner:ZHEJIANG SHENGHUABO ELECTRICAL APPLIANCE

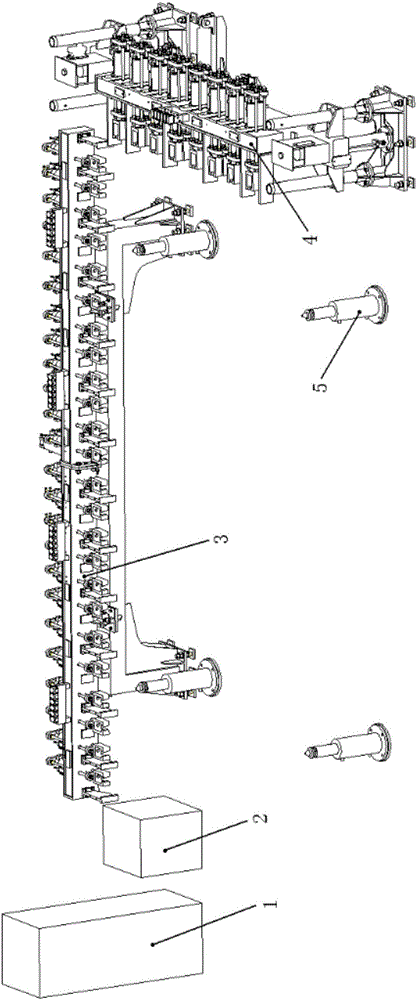

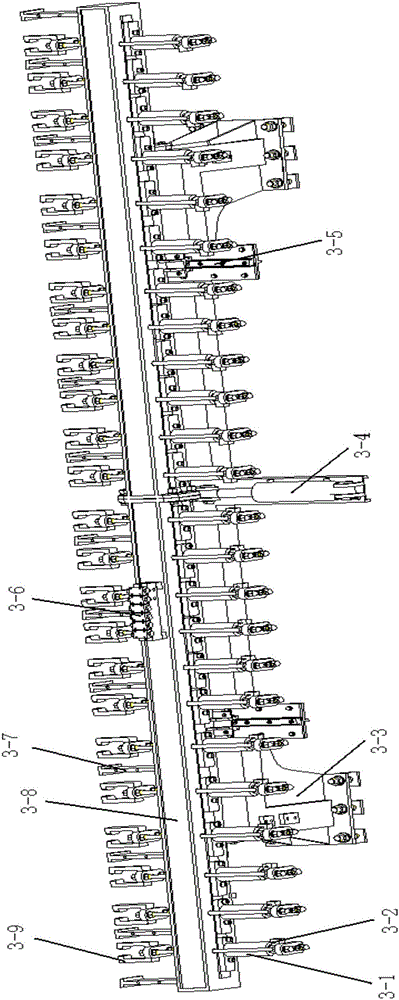

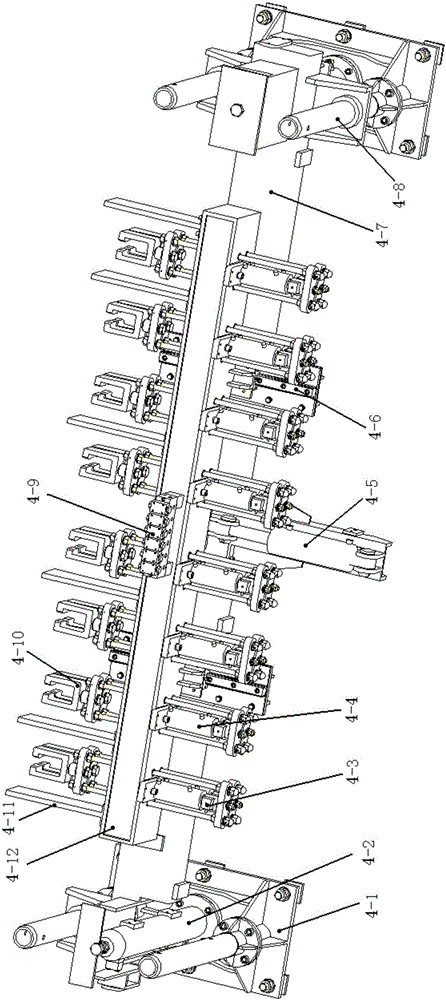

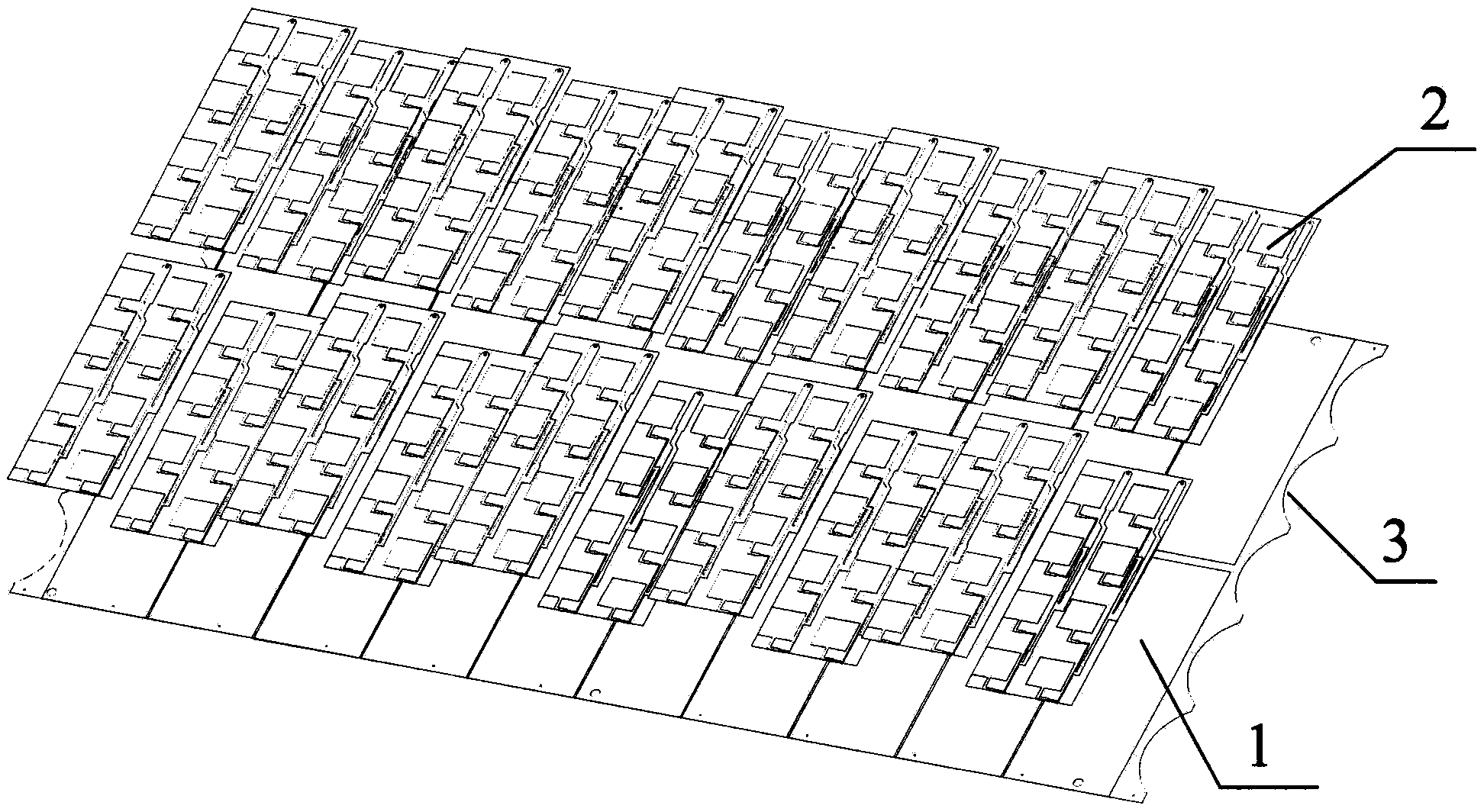

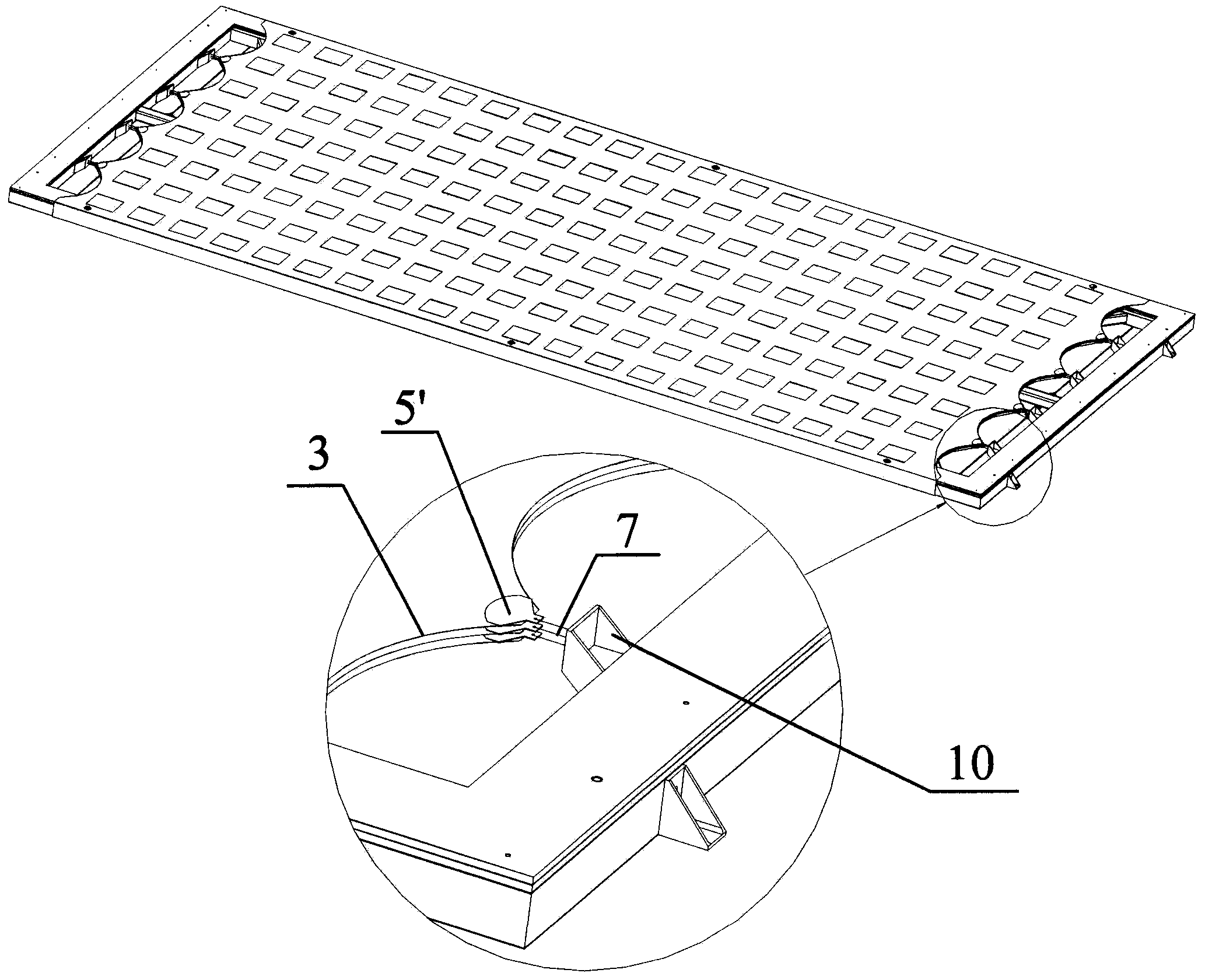

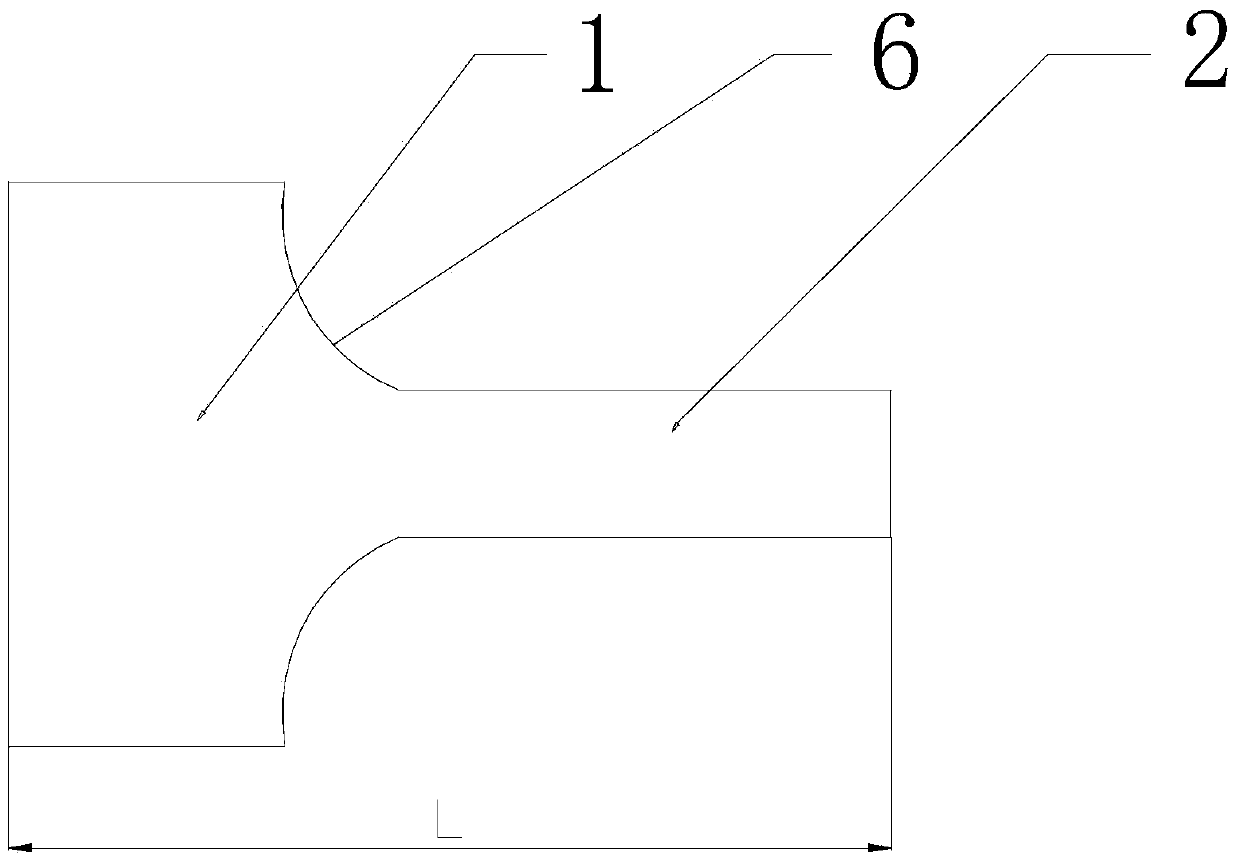

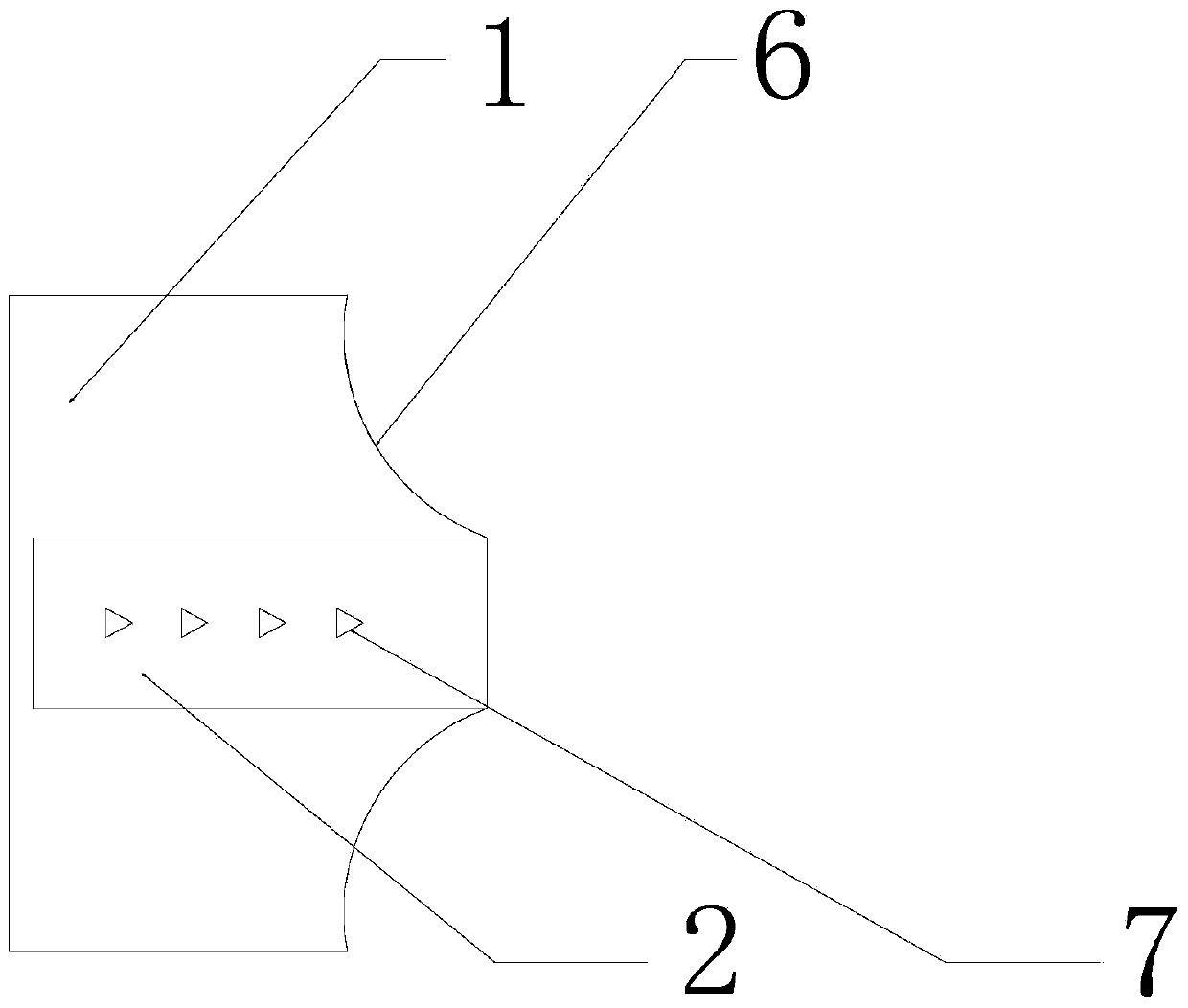

