Preparation method of reinforced polyvinyl alcohol compound

A technology for polyvinyl alcohol and compound, which is applied in the field of preparation of reinforced polyvinyl alcohol compound, and can solve the problems of complex treatment method and severe conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

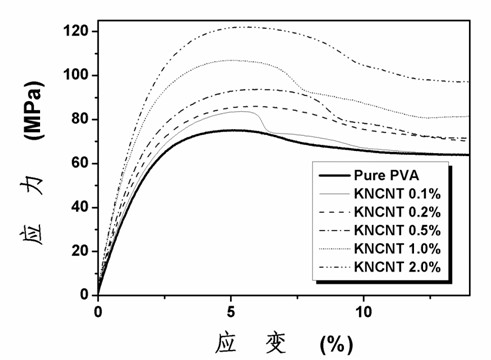

Embodiment 1

[0025] In a 25 ml white sample bottle, add 100ml dimethyl sulfoxide, 0.2g Kevlar fiber, 0.3g potassium hydroxide, 50 o C under stirring to dissolve. Add 0.25 ml ultrasonically dispersed Kevlar / MWNT aqueous dispersion (4 mg / ml), 1 g polyvinyl alcohol, add 14.75 ml deionized water, heat and stir at 40°C for 4 h to obtain a uniformly dispersed solution. Cast to form a film, and vacuum dry at 65°C for 24 hours, then raise the temperature to 90°C and dry for 24 hours.

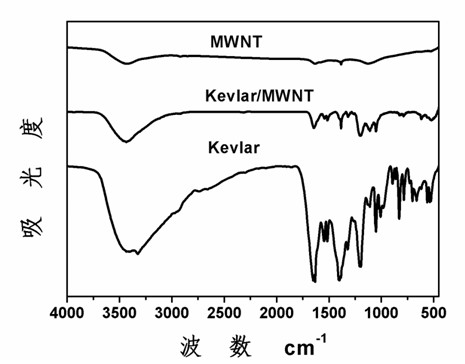

[0026] figure 1 Infrared spectra of multi-walled carbon nanotubes (MWNT), Kevlar nanofibers (Kevlar) and Kevlar nanofibers non-covalently modified multi-walled carbon nanotubes (Kevlar / MWNT). In the infrared spectrum of Kevlar / MWNT, 1644 cm -1 A peak representing the C=O bond appeared at 1545 cm -1 A peak representing the C-N bond appeared at , which proved that the Kevlar nanofibers were adsorbed on the surface of the multi-walled carbon nanotubes, and the non-covalent modification was successful.

Embodiment 2

[0028] In a 25 ml white sample bottle, add 100ml dimethyl sulfoxide, 0.2g Kevlar fiber, 0.3g potassium hydroxide, 50 o C under stirring to dissolve. Add 0.625 ml ultrasonically dispersed Kevlar / MWNT aqueous dispersion (4 mg / ml), 1 g polyvinyl alcohol, add 14.375 ml deionized water, heat and stir at 40°C for 4 h to obtain a uniformly dispersed solution. Cast to form a film, and dry at 65°C for 24 hours, then raise the temperature to 90°C and dry for 24 hours.

Embodiment 3

[0031] In a 25 ml white sample bottle, add 100ml dimethyl sulfoxide, 0.2g Kevlar fiber, 0.3g potassium hydroxide, 50 o C under stirring to dissolve. Add 1.25 ml ultrasonically dispersed Kevlar / MWNT aqueous dispersion (4 mg / ml), 1 g polyvinyl alcohol, add 13.75 ml deionized water, heat and stir at 40°C for 4 h to obtain a uniformly dispersed solution. Cast into film. And dry at 65°C for 24 hours, then raise the temperature to 90°C and dry for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com