Non-contact flatness measurement model solving device

A measurement model, non-contact technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as complex calculation, low accuracy, and difficult maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

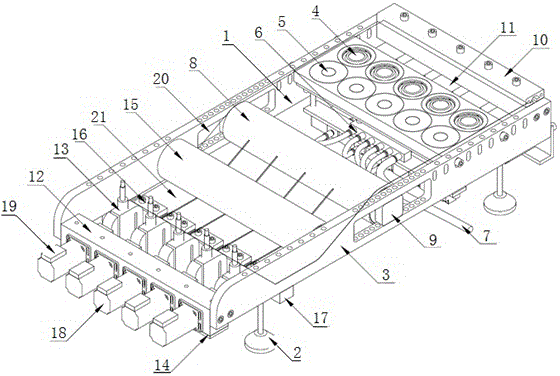

[0016] Attached below figure 1 The present invention is further described. attached figure 1 Schematically shows the non-contact plate shape measurement model solving device of the present invention, including a rectangular operating platform 1, a support seat 2 is provided below the operating platform 1, and side plates 3 are fixed on both sides, the operating platform 1 A pneumatic vibration-inducing suction cup 4 and a displacement sensor 5 are arranged on it, and the pneumatic vibration-inducing suction cup 4 is connected with an air circuit distributor 6 and a control device, and the air circuit distributor 6 is connected with an air pressure source inlet 7 through a high-frequency valve . According to the properties of the strip 20, the required air flow and the high-frequency valve parameters are set in the control device, and the air flow is input into the air distributor 6 through the air pressure source inlet 7, and the air distributor 6 sends the air flow to Each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com