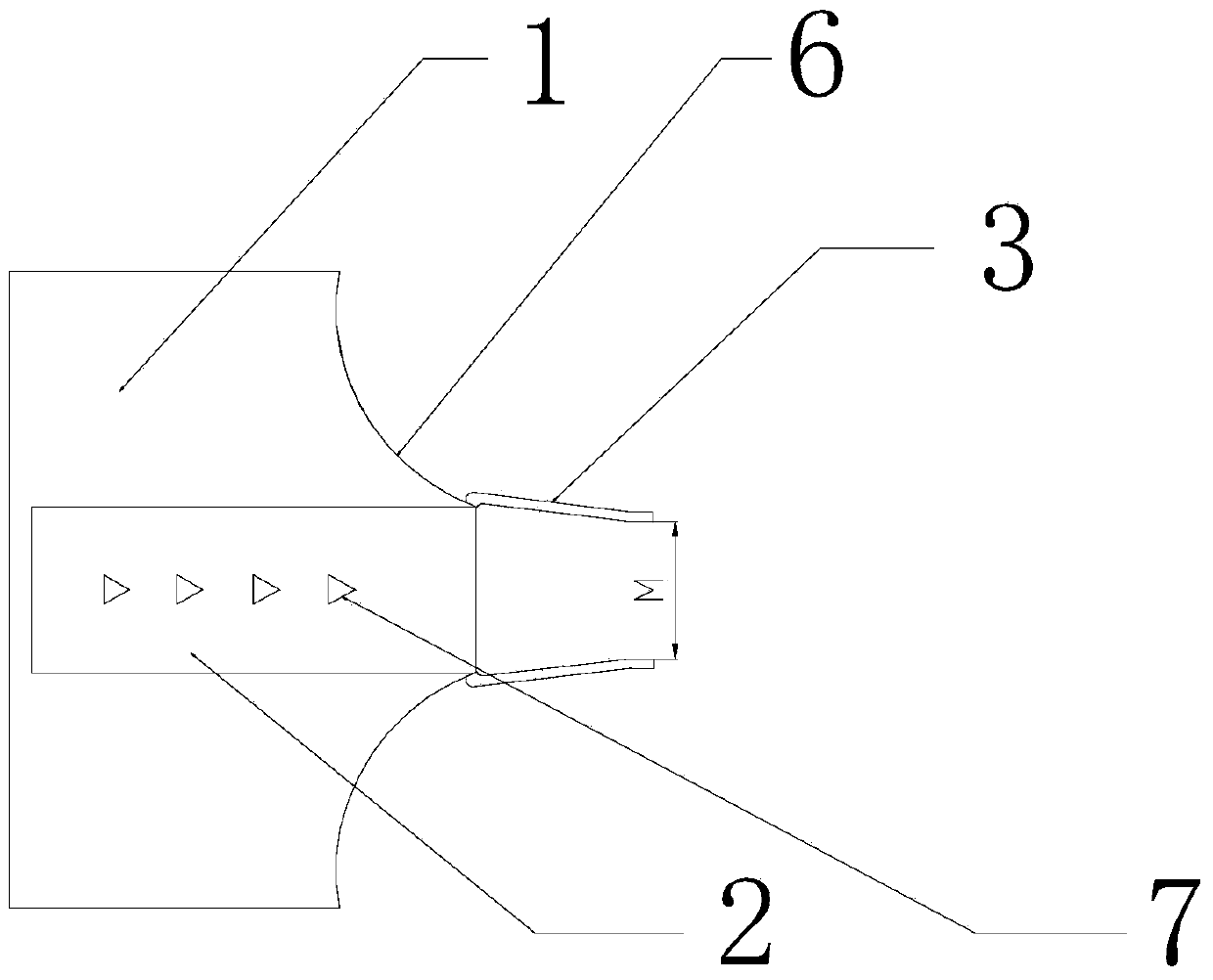

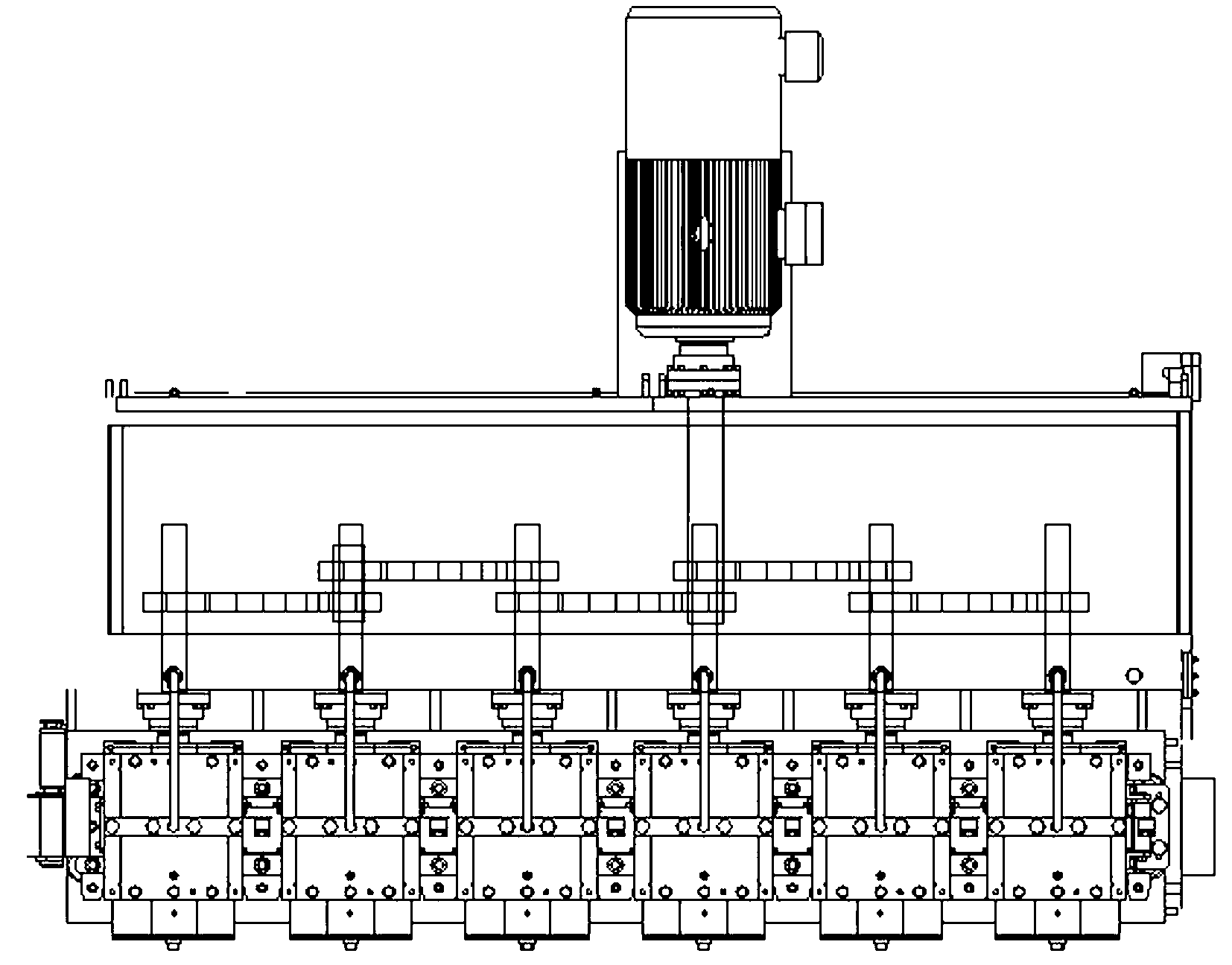

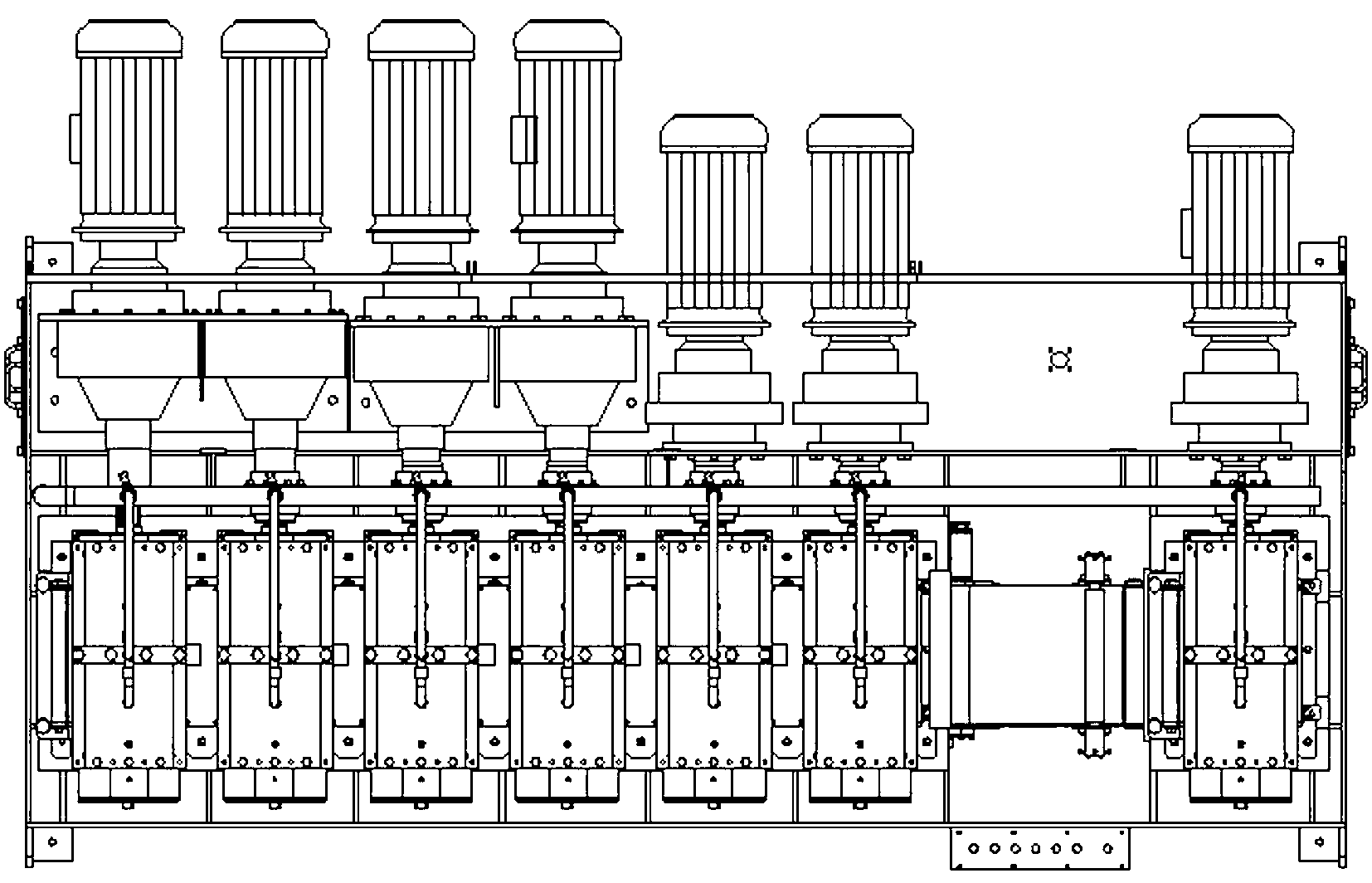

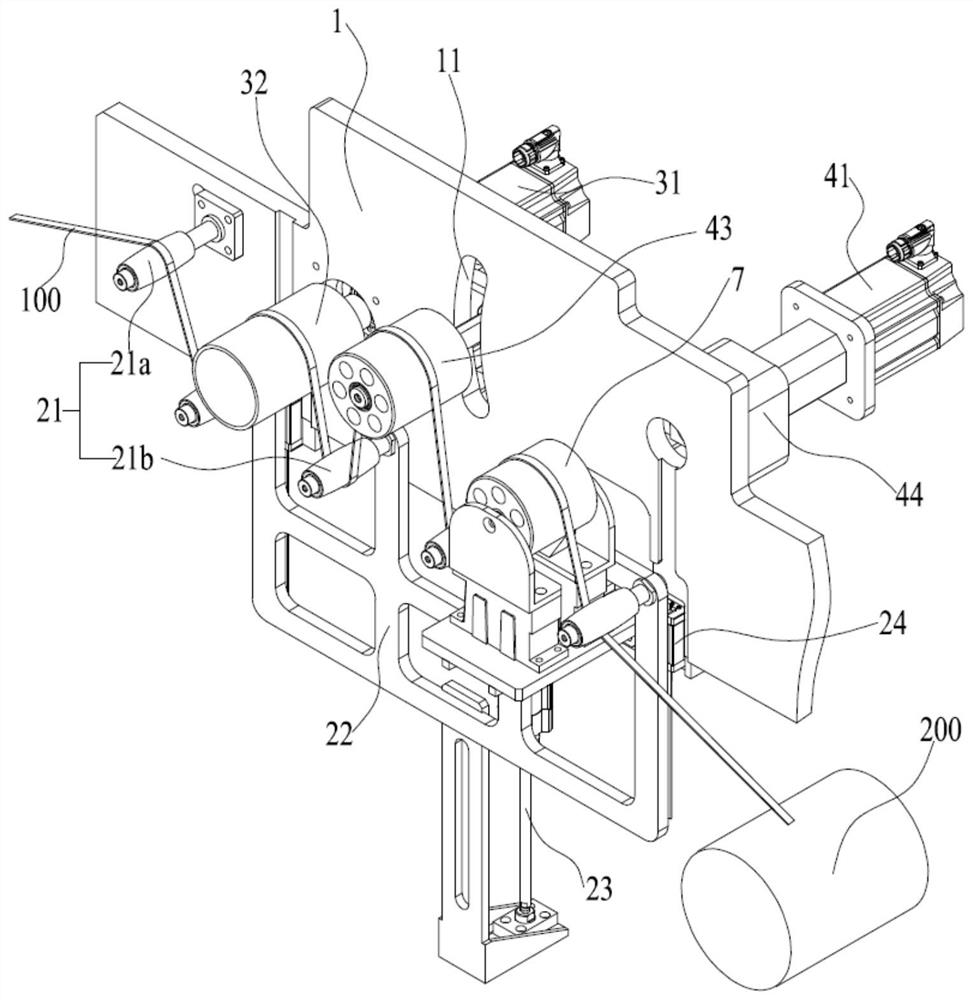

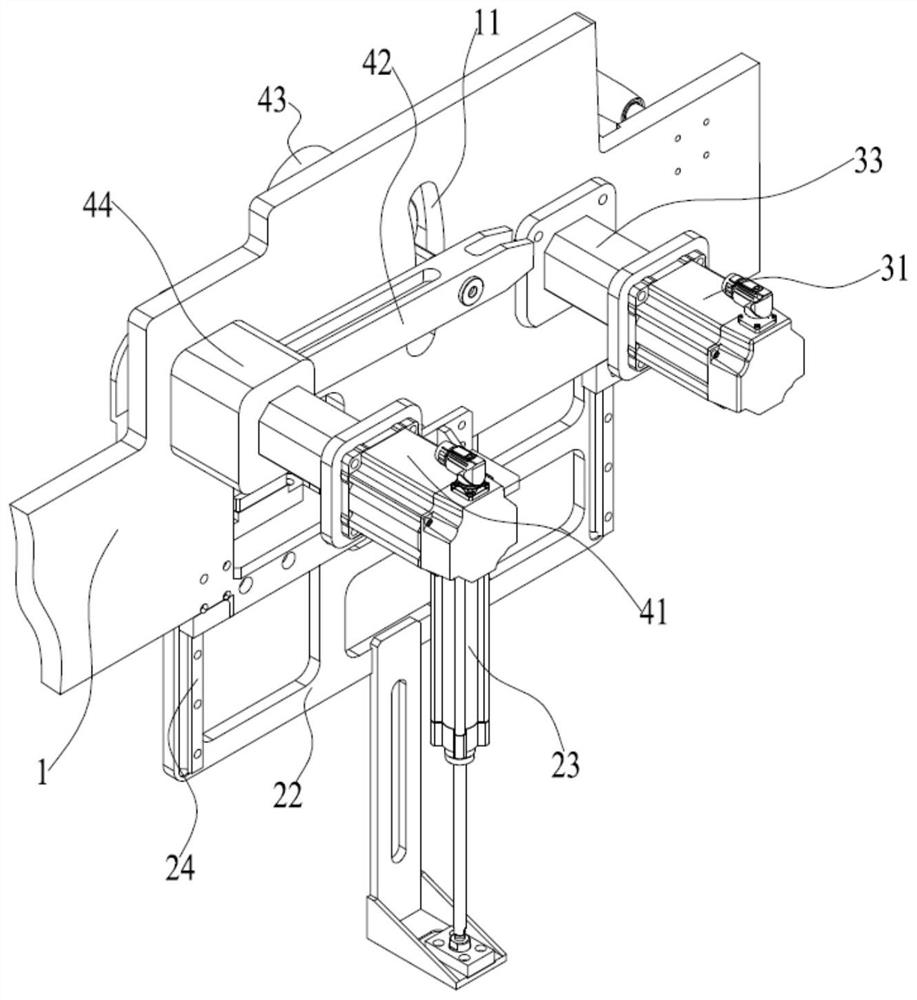

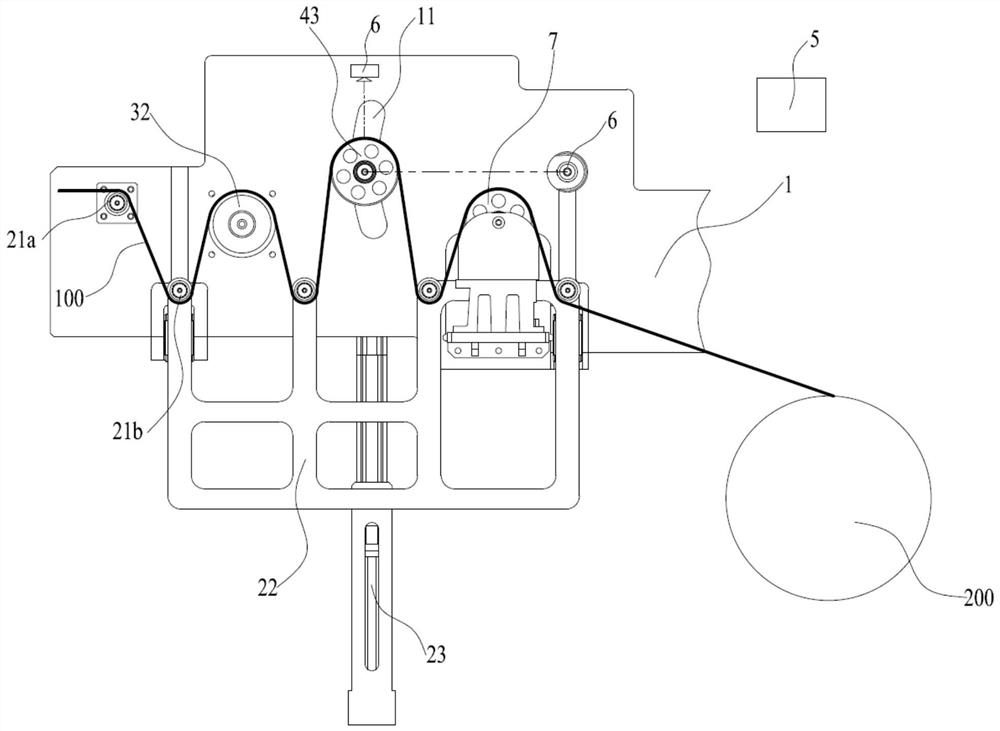

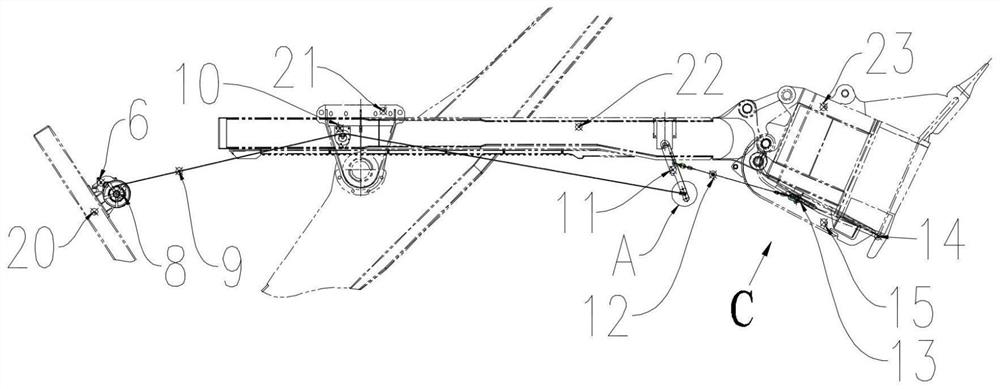

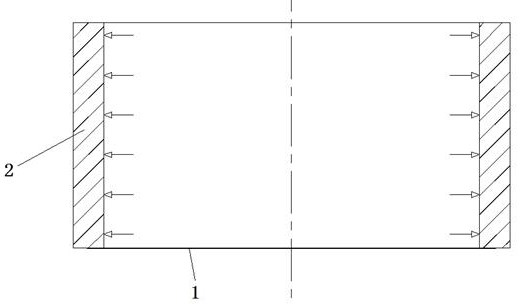

