Weaving machine

A ribbon loom and frame technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of time-consuming and laborious, many drives, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

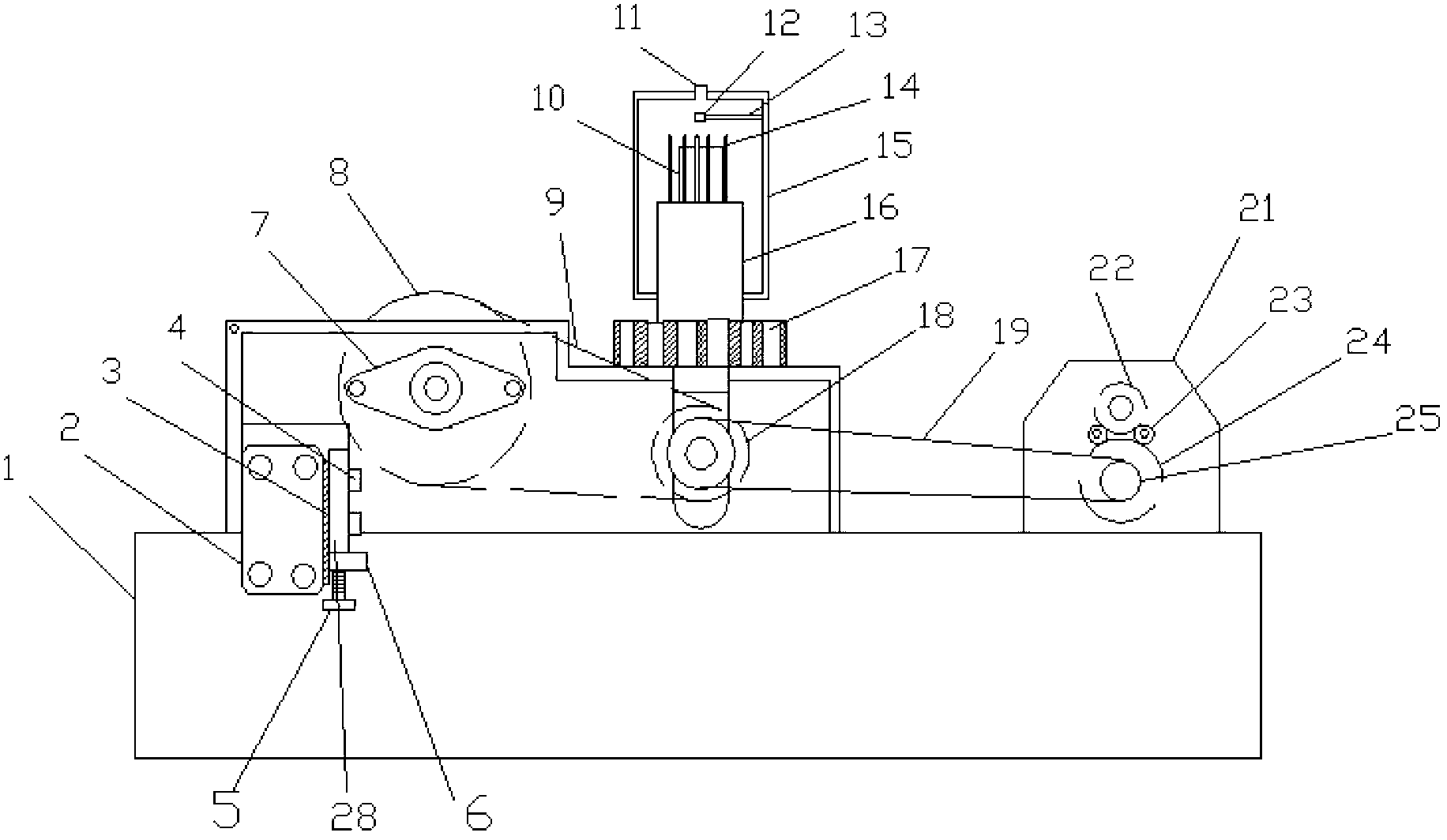

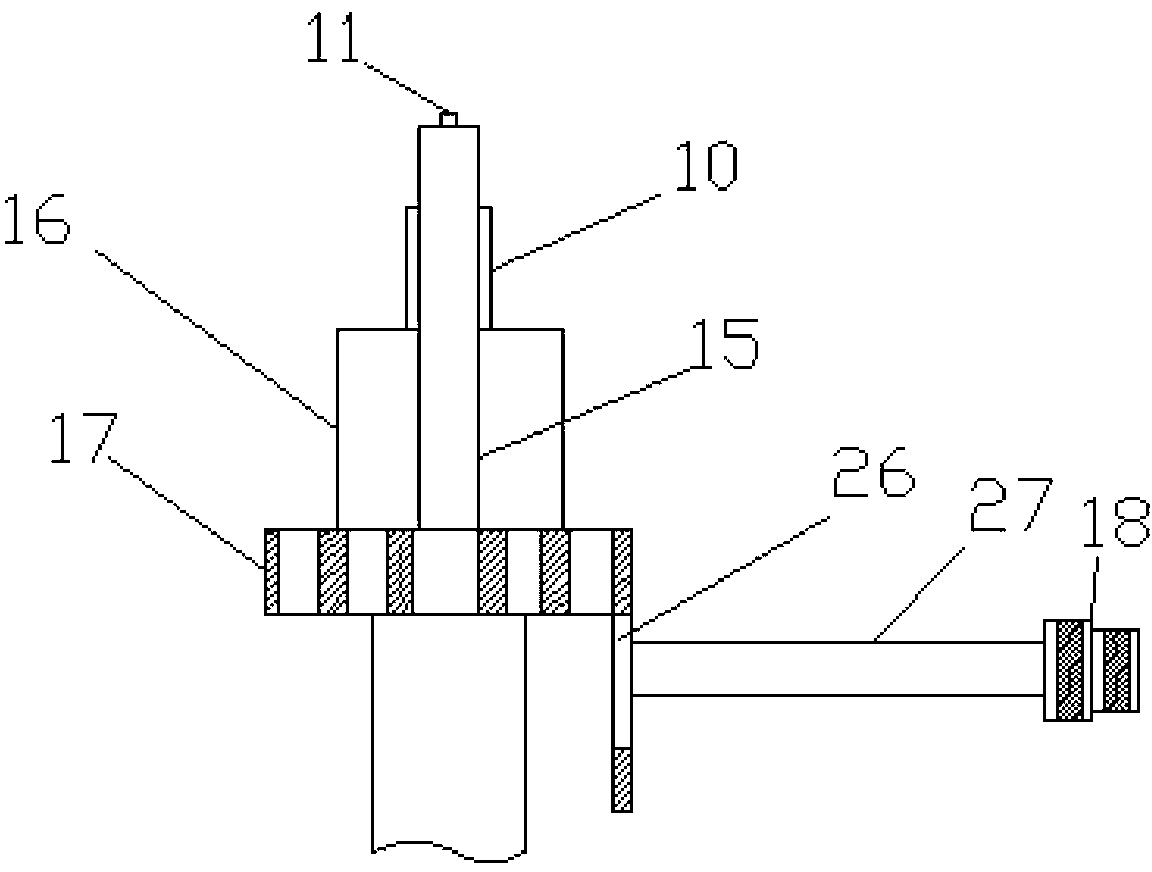

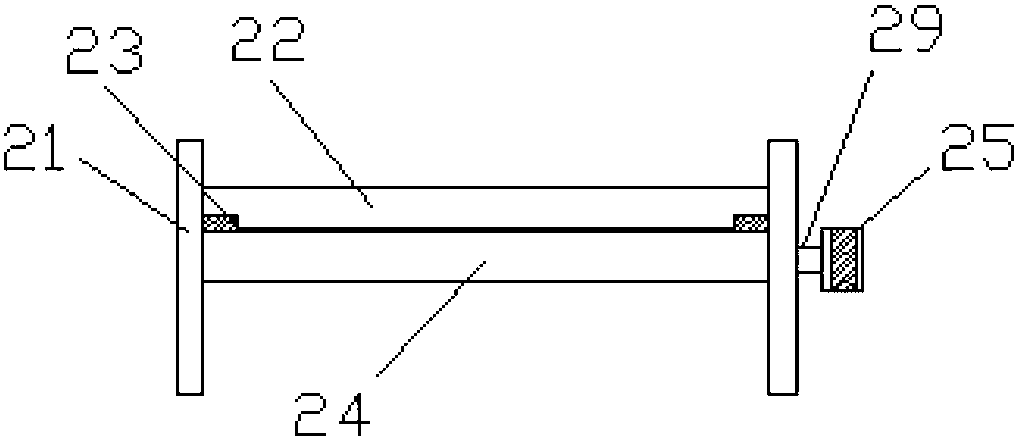

[0016] combine Figure 1 to Figure 3 A weaving machine shown includes a frame 1, a transmission mechanism and a weaving part, and is characterized in that the transmission mechanism is integrally formed, including a top frame 2, a guide rail plate 3, a positioning bolt 4, an adjustment screw 5, and a fixed block 6. The moving plate 28, the bearing seat 7 and the pulley 8, a guide rail plate 3 is fixedly installed on the top frame (2), and a moving plate 28 is provided on one side of the guide rail plate 3, and the moving plate 28 passes through the positioning bolt 4 Fixed on the guide rail plate 3, a fixed block 6 is fixedly arranged under the moving plate 28, the fixed block 6 is provided with a screw hole matched with the adjusting screw rod 5, and the pulley 8 passes through the screw hole on the bearing seat 7. The shaft is threaded therein, and the braided parts are integrally formed, including a fuselage 16, and the fuselage 16 is threaded and fixed on a horizontal gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com