Method and apparatus for assembly of portal crane in shipbuilding

A technology of gantry cranes and girders, applied in cranes, trolley cranes, transportation and packaging, etc., can solve problems such as troubles, and achieve the effects of convenient use, accurate adjustments, and smooth movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

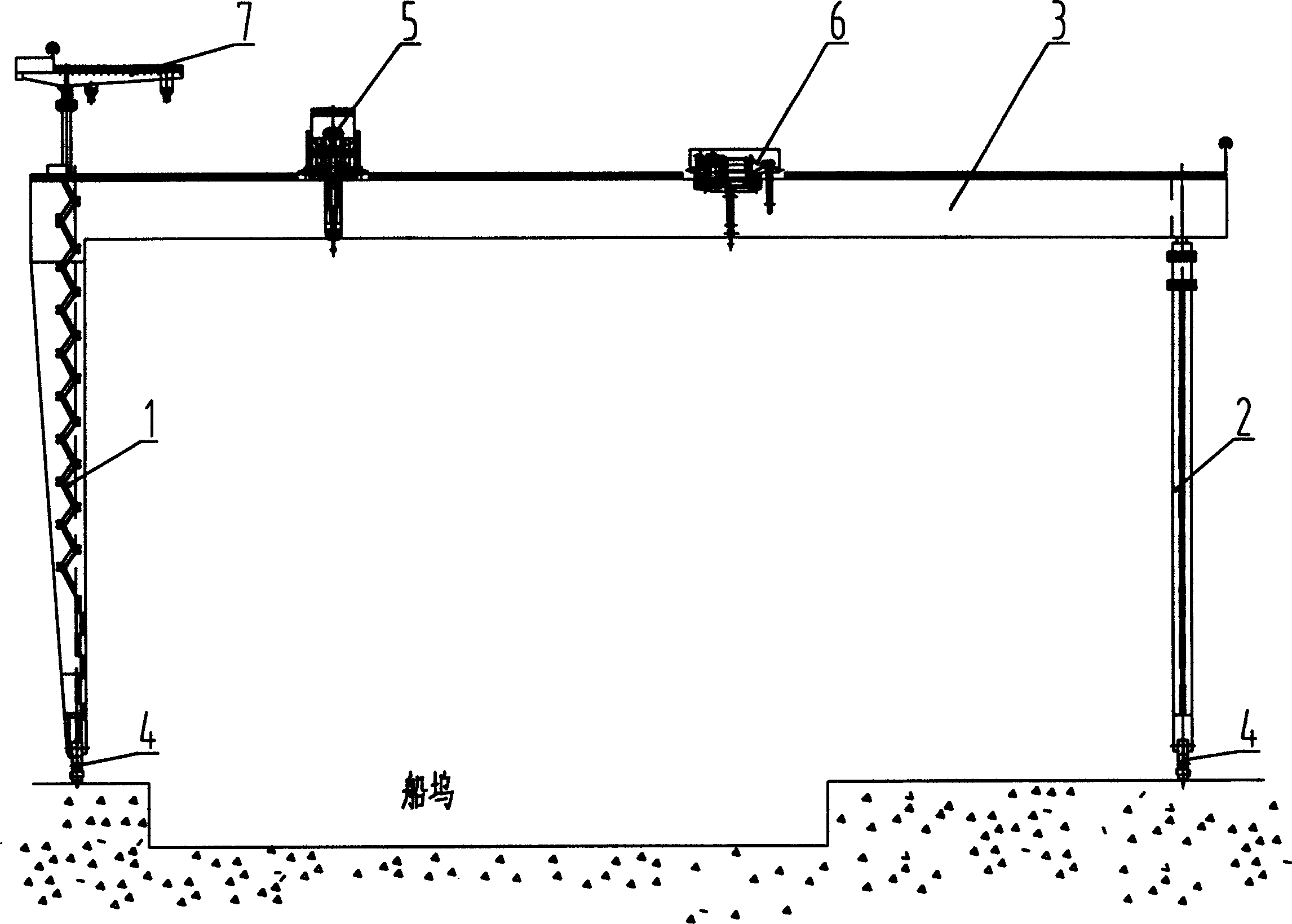

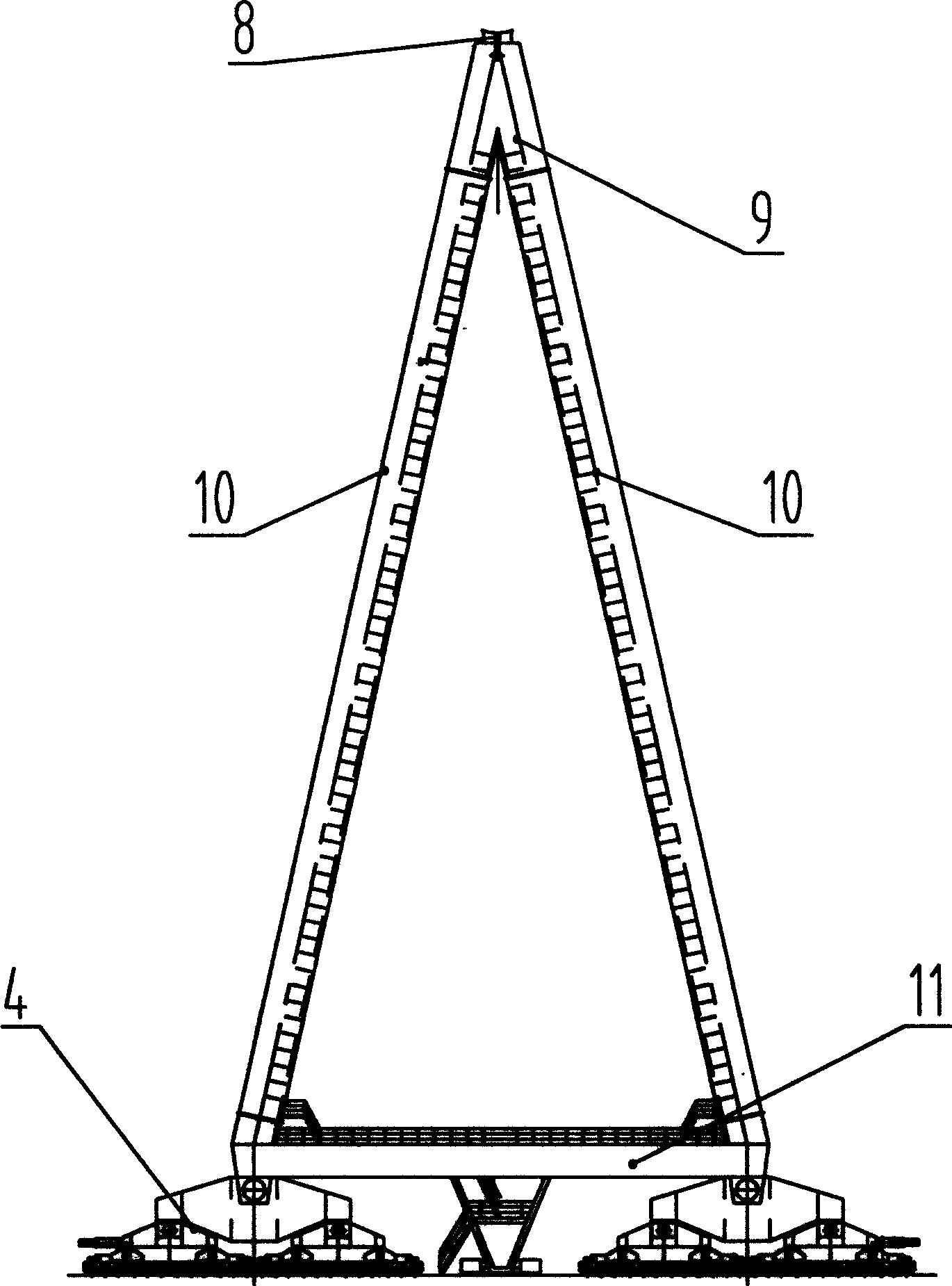

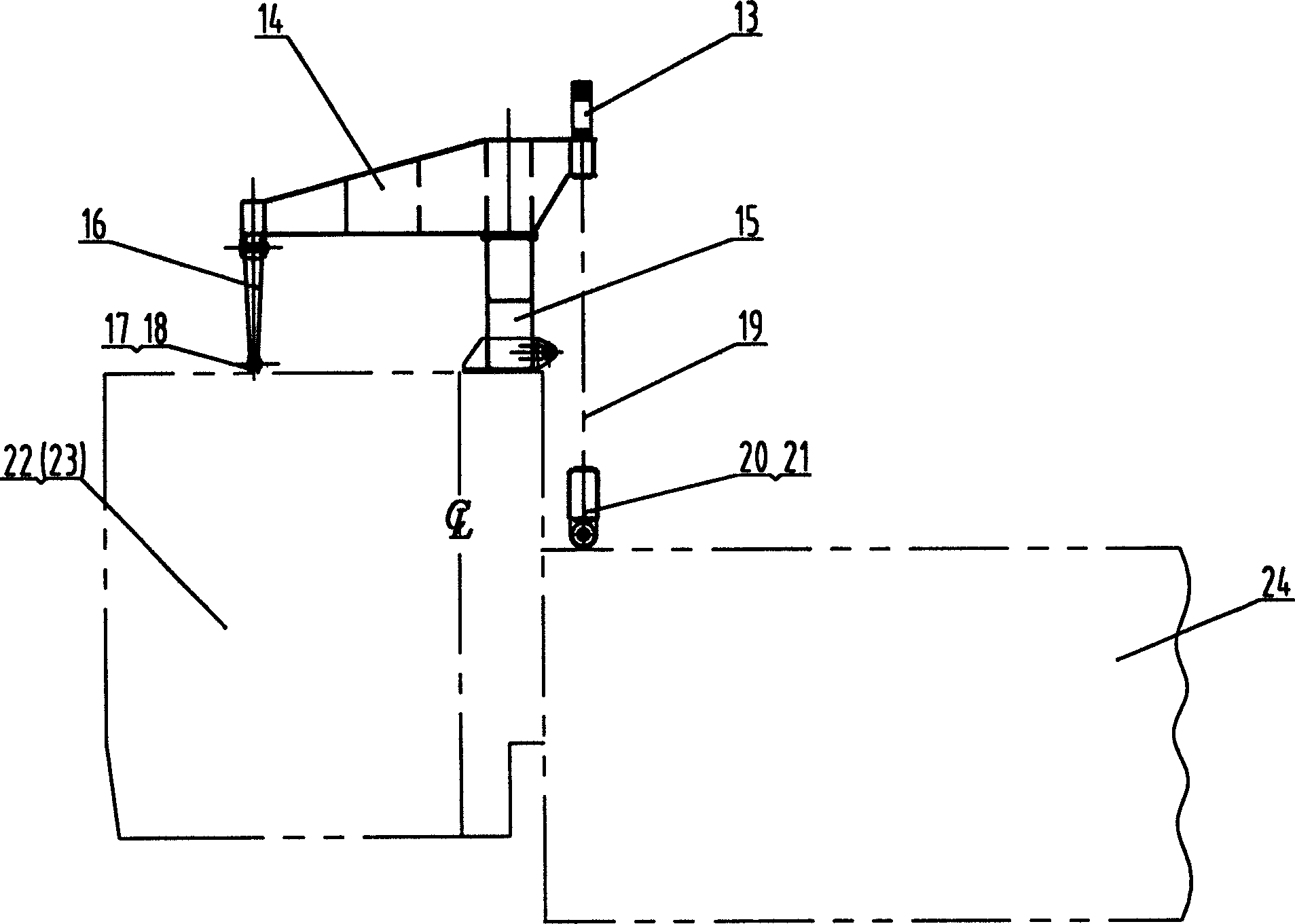

[0031] The present invention will be further described below through specific embodiments of the present invention in conjunction with the accompanying drawings. Such as figure 1 As shown, the 600t shipbuilding gantry crane includes rigid legs (1), flexible legs (2), girder (3), traveling mechanism (4), upper trolley (5), lower trolley (6), maintenance crane (7), where flexible legs such as figure 2 As shown, it includes a flexible hinge (8), an upper joint (9), a tie rod (10), and a lower beam (11); the machine has a lifting capacity of 600 tons, a gauge (span) of 185 meters, and a lifting height of 76 meters, the whole machine is 86 meters high, and its own weight is about 4,380 tons, of which the girder lifting part (including upper and lower trolleys, etc.) weighs 2,900 tons. It is a large-tonnage, long-span shipbuilding gantry crane.

[0032] The steps of the specific assembly method and the structure and function of the device used are as follows:

[0033] The main d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com