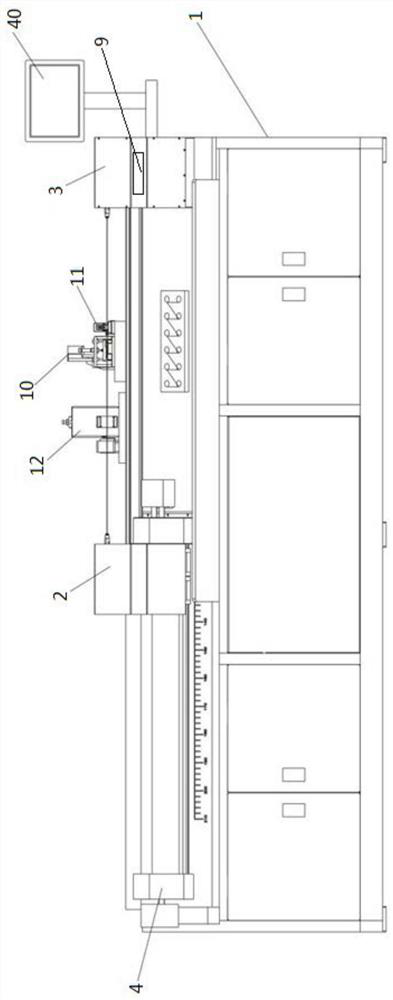

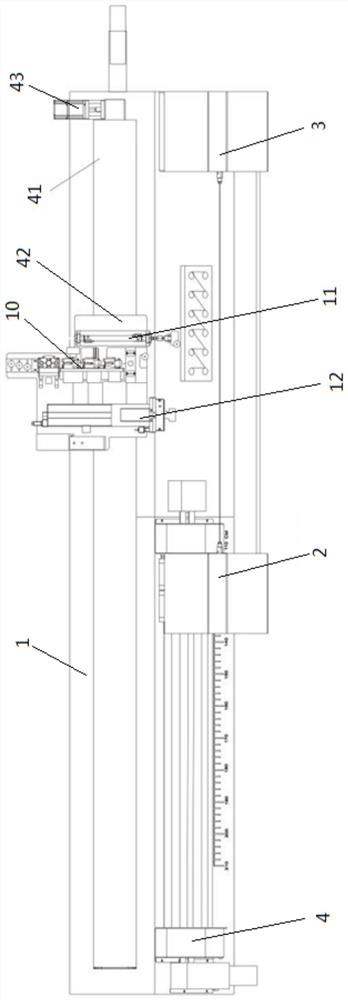

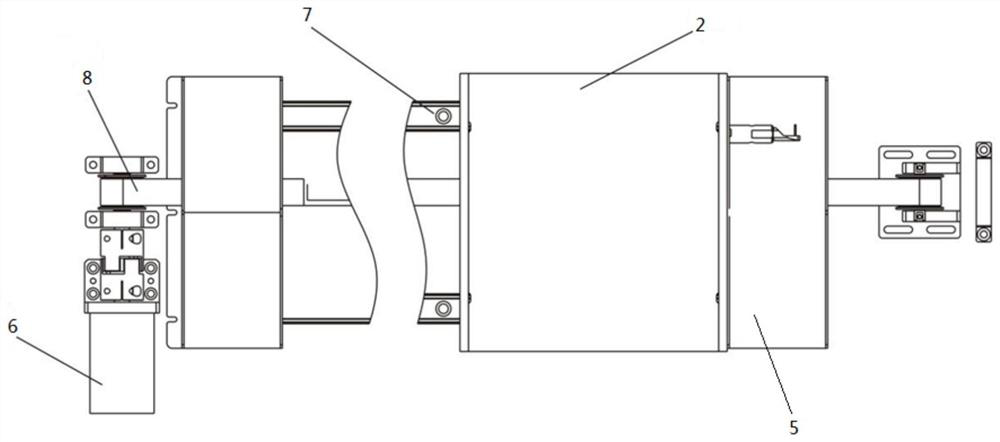

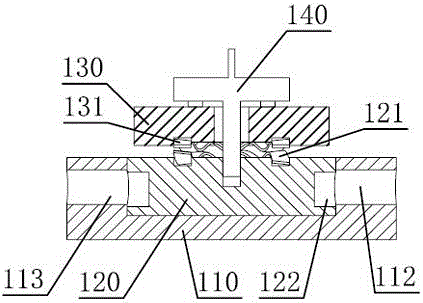

Tensioning device and method of prefabricated track plate

ActiveCN106079067APrecise control of tensionShorten the production cycleCeramic shaping apparatusPower unitEngineering

