Ultrathin lithium foil and preparation method thereof

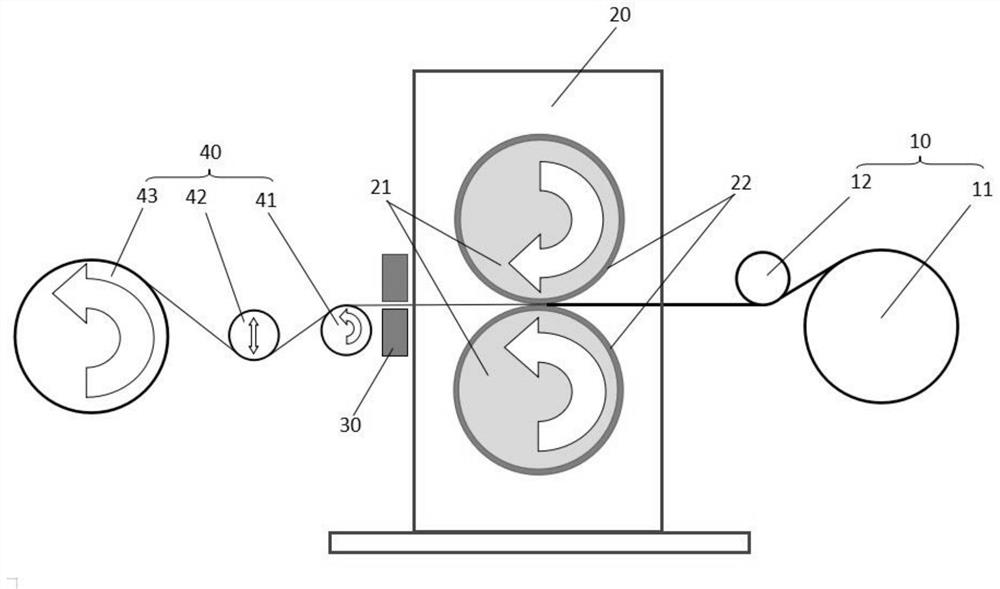

A technology of ultra-thin lithium and foil materials, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problem that lithium metal is easy to stick, it is difficult to produce 20 micron thick rolled lithium foil, sticky rolls, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

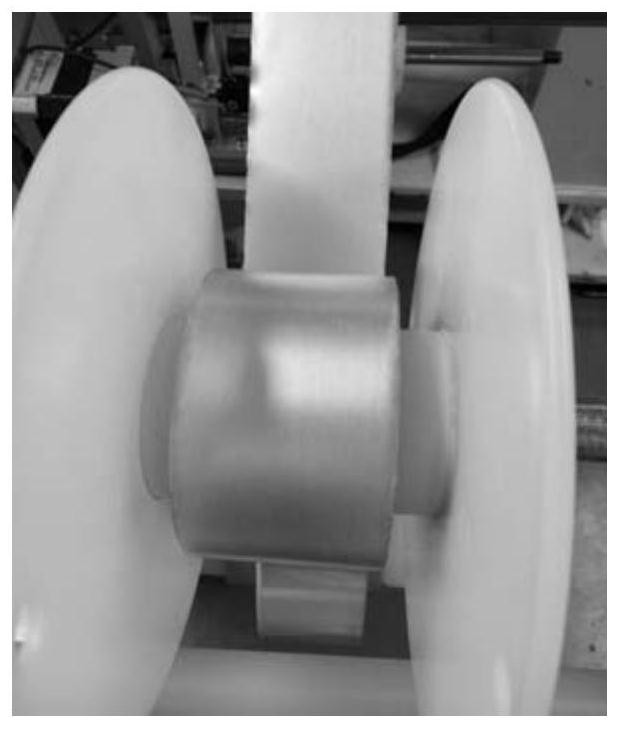

[0038] Use a metal lithium strip with a lithium content of 99.95% and a thickness of 160 microns, auxiliary unwinding and winding devices, roll thinning with organosilicide-coated rolls, the first rolling, and control the rolling compression ratio to 2, Obtaining a lithium strip with a thickness of 80 microns; through the second rolling, controlling the rolling compression ratio to be 2, and preparing a metal lithium strip with a thickness of 40 microns; after the third rolling, controlling the rolling compression ratio is 2, the thickness is 20 microns ultra-thin lithium foil, and the thickness tolerance is ±1 micron. The prepared 20 micron thick lithium foil product and the rolled 20 micron thick lithium foil product such as figure 2 , 3 shown.

Embodiment 2

[0040] The metal lithium strip with a lithium content of 99.93% and a thickness of 130 microns is adopted, with auxiliary unwinding and winding devices, thinning through polyethylene-coated rolls, rolling for the first time, and controlling the rolling compression ratio to be 2 to obtain Thickness is the lithium strip material of 65 microns; Through rolling for the second time, the control rolling compression ratio is 2, and the preparation obtains the metal lithium strip material that thickness is 32 microns; Pass through the 3rd rolling again, the control rolling compression ratio is 2. Obtain an ultra-thin lithium foil with a thickness of 16 microns and a thickness tolerance of ±1 micron. The prepared 16 micron thick lithium foil product and the rolled 16 micron thick lithium foil product such as Figure 4 , 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com