Dynamic and real-time monitoring method of prestressed tendon tension in concrete bridges and special prestressed construction system

A prestressed tendon, real-time monitoring technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as steel strand slippage, broken wire, single sensor detection point, and abnormal corresponding relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0166] The present invention will be further described below in conjunction with the examples, but not as a limitation to the present invention. The scope of protection of the present invention is based on the content of claims. protected range.

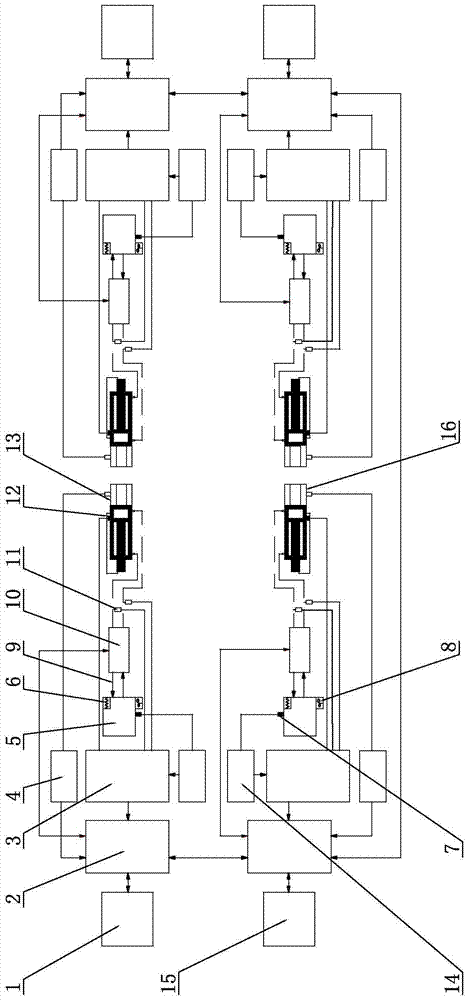

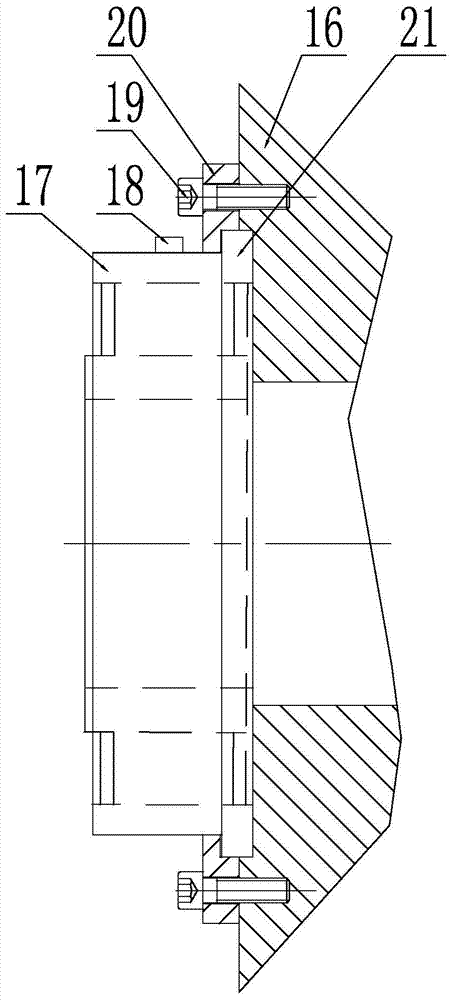

[0167] This embodiment consists of two sets of tensioning devices, namely A master and A slave and B master and B slave, which are divided into two groups and respectively arranged at both ends of the tensioned beam, such as figure 2 shown. The structural composition, working principle and dynamic real-time monitoring method of the tension force of the prestressed tendons of the two sets of tensioning devices are exactly the same, and now only one set of A main and B main is used as an example to illustrate. Each group of tensioning devices includes hydraulic station 5, reversing valve group 10, jack 16, A / D data acquisition module 3, PLC controller 2, central processing unit, man-machine interface 1, direct force measuring device,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com