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +3

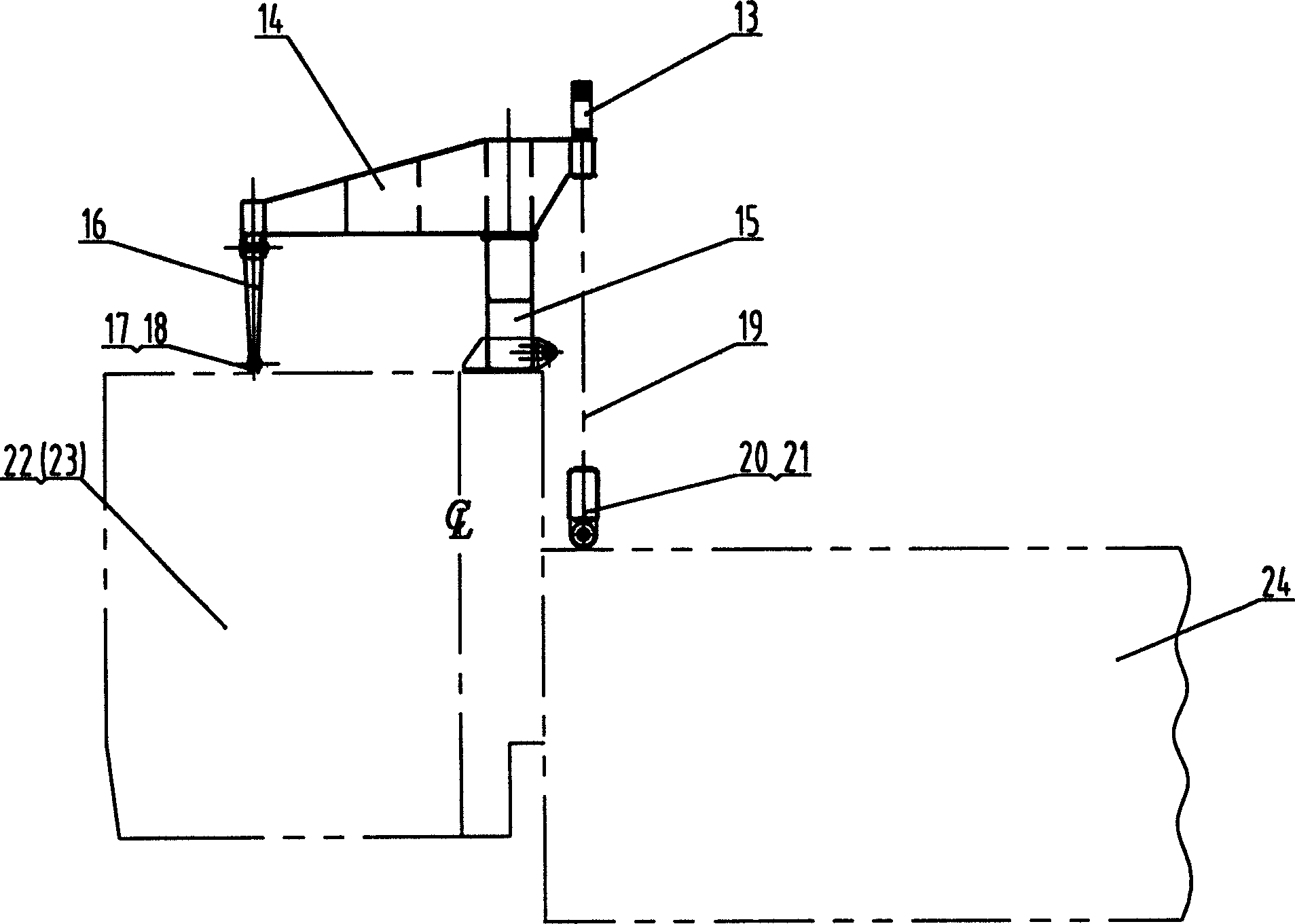

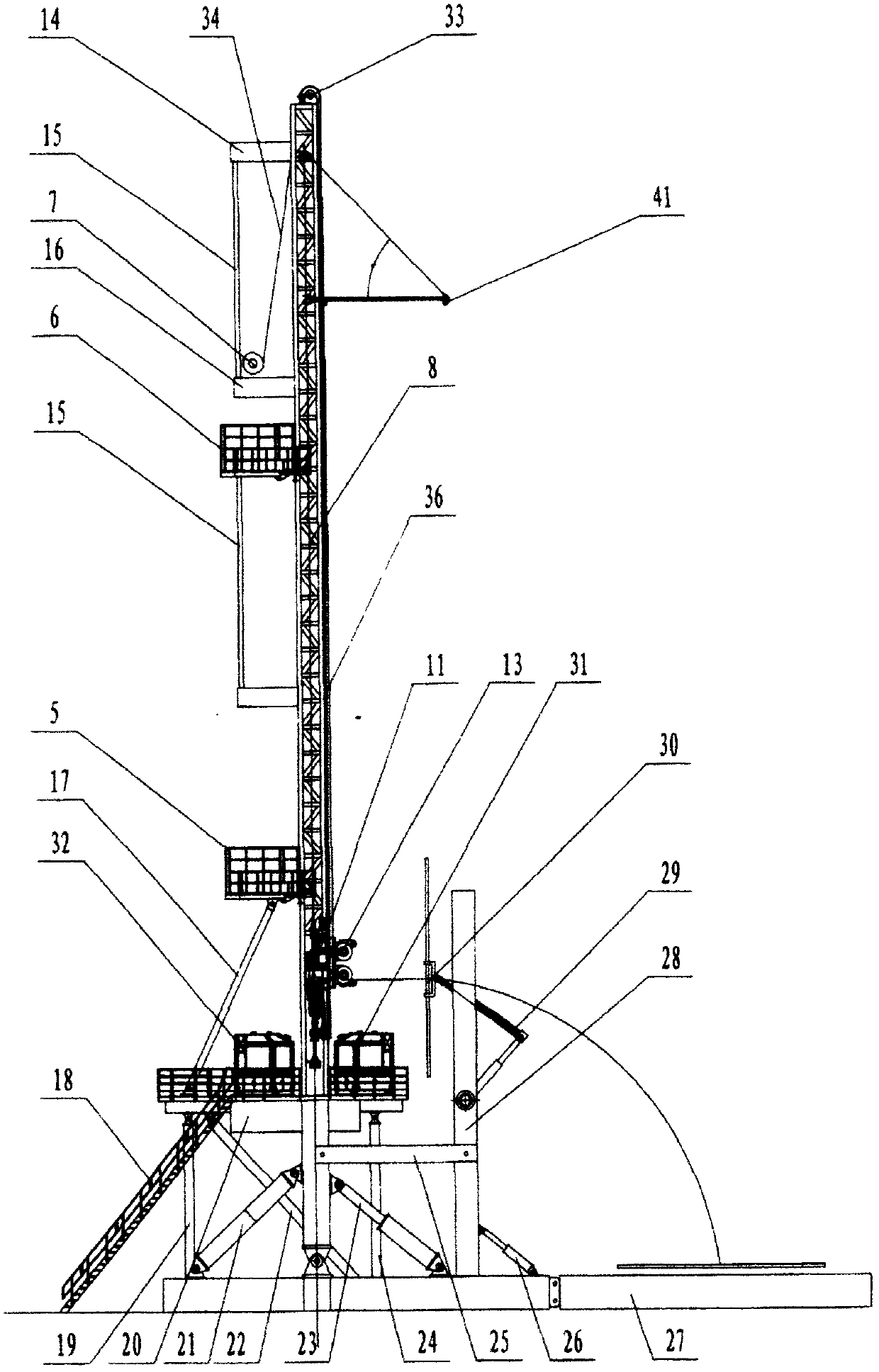

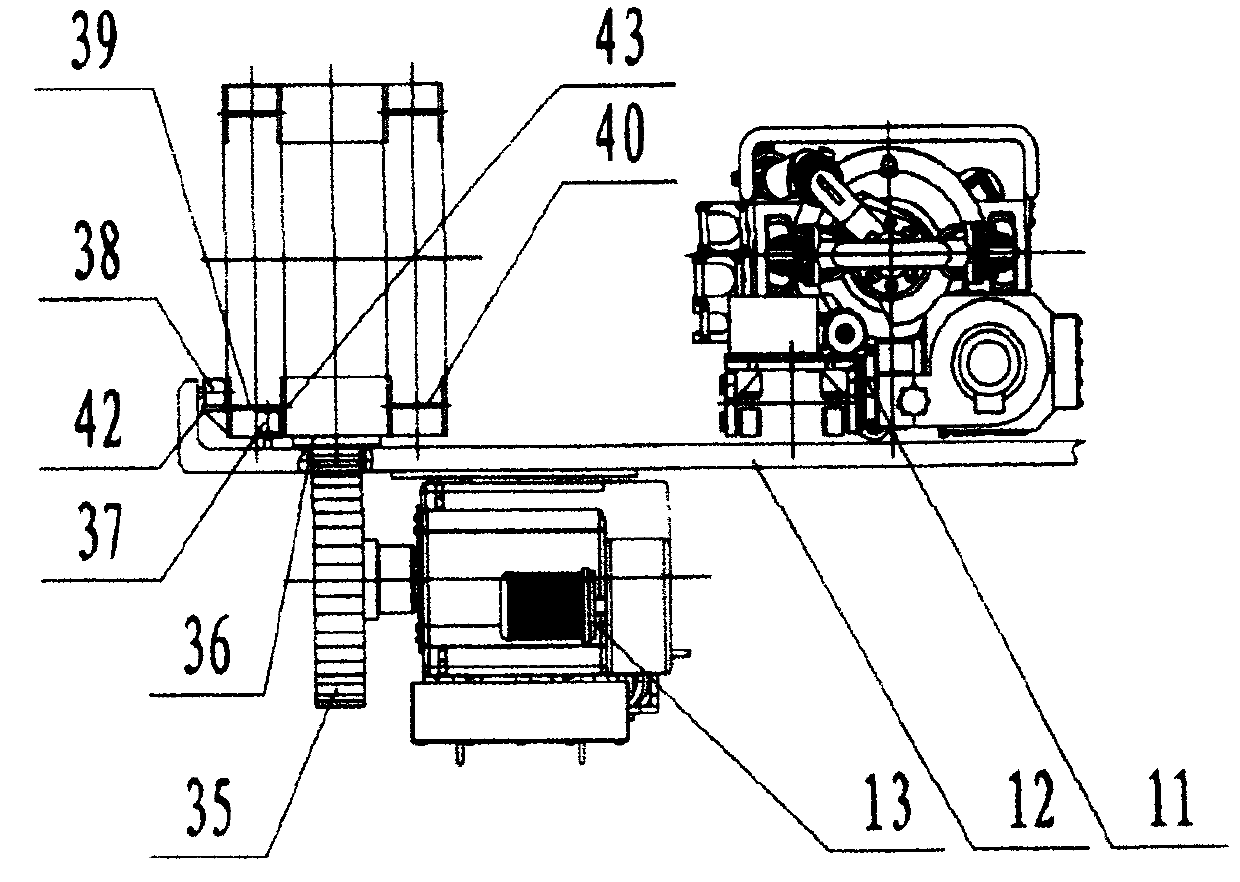

Gate-type double-tower gear-driven drilling machine

The invention relates to a gate-type double-tower gear-driven drilling machine. A headframe body assembled on a base comprises two parallel single-gate-post towers, a racking platform provided with a single drill rod and a racking platform provided with double drill rods are arranged in the middle of the headframe, a vertical rack track is arranged in the position of a side surface of a headframe, and a fast trip device comprises a pulley block arranged at the top of the headframe, a steel wire rope and a fast trip winch; a top drive of the drilling machine is arranged on a top drive pulley where a motor and a suspension device are mounted; the suspension device of the top drive pulley is connected with the steel wire rope of the fast trip device; an output shaft of the motor on the top drive pulley is meshed with the vertical rack track through a gear; and a drill rod moving device is mounted on the headframe or the base in a hinging manner. During working, the suspension can rapidly release the top drive under the drive of the trip winch, so that rapid conversion of well repairing, drilling and forcibly tripping operation of a tubular column is realized, and requirements of no-load / light-load rapid tripping operation when the drilling machine drills a deep well are met.

Owner:SHAANXI XINLONG PETROLEUM EQUIP

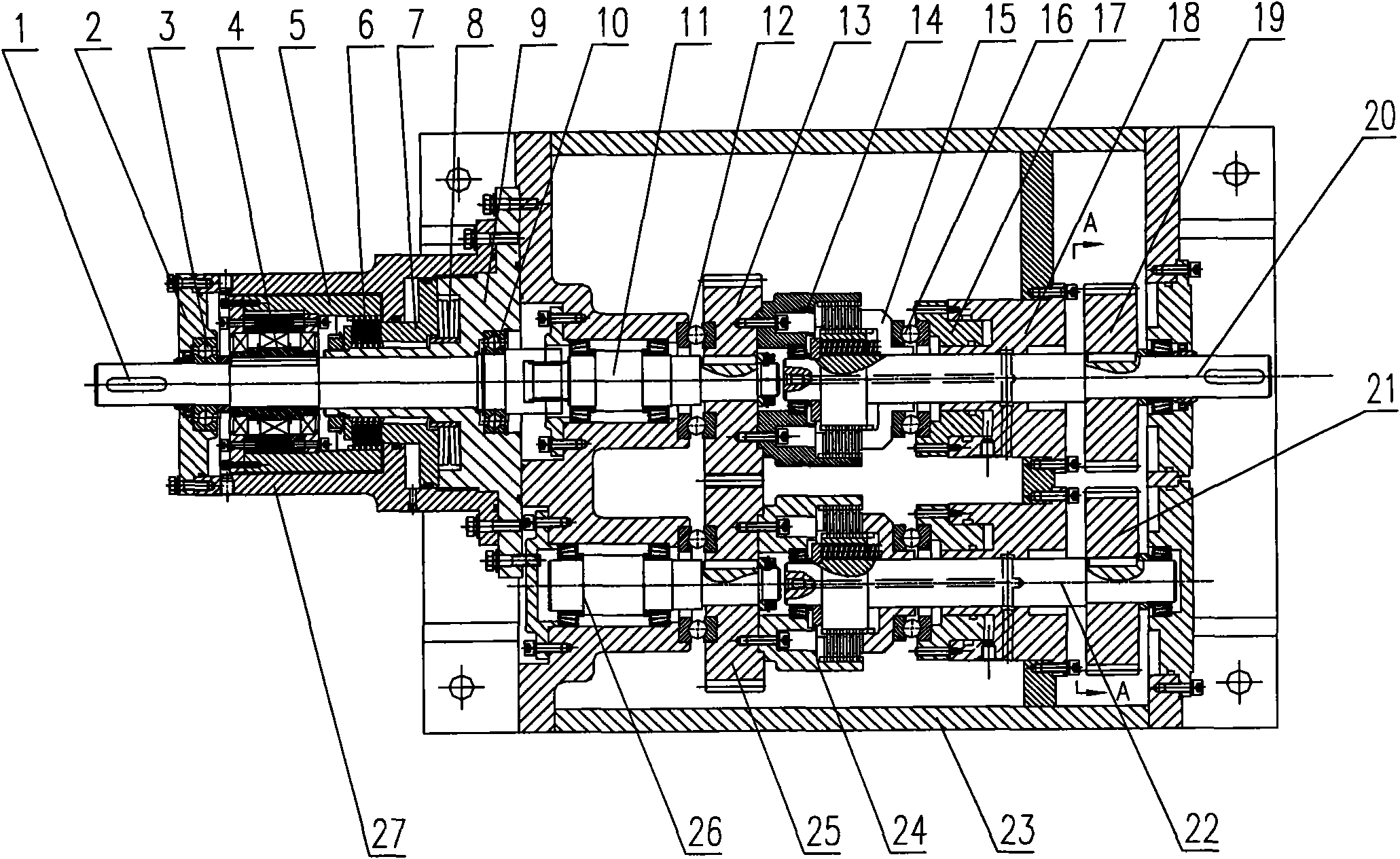

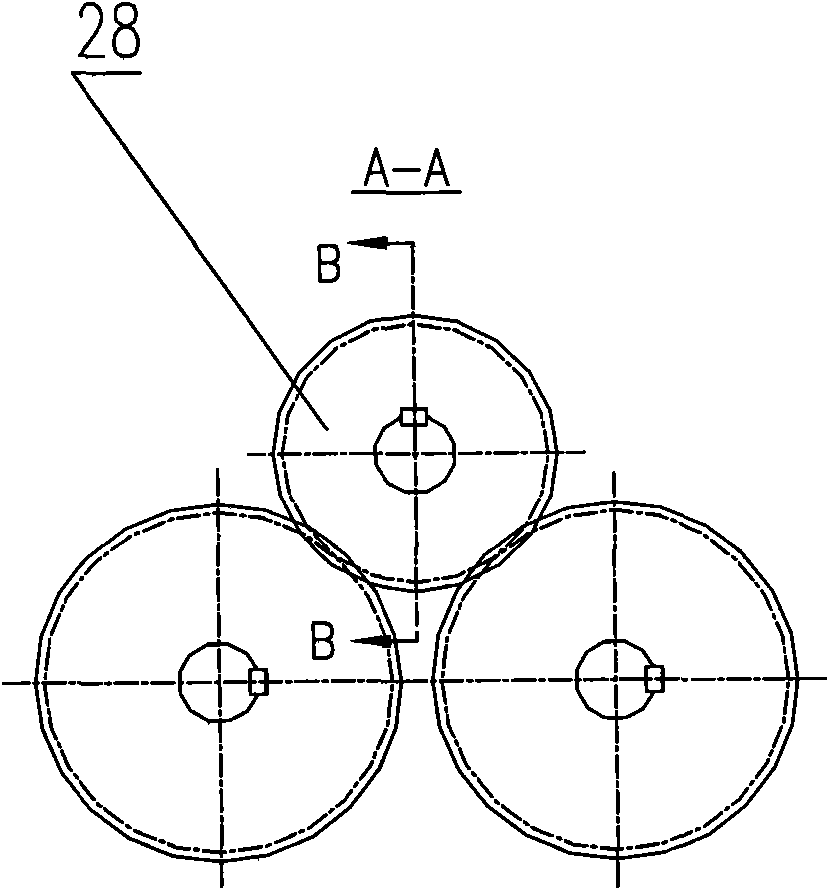

Tensioning winch transmission device of belt conveyer

InactiveCN101941580ARealize frequent switchingAvoid frequent switchingConveyorsToothed gearingsEngineeringWinch

The invention relates to a tensioning winch transmission device of a belt conveyer, which mainly comprises a box body, a main transmission mechanism, an auxiliary transmission mechanism and an output transmission mechanism which is arranged at the front end of the box body and connected with the main transmission mechanism, wherein the main transmission mechanism and the auxiliary transmission mechanism are arranged in the box body in parallel. In the invention, a gear pair comprising a main clutch, an auxiliary clutch and five gears is adopted to achieve the purpose that an input shaft of a winch rotates along one direction all the time while reeling off and rolling up so as follow the tensile force change of a conveyer belt and meet the requirement on the change of the conveyer belt within a larger range; dynamic braking can be directly carried out through a motor to limit the maximum reeling off speed so as to prevent safe accidents; and soft start during rolling up can be realized, thus impact force born by a steel wire rope and relevant components is reduced, and the service life of the components is prolonged. The device can be used for precisely controlling the tensioning force and is suitable for controlling the tensioning winch of the belt conveyer, particularly for a narrow space under a coal mine. The device has the advantages of simple structure, convenient maintenance, low manufacturing cost, strong generality and high reliability.

Owner:CHINA UNIV OF MINING & TECH +1

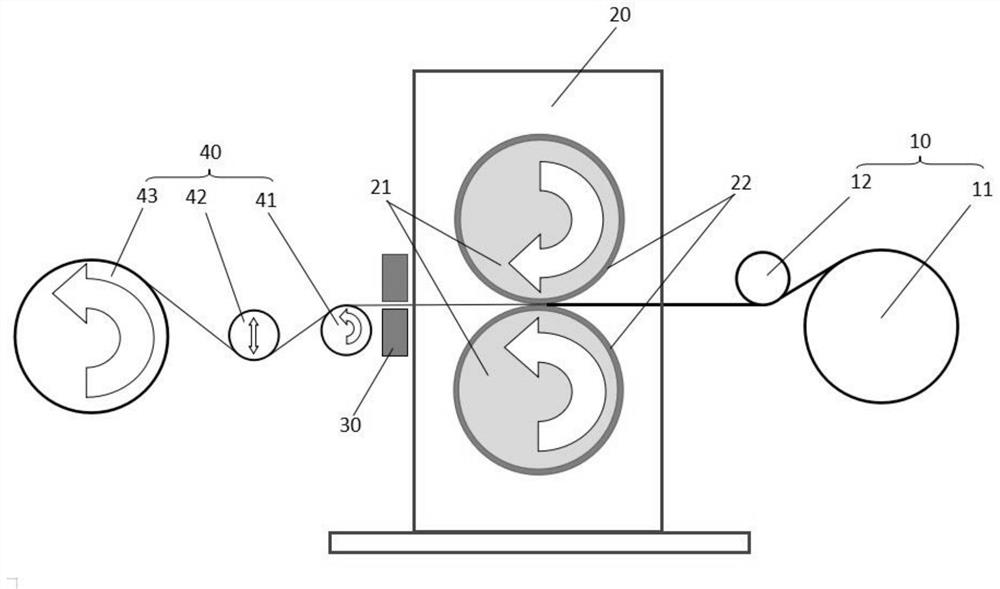

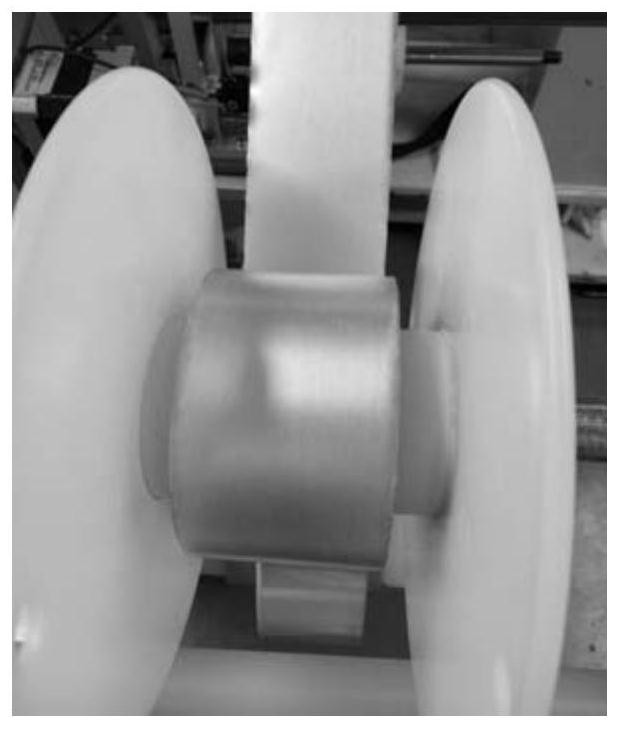

Ultrathin lithium foil and preparation method thereof

PendingCN111725496APrecise control of tensionPrecise Control of SpacingCell electrodesSecondary cellsChemistryComposite material

The invention provides an ultrathin lithium foil product and a preparation method thereof. The ultrathin lithium foil is a continuous and self-supporting strip-shaped foil with the lithium content of99.90%-99.99%. The thickness of the ultrathin lithium foil is 10-20 [mu] m, and the width of the ultrathin lithium foil is 10-500 mm. The surface of the ultrathin lithium foil is bright in color and is silvery white; the surface of the lithium foil is smooth, and holes and damage which can be visually observed do not exist; and the lithium foil has neat edges and no defects.

Owner:CHINA ENERGY LITHIUM

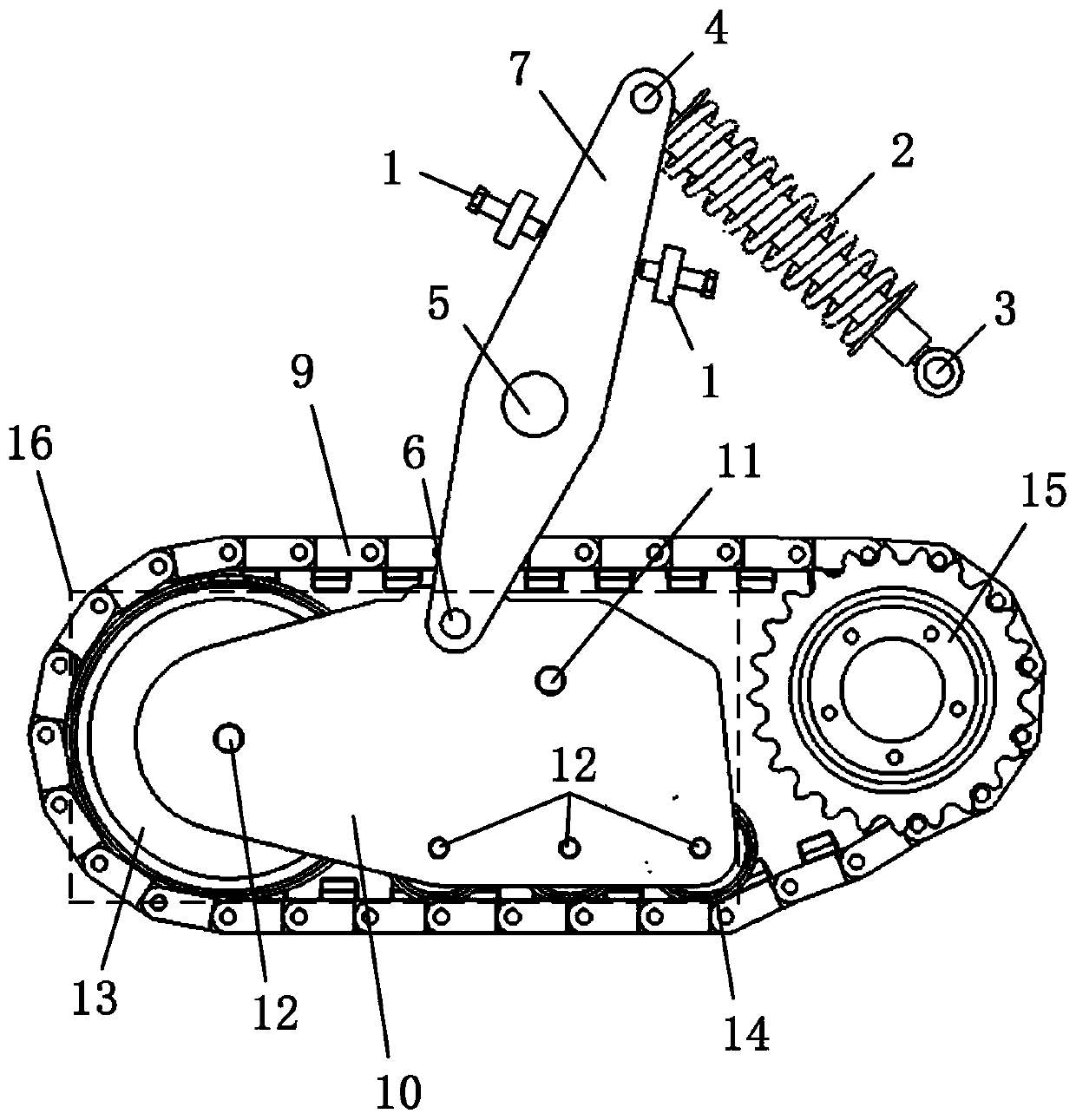

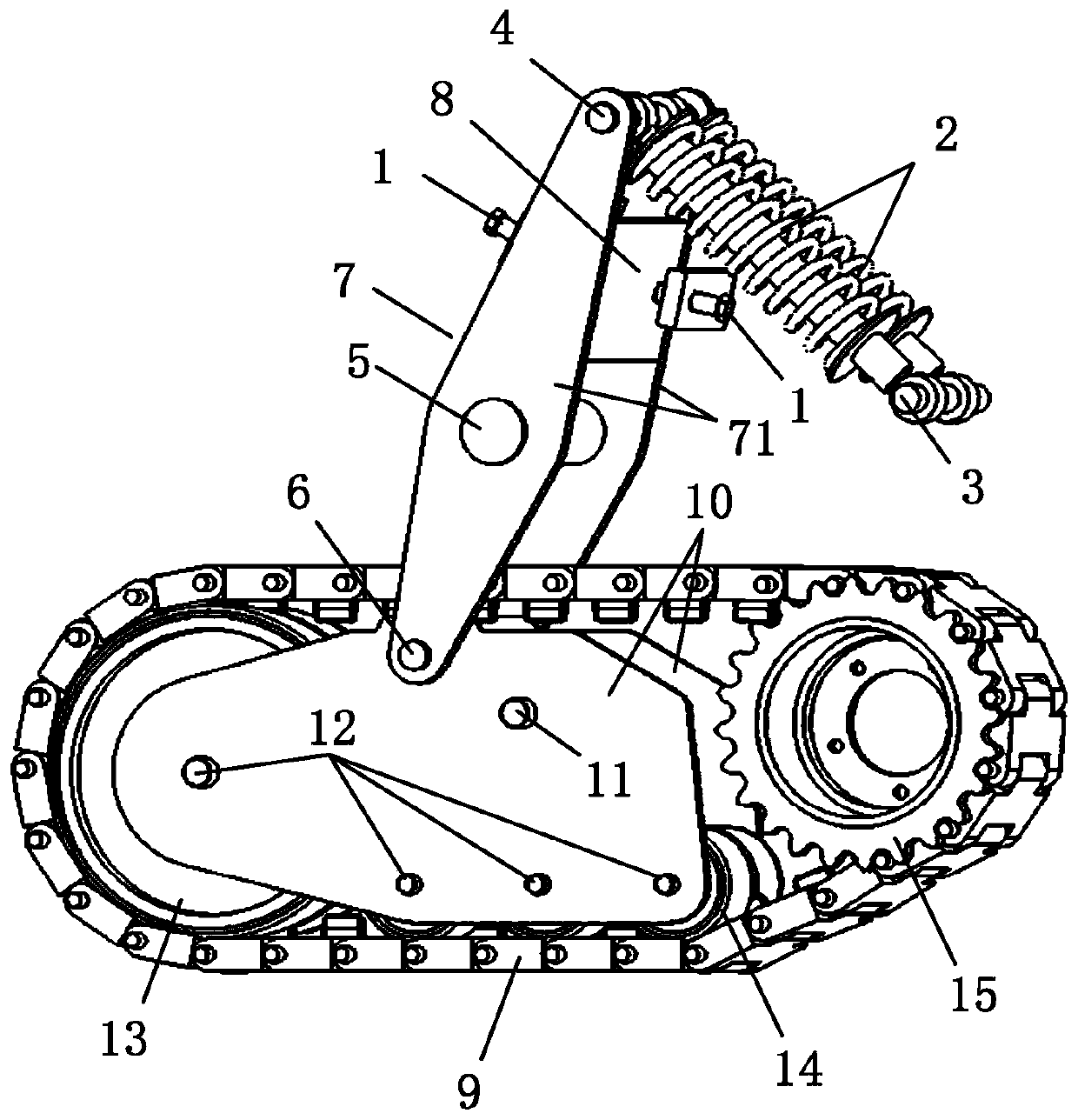

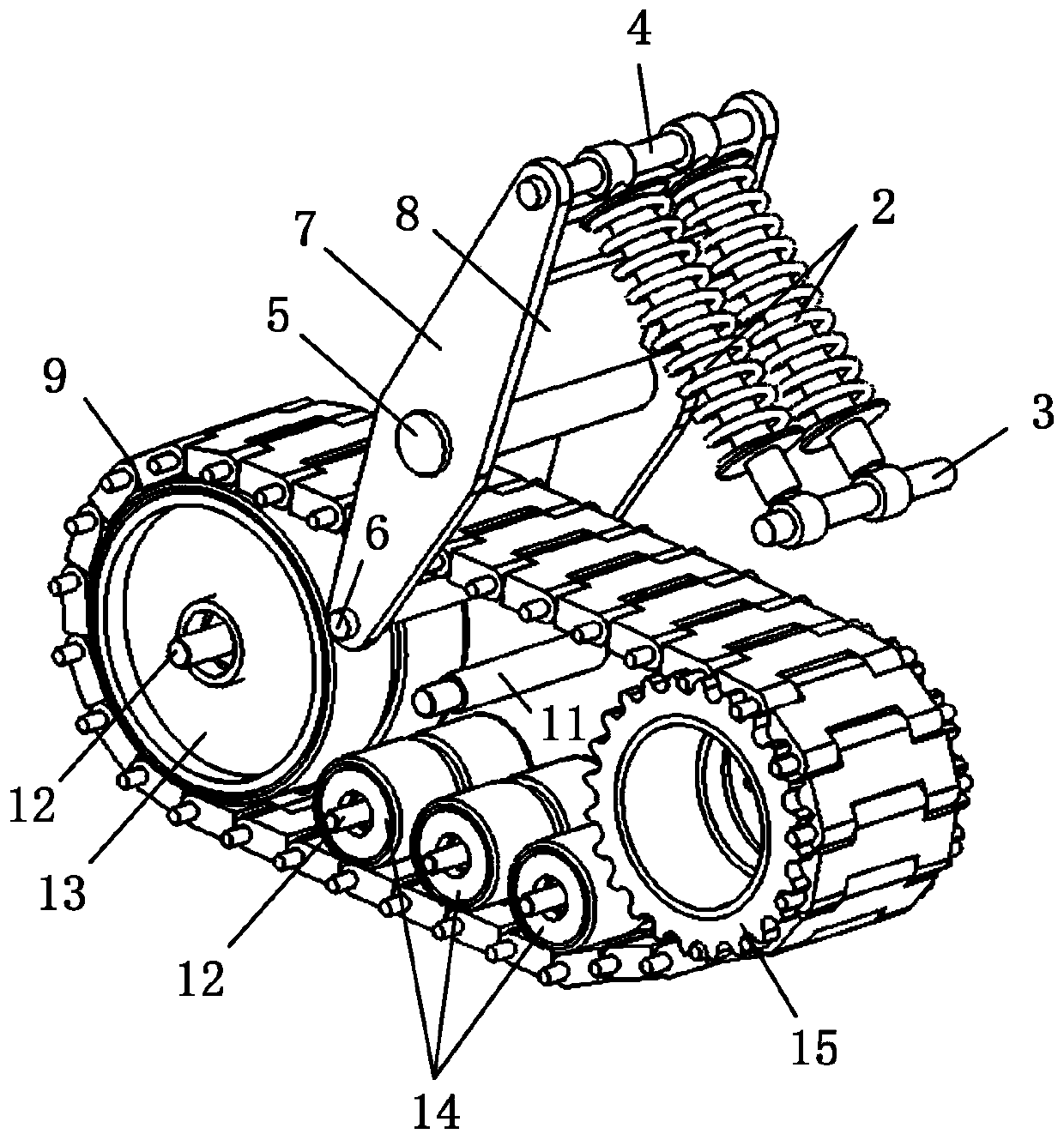

Crawler-type swing arm suspension type walking mechanism and crawler vehicle

The invention discloses a crawler-type swing arm suspension type walking mechanism and a crawler vehicle. The walking mechanism comprises a spring damping component, one end of the spring damping component is rotationally connected with a first connecting shaft fixed on a vehicle body, and the other end of the spring damping component is rotationally connected with one end of a swing arm through afirst rotating shaft, the other end of the swing arm is rotationally connected with two gear train fixing plates through a second rotating shaft, a second connecting shaft is rotationally installed in the middle of the swing arm, the second connecting shaft is fixed on the vehicle body, the two sides of the swing arm are respectively provided with a tensioning adjuster, the two gear train fixingplates are fixedly connected through a fixed shaft, an idler wheel and bogie wheels are installed between the two gear train fixing plates through a wheel shaft, the idler wheel is connected with a driving wheel through a crawler ring, and the driving wheel is meshed with the crawler ring and is connected with a decelerator fixed on the vehicle body. The crawler-type swing arm suspension type walking mechanism in the invention is simple and compact in structure, the crawler ring is convenient for tensioning adjustment and easy to implement, and the crawler-type swing arm suspension type walking mechanism is good in tensioning and suspension vibration damping performance and capable of being flexibly arranged on the vehicle body.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

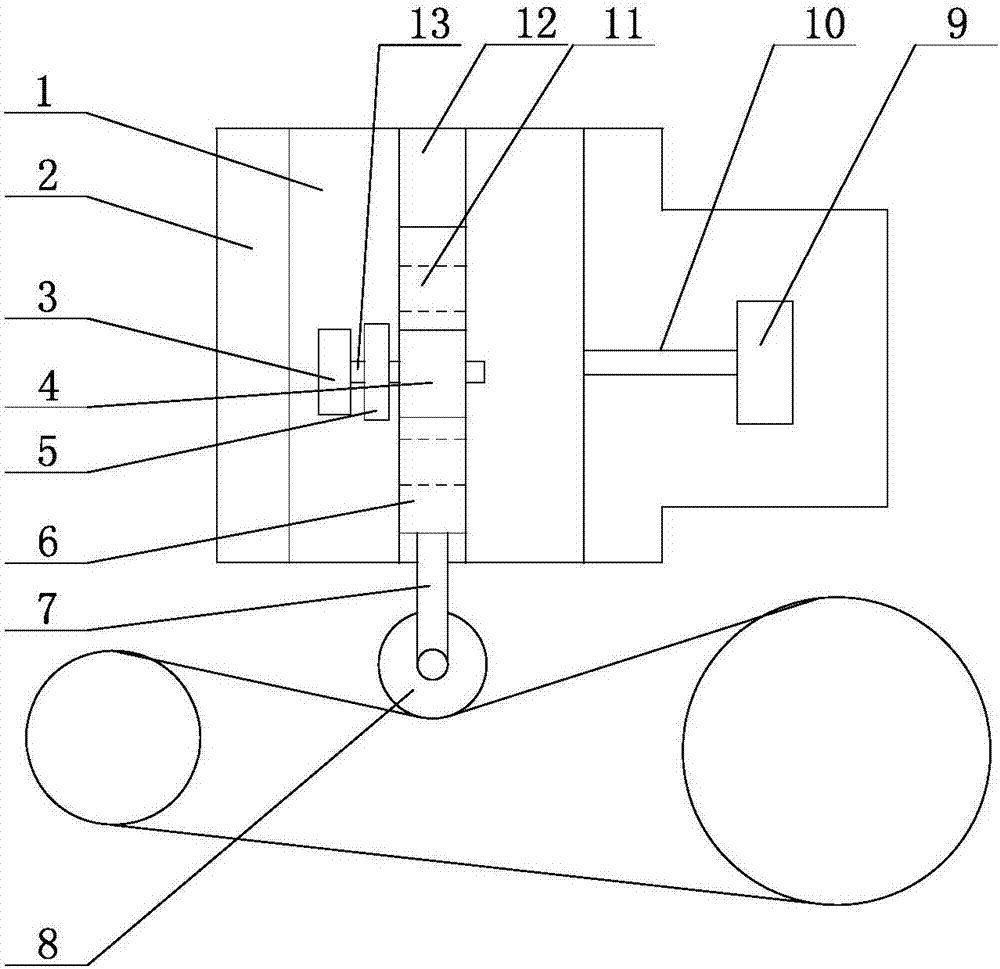

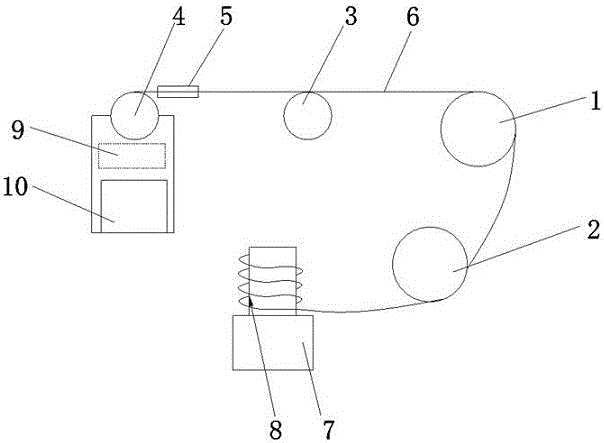

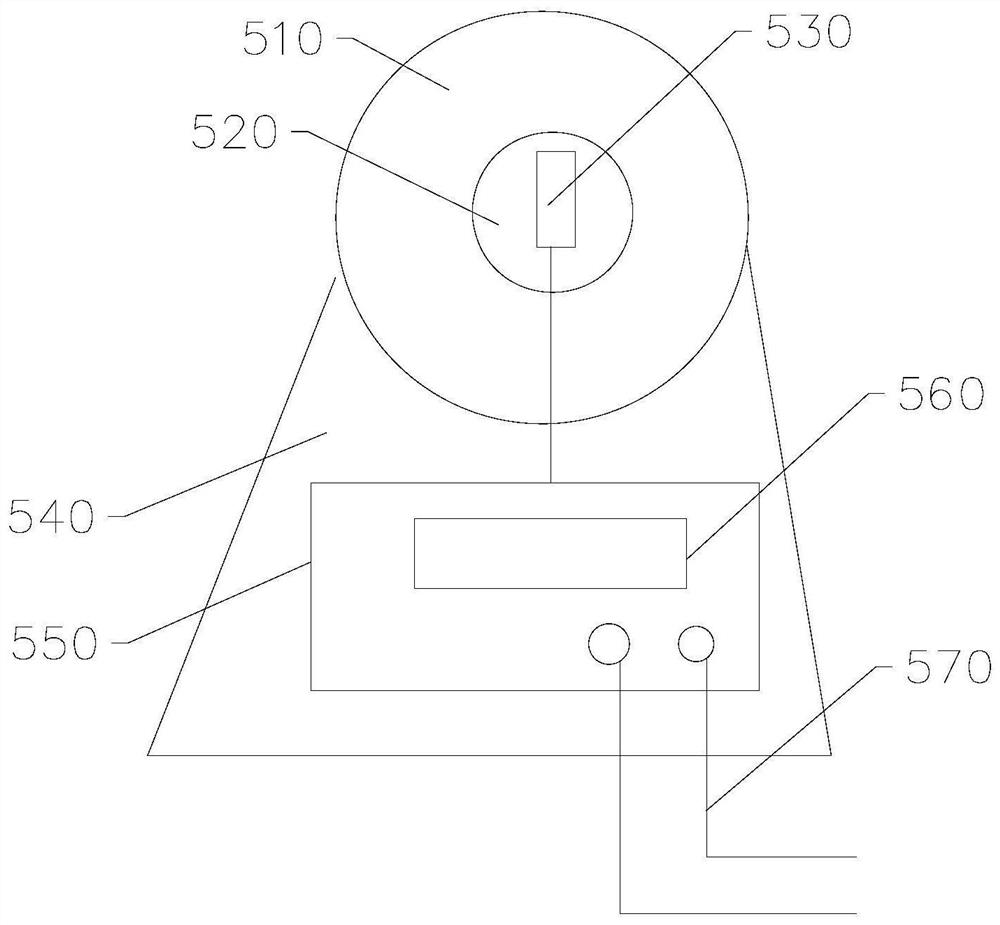

Tension control system for optical cable laying

InactiveCN105929514APrecise control of tensionAvoid damageOptical fibre/cable installationControl systemForce sensor

The invention discloses a tension control system for optical cable laying. The tension control system includes a first traction wheel, a second traction wheel, a tensioning wheel, a tension machine and a tension sensor; the first traction wheel and the second traction wheel are fixed; the second traction wheel is arranged below the first traction wheel; the tensioning wheel is arranged at the front end of the first traction wheel; the center of the tension wheel and the center of the first traction wheel are on the same straight line; one end of an optical cable is fixed in a guide groove of a fixing pile; the other end of the optical cable is wound on the peripheries of the first traction wheel, the second traction wheel and the tensioning wheel and is connected with the tension machine; the tension sensor is fixed to one end of the optical cable which is adjacent to the tension machine; the tension machine is provided with a servo motor and a controller; and the controller is connected with the servo motor and the tension sensor. The tension control system of the invention is simple in principle. With the tension control system adopted, precise control on the tension of the optical cable can be realized, the tension can be prevented from becoming too large, so that the optical cable can be protected from being damaged, and the efficiency of optical cable laying can be improved.

Owner:HENAN HONGJUN COMM ENG CO LTD

Suture equipment for insert and suture method of equipment

ActiveCN109394281APrecise suture positionImprove sewing efficiencySuture equipmentsSewing apparatusBiomedical engineeringReciprocating motion

The invention discloses suture equipment for an insert. The equipment comprises a dual-head needle, a control component, a first machine needle driving assembly, a second machine needle driving assembly and a conveying assembly; the first machine needle driving assembly, the second machine needle driving assembly, the conveying assembly and the control component are in communication connection, and the control component is used for controlling motion of the first machine needle driving assembly, the second machine needle driving assembly and the conveying assembly; the dual-head needle is provided with a needle hole for a suture thread to penetrate through; the first machine needle driving assembly and the second machine needle driving assembly are arranged at the two opposite sides of thedual-head needle respectively, a suture gap for a to-be-sutured part to pass through is formed between the first machine needle driving assembly and the second machine needle driving assembly, and the first machine needle driving assembly and the second machine needle driving assembly can clamp and release the dual-head needle and drive the dual-head needle to reciprocate along a first path so that the to-be-sutured part can be sutured. According to the suture equipment, the labor cost can be reduced, and the production efficiency can be improved.

Owner:MICROPORT SINICA CO LTD

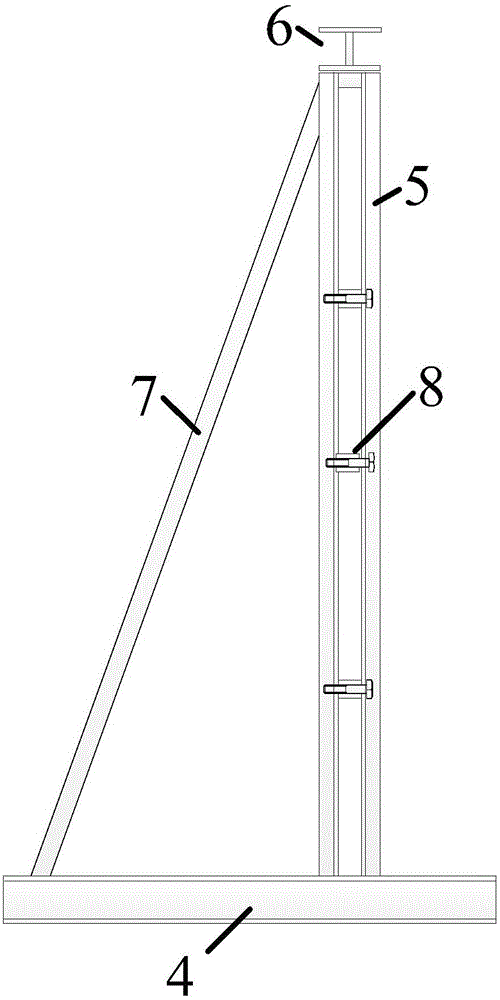

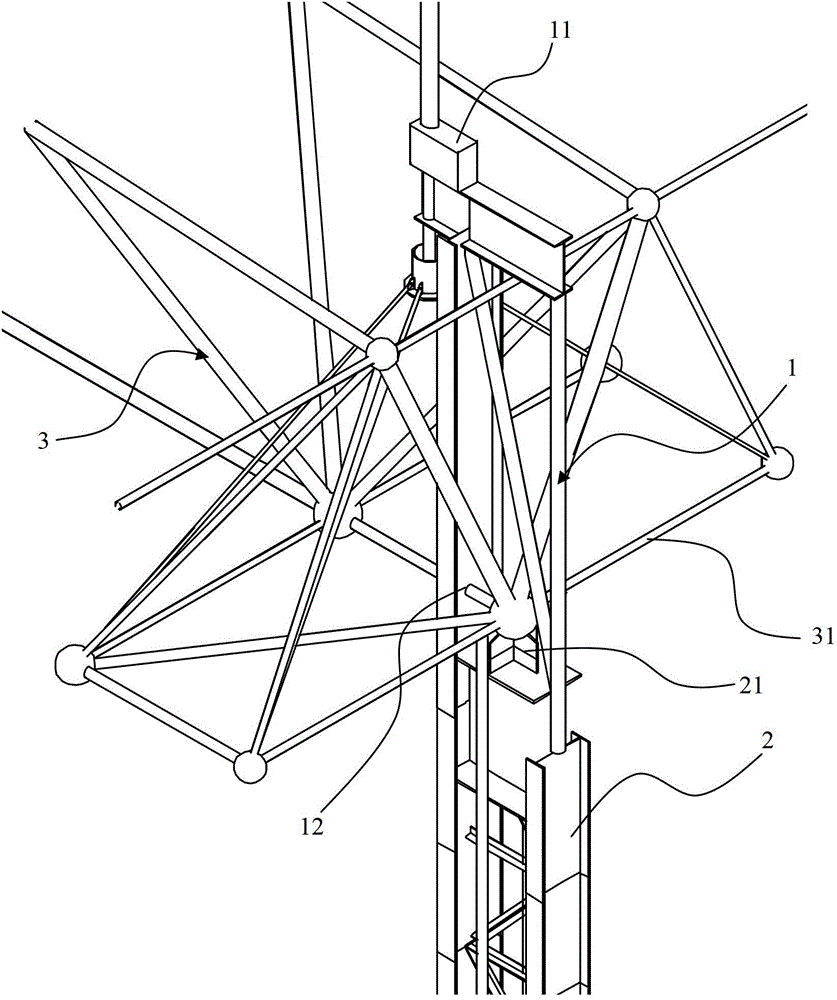

Unloading method of net frame lifting frames

ActiveCN102864938APrecise control of tensionAvoid overstressingBuilding material handlingPull forceEngineering

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Non-contact flatness measurement model solving device

ActiveCN104655091AMeet the requirements of high surface cleanlinessGuaranteed accuracyMeasurement devicesModel descriptionEngineering

The invention discloses a non-contact flatness measurement model solving device with simple and diversified measurement ways. The non-contact flatness measurement model solving device comprises a rectangular operating platform, wherein a supporting seat is arranged below the operating platform, and side plates are fixedly arranged on the two sides of the operating platform; a pneumatic vibration-guiding suction disc and a displacement sensor are arranged on the operating platform, the pneumatic vibration-guiding suction disc is connected with a pneumatic distributor and a control device, and the pneumatic distributor is connected with a gas pressure inlet through a high-frequency valve. Through the vibration guiding of the pneumatic vibration-guiding suction disc on strips, the displacement sensor outputs strip vibration data, the data is processed through software, and a conclusion is drawn. The device can be applied to online flatness measurement and can also be used for fault diagnosis of flatness measurement. The operation of the device is non-contact, so that requirements of the static measurement model description of the strips, which has the characteristics of being high in surface cleanliness and the like, are met.

Owner:苏州珂锐铁电气科技有限公司

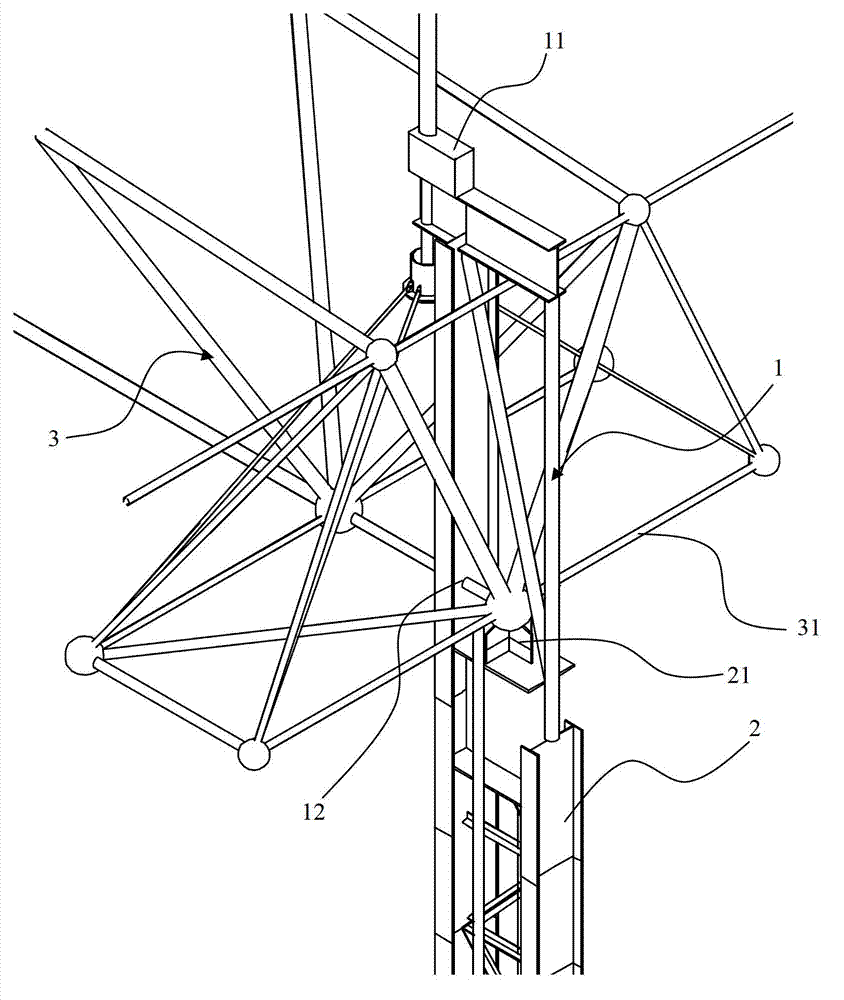

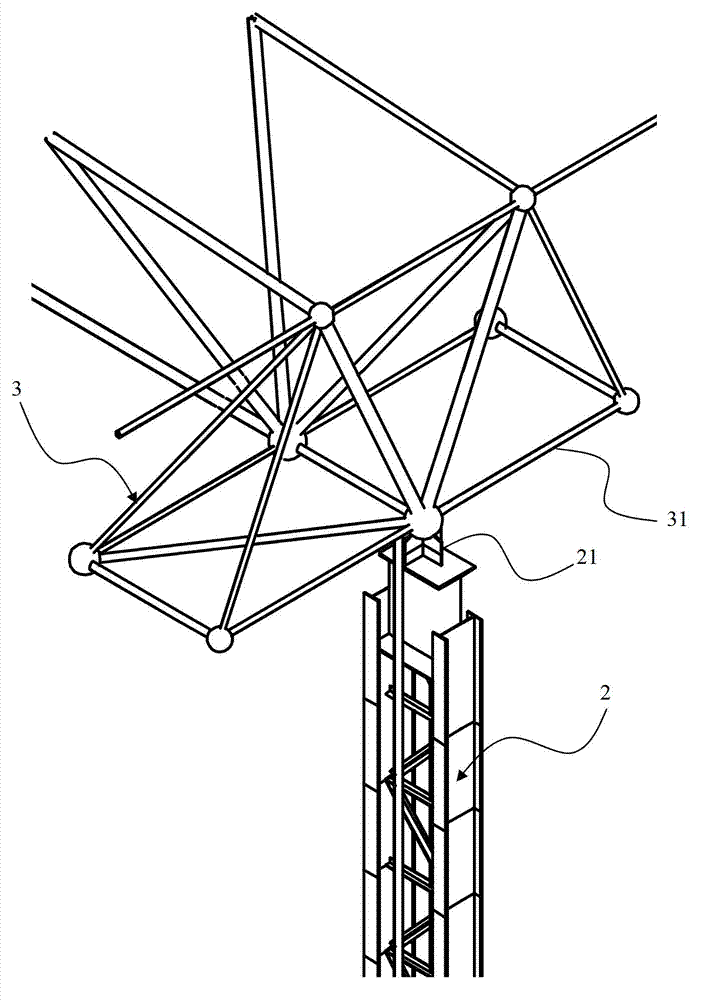

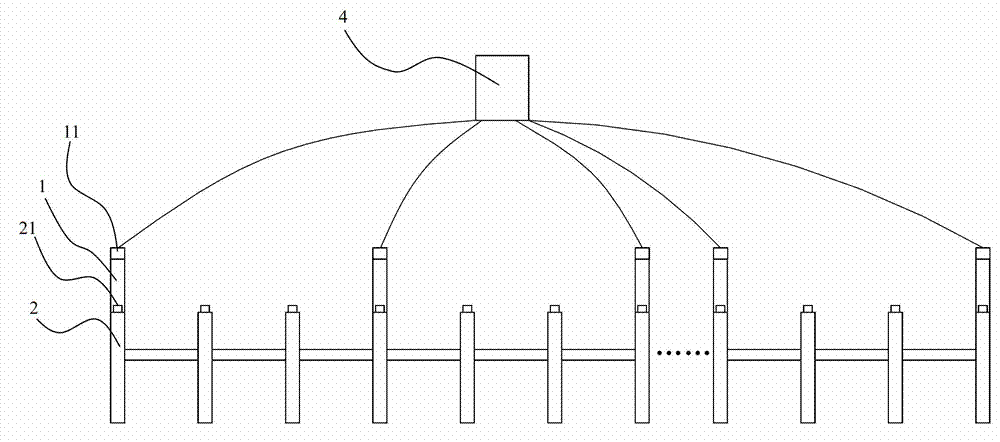

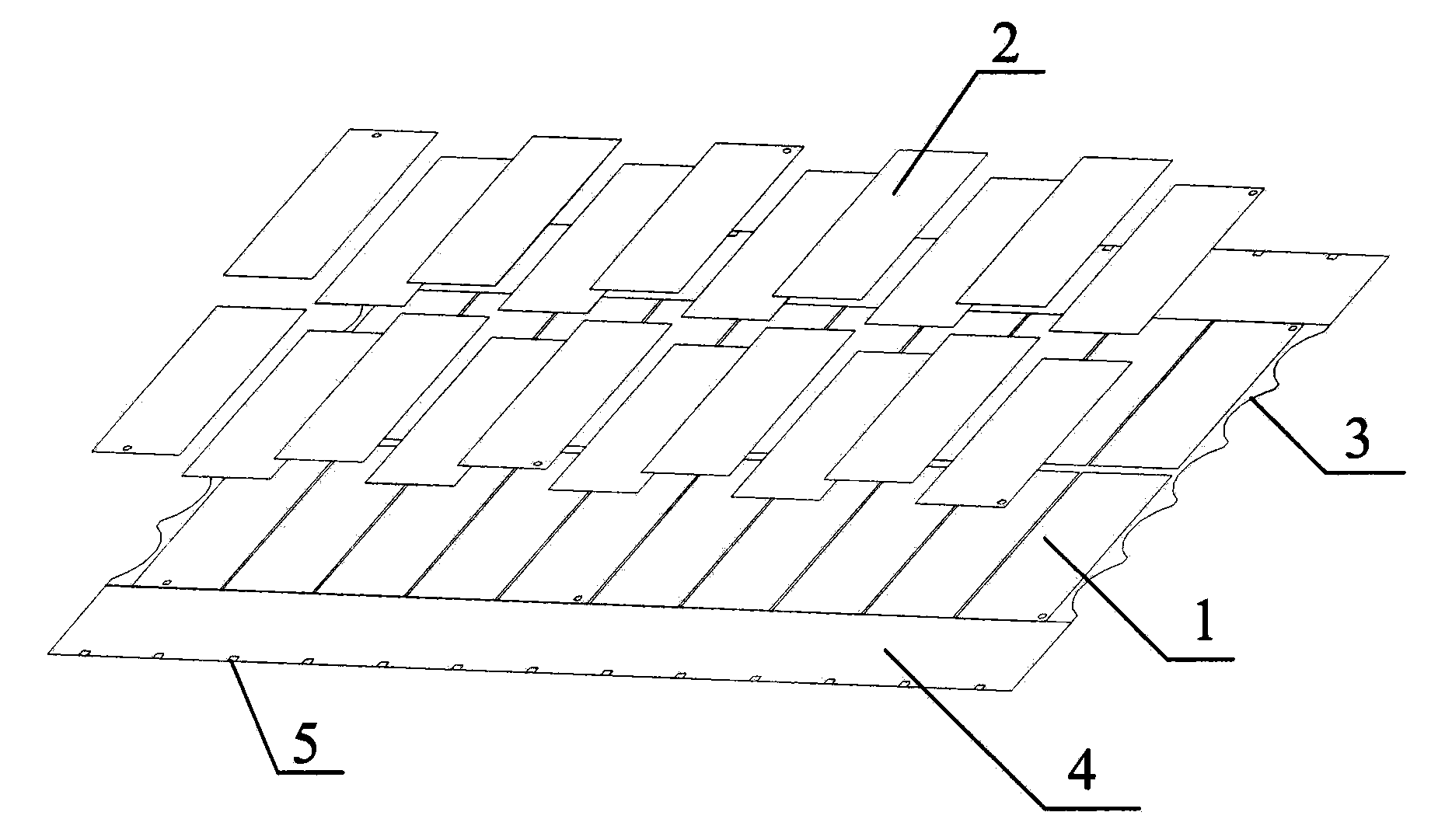

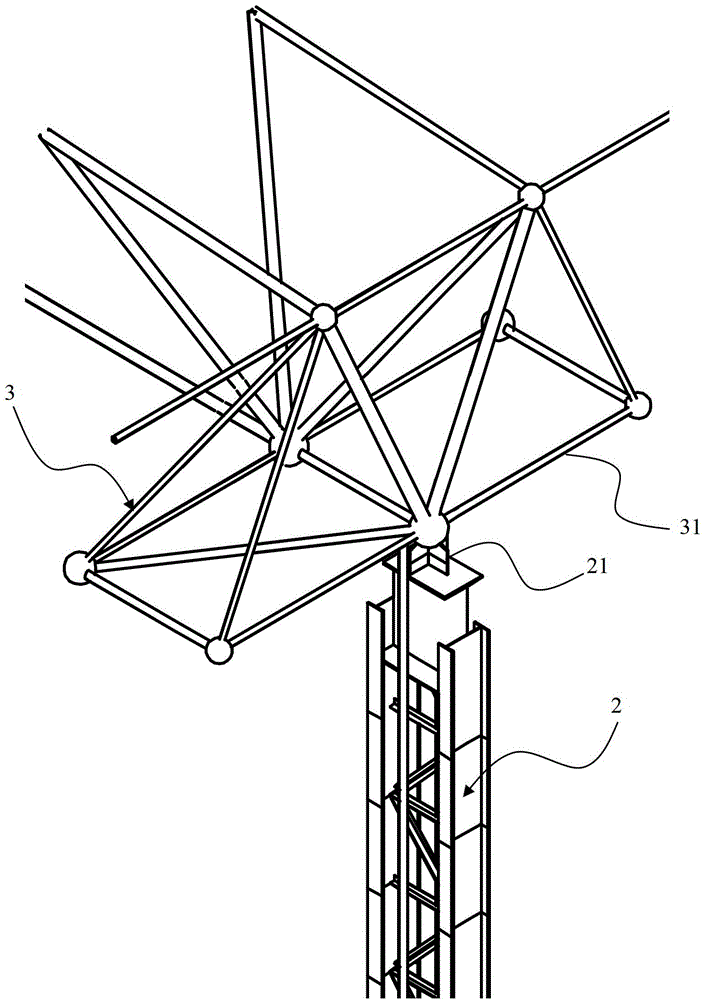

Method for preparing pre-tension membrane structure antenna

ActiveCN102593576BSolve size-constrained challengesGuaranteed fixed spacing requirementsAntenna arraysAntenna supports/mountingsNomex honeycombMembrane surface

The invention relates to a method for preparing a pre-tension membrane structure antenna. The method comprises the following steps: designing a membrane surface into a base membrane and electric membranes, splicing the base membrane and forming the electric membranes; marking out a bottom membrane according to a designed paste range, pasting the electric membranes; processing catenaries, splicing auxiliary strengthening plates, positioning the membrane surface by utilizing installation holes of a support framework of the membrane antenna and placing the first membrane surface on a corresponding position of the support framework; reversely loading pretightening force on the long side of the membrane surface by utilizing auxiliary loaded ropes and the support of the support framework, pre-tensioning tension ropes by an adjustment device and adjusting the tension ropes to designed positions for splicing and fixing; and installing a dielectric Kevlar / Nomex honeycomb panel so as to finally realize an antenna array surface. In the method, a phased-array antenna array surface is realized through a membrane structure; the weight of a traditional phased-array antenna structure is lightened; and the method provided by the invention has the characteristics that the pre-tension membrane structure antenna is capable of being continuous loaded; the membrane tension can be accurately controlled, the operation is convenient, a special membrane tying tool is not needed, and the like.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Weaving machine

The invention discloses a weaving machine and belongs to the technical field of textile machinery. The technical points of the weaving machine is that the weaving machine comprises a transmission mechanism, a weaving member and a positioning mechanism, wherein the transmission mechanism can move the relative position of a bearing seat by adjusting the relative position between a movement plate and a guide rail plate to further control the belt tension, and then a positioning bolt is tightly screwed and fixed to facilitate the adjustment and the accurate control of the belt tension. The weaving member is connected and matched with a transverse gear through a perpendicular gear, and accordingly the mechanical transmission efficiency is high. The positioning mechanism is connected with the weaving member through a belt, and the weaving member is connected with the transmission mechanism so as to save power and cost and improve the efficiency.

Owner:钱达

Wire tightening device for low-voltage bundled wire installation

ActiveCN112909829APrevent fallingHigh clamping reliabilityElectronic waste recyclingApparatus for overhead lines/cablesElectric machineDrive motor

The invention provides a wire tightening device for low-voltage bundled wire installation, which comprises a bracket, a base, a tensioning frame, a wire clamping device, a tension detection device, a pulley block, a non-return device, a winding wheel, a synchronous belt, a driving motor, a moving wheel, a fixed hand wheel, a moving clamping jaw, a fixed clamping jaw and a lead screw, and is characterized in that the wire clamping device comprises a frame plate and a wire pressing assembly; the wire pressing assembly comprises four wire pressing cams, a connecting plate and a pressing handle, every two of the four wire pressing cams are divided into two sets of wire pressing cams, the two sets of wire pressing cams comprise the first set of wire pressing cams and the second set of wire pressing cams, the first set of wire pressing cams and the second set of wire pressing cams are arranged in a front-back spaced mode and the frame plate comprises a bottom frame plate and a side frame plate; the wire pressing assembly is arranged on the side frame plate, and after the side frame plate and the bottom frame plate are installed in place, the four wire pressing cams press and fix the bundled wires placed on the bottom frame plate, so that the wire tightening effect and the operation efficiency of the wire tightening device can be greatly improved, the operation time of operators is shortened, and the labor intensity of the operators is reduced.

Owner:STATE GRID ZHEJIANG TONGLU POWER SUPPLY +1

Band steel traction connection structure and band penetration method for continuous band steel unit

InactiveCN104209350AThe ring structure is firmAvoid excessive concentrationFlexible work arrangmentsMetal rolling arrangementsTension controlMaterials science

The invention discloses a band steel traction connection structure and a band penetration method for a continuous band steel unit, and particularly relates to the field of band steel production. The band steel traction connection structure which is firm in connection, is capable of reducing the band breaking frequency and is provided by the invention comprises a band steel end part, a band steel traction head, a pull ring and a traction band, wherein one end of the band steel traction head and the band steel end part are of an integrated structure, and the other end of the band steel traction head is riveted on the band steel end part, so that an annular structure is firmer. The band penetration method for the continuous band steel unit, which is provided by the invention, comprises the following steps: a, lowering a loop trolley to a zero position; b, winding the traction band around each roller group; c, fixedly connecting the band steel traction connection structure with one end of band steel; d, tensioning a loop; e, filling the loop with the traction band; f, performing band penetration operation. The tension of the traction band is accurately controlled through automatic tension control equipment, so that breaking of the traction band due to the fact that a certain part is over-tensioned is avoided.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

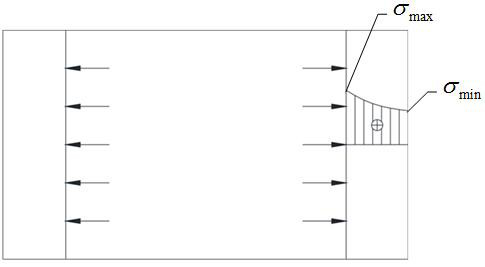

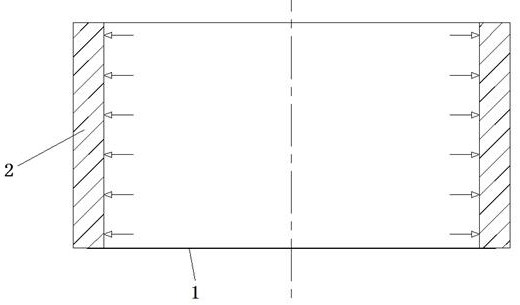

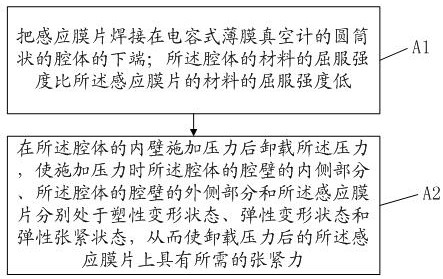

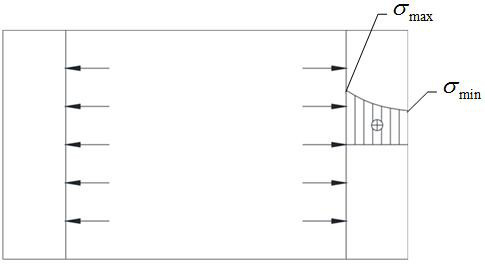

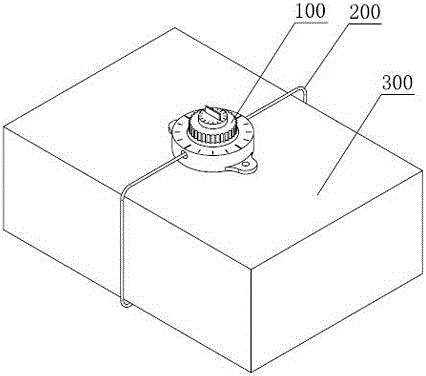

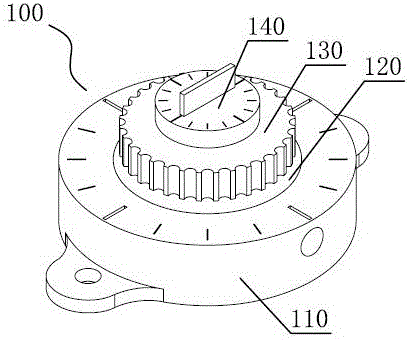

Method for controlling post-welding tensile force of induction diaphragm of capacitive film vacuum gauge

ActiveCN113739989AProcess controllableReliable workmanshipVacuum gaugesMachiningUltimate tensile strength

The invention belongs to the technical field of machining and discloses a method for controlling post-welding tensile force of a induction diaphragm of a capacitive film vacuum gauge. The method comprises the following steps that an induction diaphragm is welding at a lower end of a cylindrical cavity of the capacitive film vacuum gauge; the yield strength of the material of the cavity is lower than that of the material of the induction diaphragm; after pressure is applied to the inner wall of the cavity, the pressure is unloaded, so the inner side part of the cavity wall of the cavity, the outer side part of the cavity wall of the cavity and the induction diaphragm are respectively in a plastic deformation state, an elastic deformation state and an elastic tensioning state when the pressure is applied, and the induction diaphragm after the pressure is unloaded has required tensioning force; the post-welding tensile force control method for the induction diaphragm of the capacitive film vacuum gauge is beneficial to realizing accurate control on the tensile force after the induction diaphragm is welded.

Owner:JIHUA LAB

Dynamic and real-time monitoring method of prestressed tendon tension in concrete bridges and special prestressed construction system

ActiveCN105603876BEnsure construction safetyPrecise control of tensionBridge erection/assemblyApparatus for force/torque/work measurementHuman–machine interfacePre stress

The invention belongs to bridge construction, and particularly relates to dynamic real-time monitoring method for concrete bridge prestressed tendon tensioning force and a special prestress construction system. The dynamic real-time monitoring method for the concrete bridge prestressed tendon tensioning force includes the steps of initializing and real-time dynamic control loading. The prestress construction system comprises at least one tensioning device, and each tensioning device comprises a hydraulic station, a reversing valve bank, a jack, an A / D data collecting module, a PLC, a central processing unit, a human-computer interface, a direct force measuring device, a hydraulic force measuring device, a prestressed tendon elongation measuring device, a friction resistance test device and a security alarm device. The double-control requirement, difficult to met in the prior art, for taking stress control as the principle thing and an elongation value as a checking item is met, the dynamic real-time monitoring method has the advantages that construction quality and safety can be effectively ensured, and problems found in the tensioning process can be solved in time.

Owner:CHINA RAILWAYS CORPORATION +3

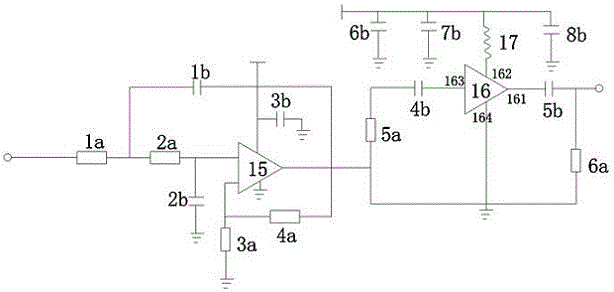

Wide lead belt production line continuous rolling synchronous control system

ActiveCN103056170AAvoid cumulative situationsAvoid being stretched or even brokenTension/compression control deviceElectric machineryProcess engineering

The invention discloses a wide lead belt production line continuous rolling synchronous control system which comprises motors, a plurality of roughing mills and a finishing mill arranged behind the last roughing mill. The wide lead belt production line continuous rolling synchronous control system further comprises a programmable logic controller (PLC) control system and needle type microswitches, each motor controls one roughing mill or one finishing mill singly, all motors are connected to the PLC control system, the needle type microswitches are arranged on the roughing mills except the last roughing mill and used for detecting whether lead belt accumulation exists between the roughing mills, and results are fed back to the PLC control system. Through a buffer mechanism composed of an angle sensor, a supporting plate and a cylinder, rolling speed of the roughing mills or the finishing roll is controlled by matching with torque monitoring current so that tension of a lead belt can be controlled within an acceptable range accurately, accumulative error of the lead belt can be self-repaired and adjusted, and adjustment can be performed rapidly under different conditions.

Owner:JIANGSU SANHUAN IND HLDG CO LTD

Method for controlling FBG wavelength based on double-grating structure

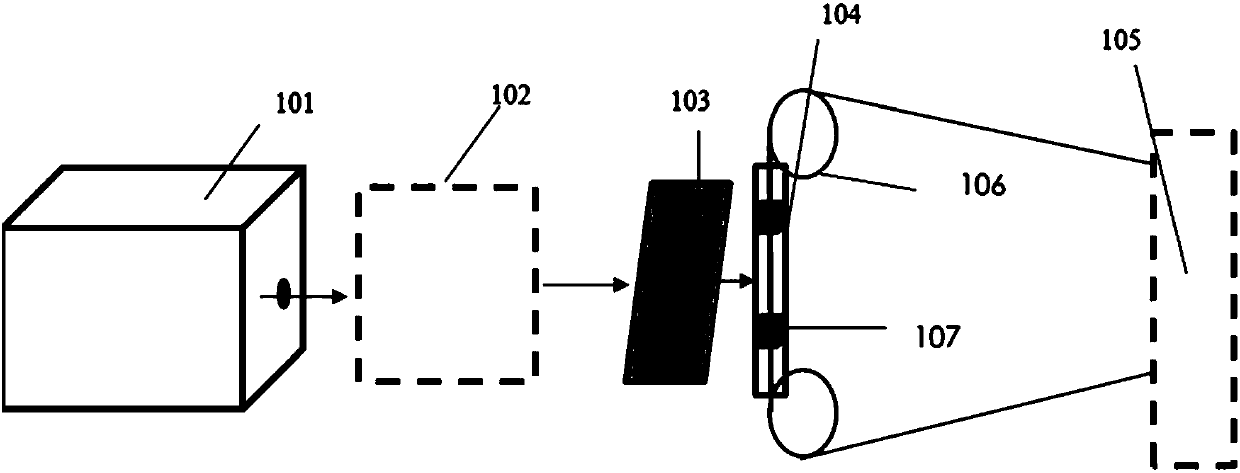

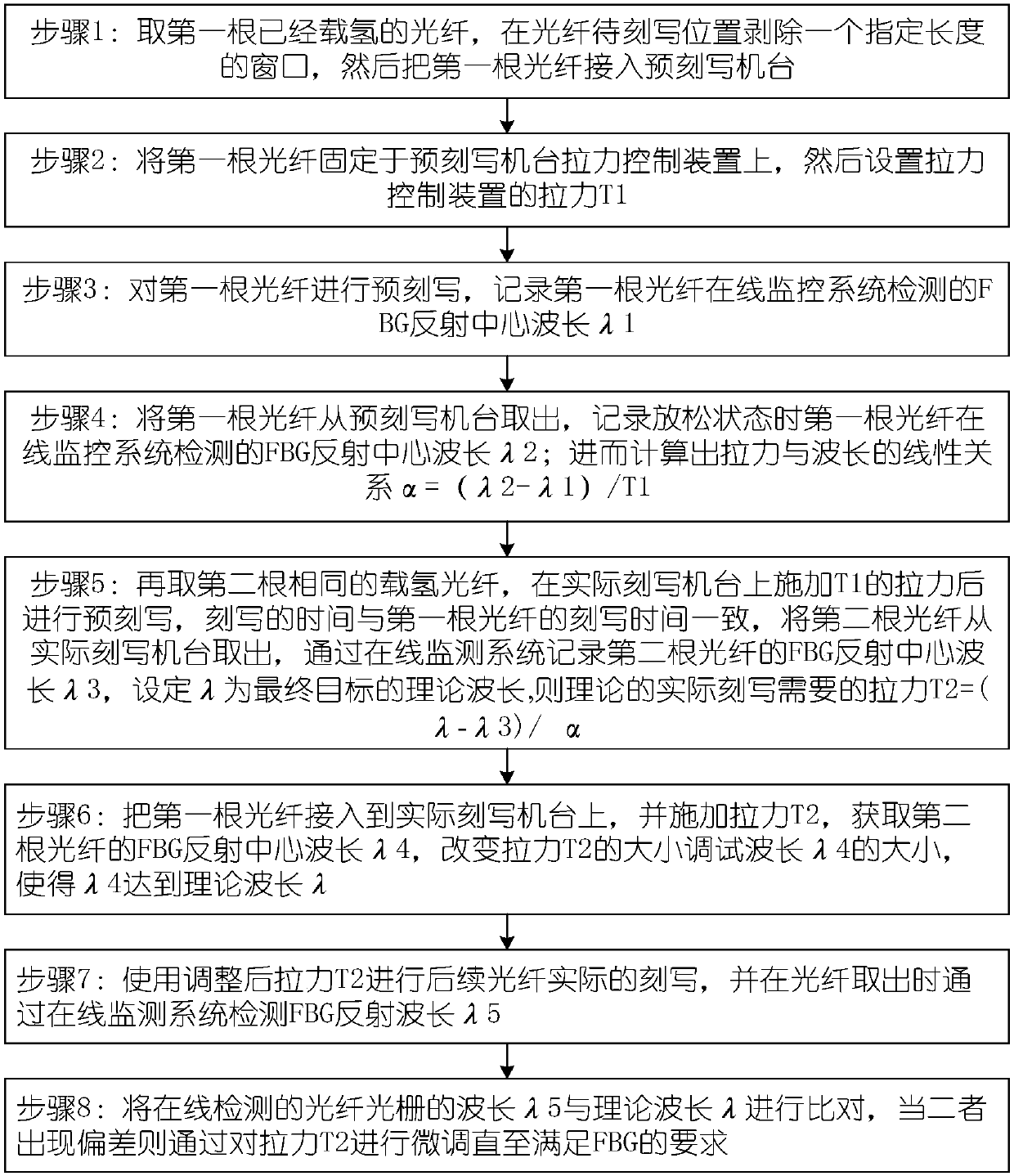

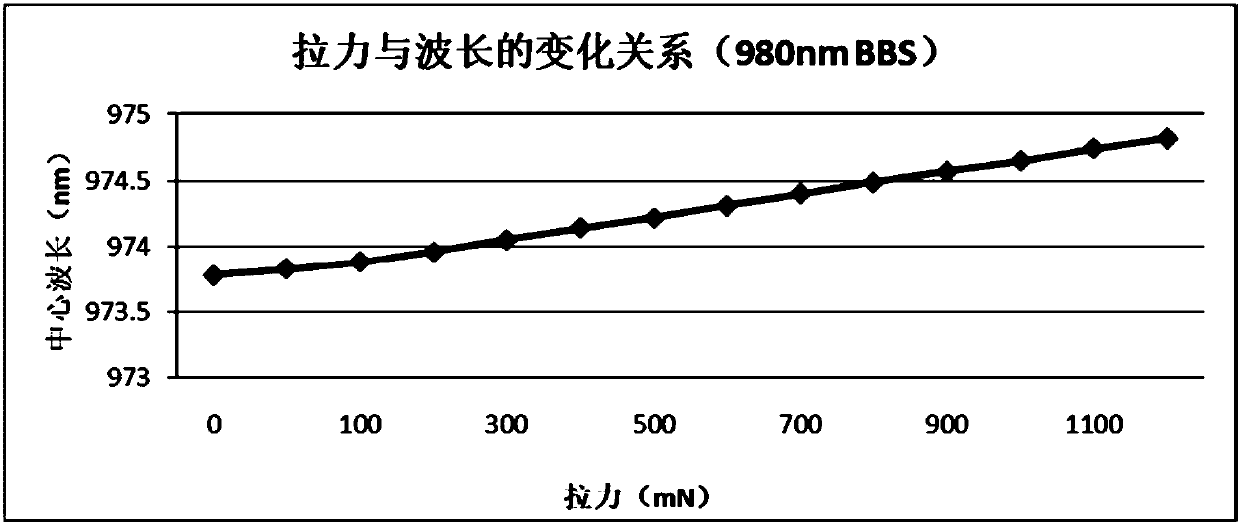

PendingCN110346863APrecise control of tensionPrecise Wavelength ControlCladded optical fibreOptical waveguide light guideFiberGrating

The invention discloses a method for controlling the FBG wavelength based on a double-grating structure. A fiber grating is inscribed in advance on a pre-inscribing machine bench; and a certain difference exists between the grating index and an actually required wavelength but is within a detection range of the broadband light source. The pre-inscribed grating is placed on an actual inscribing platform, wherein the main inscribing location avoids the pre-inscribing grating; after a tensile force is applied, the changing condition of the pre-inscribed grating is detected to determine whether the applied tensile force is corrected; and then normal inscribing is performed. According to the invention, one fiber grating having the same inscribing time and different wavelength is inscribed in advance; and then the tensile force is controlled accurately by controlling the wavelength changing condition of the pre-inscribed grating, so that the wavelength is controlled accurately.

Owner:FUZHOU PHOTOP QPTICS CO LTD

Crown belt tension control system

The invention provides a crown belt tension control system which comprises a transmission assembly, a driving assembly, a tension control assembly and a control unit. The transmission assembly comprises multiple conveying rollers. The driving assembly comprises a first servo motor and a driving roller connected to the output end of the first servo motor, and the driving roller is located between the two conveying rollers. The tension control assembly comprises a second servo motor and a tension swing arm so as to control the crown belt tension between the driving roller and a belt drum. The tension swing arm comprises a rotating roller which is located between the driving roller and the belt drum. At least one conveying roller is spaced between the rotating roller and the driving roller. The control unit carries out torque control over the second servo motor and provides stable torsion for the tension swing arm. The control unit further controls rotating speed of the first servo motor,thus the linear speed for feeding the crown belt at the driving roller is matched with the linear speed for winding the crown belt around the belt drum, and thus the tension swing arm can be maintained at a balance position. In this way, the crown belt tension control system can precisely control tension in the process of conveying the crown belt to the belt drum.

Owner:SAFE RUN & HISCENT MACHINERY SUZHOU

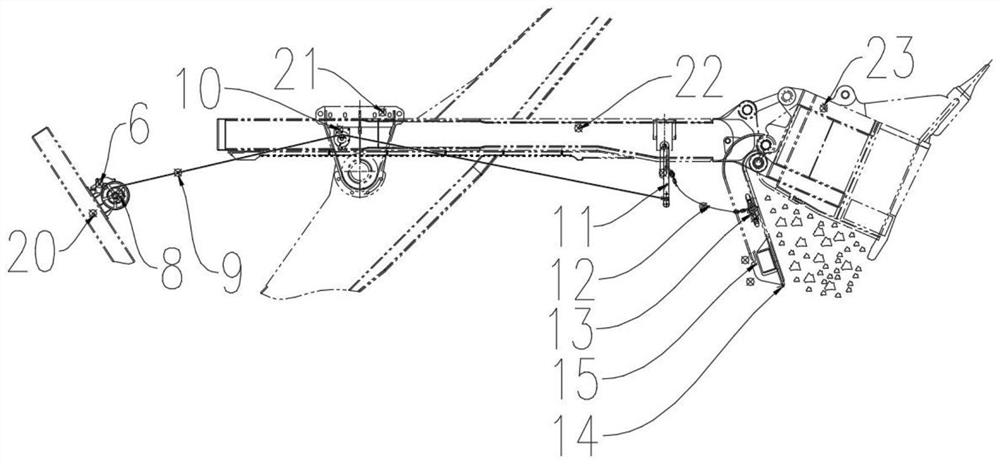

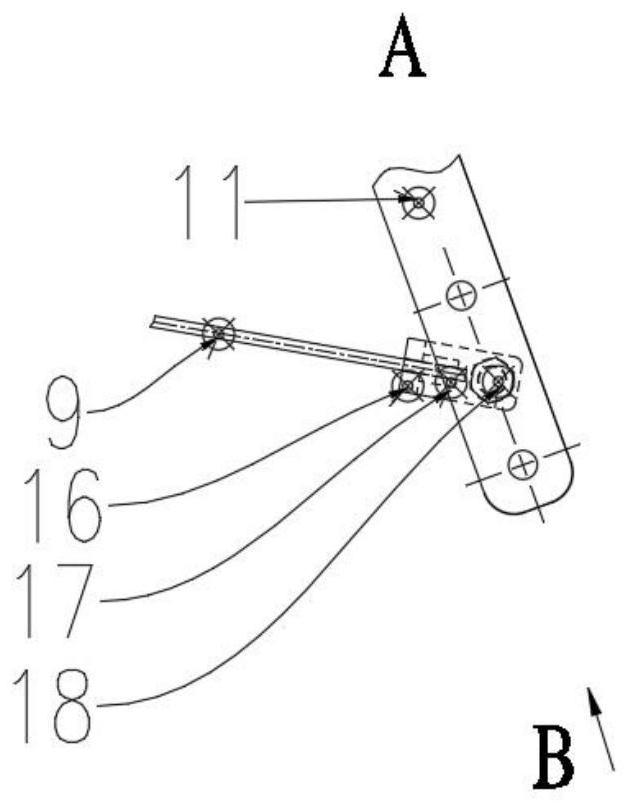

Bucket opening mechanism and construction device

PendingCN112281956AReduce stressExtend your lifeMechanical machines/dredgersElectric machineryMechanical drive

The invention provides a bucket opening mechanism and a construction device, and relates to the technical field of electric shovel bucket opening. The bucket opening mechanism comprises a mechanical transmission system, wherein the mechanical transmission system comprises a motor, a steel wire rope, a first-stage lever, a second-stage lever, a bucket bolt, a bucket bottom plate and a bucket rod; the motor, the steel wire rope, the first-stage lever, the second-stage lever and the bucket bolt are sequentially connected; the first-stage lever is arranged on the bucket rod; the second-stage leveris arranged on the bucket bottom plate; and the second-stage lever is suitable for driving the bucket bolt to slide so as to open the bucket bottom plate when swinging. According to the technical scheme, the two-stage lever structure is arranged, so that the bucket opening strength is improved, and effective bucket opening is guaranteed; and meanwhile, the stress of the steel wire rope is effectively reduced through the second-stage lever, so that the service life of the steel wire rope can be prolonged.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

A method for controlling the tension force of the induction diaphragm after welding of a capacitive thin film vacuum gauge

This application belongs to the technical field of mechanical processing, and discloses a method for controlling the tension force after welding the induction diaphragm of a capacitive thin film vacuum gauge, comprising the following steps: welding the sensing diaphragm to the cylindrical cavity of the capacitive thin film vacuum gauge The lower end of the body; the yield strength of the material of the cavity is lower than that of the sensing diaphragm; the pressure is unloaded after the pressure is applied on the inner wall of the cavity, so that when the pressure is applied, the inner part of the cavity wall of the cavity and the cavity of the cavity The outer part of the wall and the sensing diaphragm are in the state of plastic deformation, elastic deformation and elastic tension respectively, so that the sensing diaphragm has the required tension after unloading the pressure; the sensing diaphragm of the capacitive thin film vacuum gauge The tension control method after sheet welding is beneficial to realize the precise control of the tension force after induction diaphragm welding.

Owner:JIHUA LAB

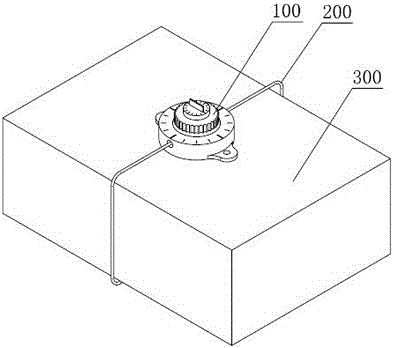

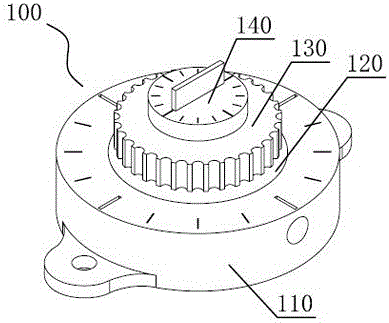

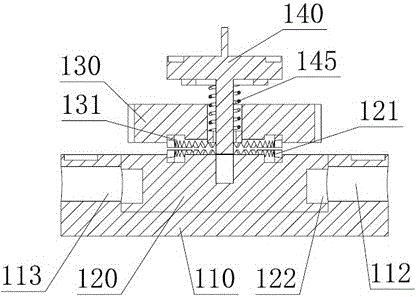

Quantitative numerical-control string winding machine

PendingCN113333634AImprove qualityImprove practicalityStringed musical instrumentsGrinding machinesPhysicsWinding machine

The invention relates to the technical field of accessory devices for string machining, in particular to a quantitative numerical-control string winding machine. The machine comprises a machine body frame, a left string core driving mechanism, a right string core driving mechanism and a string core tensioning mechanism; the string core tensioning mechanism comprises a tensioning sliding table and a first servo motor, the output end of the first servo motor is provided with a driving belt for driving the tensioning sliding table to move transversely, the right string core driving mechanism is connected with a tension sensor, a transverse moving sliding table mechanism is arranged at the top of the machine body frame, an external winding and unwinding mechanism, a wire stabilizing mechanism and a grinding mechanism are mounted on the transverse moving sliding table mechanism, the wire stabilizing mechanism comprises a first telescopic air cylinder, a first mounting frame and a first wire guide wheel, and the grinding mechanism comprises a second telescopic air cylinder, a second mounting frame, a clamping manipulator, a second servo motor and a grinding block. Grinding treatment is automatically carried out according to string technological setting, and a winding wire is stably transmitted to a string core through a damping pulley, so that the uniformity and compactness of the winding wire are ensured, the quality of the string is ensured, and the practicability is improved.

Owner:乐海乐器有限公司

Automatic fur plate supporting process

InactiveCN111826479AEven by forceAvoid shapelessnessSkins/hides/leather/fur manufacturing apparatusElectric machineryIndustrial engineering

The invention belongs to the technical field of fur processing, and relates to an automatic fur plate supporting process. The automatic fur plate supporting process comprises the following steps that1, the fur to be shaped is automatically feed; 2, the fur to be shaped is transferred to a bearing plate; step 3, the fur is automatically stretched and fixed; and 4, automatic discharging is carriedout. The automatic fur plate supporting process is ingenious in design and smooth in procedure connection, the fur is stretched through movement of a motor, stress is uniform, the stroke and the advancing speed of the motor can be set according to the size and the specification of the fur, and therefore the tensioning degree of fur supporting is accurately controlled, it is guaranteed that the furcannot be too loose, and the situation that the fur cannot be shaped is avoided; and according to the fur plate supporting process, the situation that the fur is damaged or cracked due to excessive tightness, and consequently badness is caused is avoided, so that the fur plate supporting shaping efficiency can be greatly improved, the fur plate supporting shaping yield can be greatly increased, and the fur plate supporting process has remarkable economic value.

Owner:曾建林

Unloading method of net frame lifting frames

ActiveCN102864938BPrecise control of tensionAvoid overstressingBuilding material handlingEngineeringMechanical engineering

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Packaging device

ActiveCN106428710APlay a protective effectAvoid over-tighteningBundling machine detailsConductor CoilMechanical engineering

The invention relates to the technical field of packaging, in particular to a packaging device. The packaging device comprises a pedestal, a wire winding plate, a wire winding knob and an adjustment knob. According to the packaging device disclosed by the invention, in a packaging process, when a preset rope tension is met, the wire winding knob is continuously rotated; as a slippage phenomenon occurs between a corrugated clamp spring I and a corrugated clamp spring II, a rope cannot be continuously tightened to avoid the phenomenon of extreme tightening, and a bound object can be protected; during unpackaging, the rope is not needed to be cut off or broken, but only the wire winding knob is rotated to the reverse direction, and then the rope can be loosened; assembling and disassembling are facilitated; furthermore, the rope can be repeatedly used, so that resources are saved; meanwhile, the meshing amount between the corrugated clamp spring I and the corrugated clamp spring II can be controlled through the adjustment knob, so that the tension of the rope can be precisely controlled, i.e. the looseness of a package, and the packaging device is easy to control and convenient to operate; moreover, the looseness of the package can be precisely controlled; the packaging device can realize quick packaging, and users do not worry about extreme tightening of the package; and the packaging device is extremely high in packaging efficiency.

Owner:ZHEJIANG SHENGHUABO ELECTRICAL APPLIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com