Fabric architectures for improved ballistic impact performance

a technology of fabric architecture and ballistic impact, applied in the direction of weaving, protective fabrics, other domestic articles, etc., can solve the problems of reducing v50 performance, reducing production cost, and not providing adequate backface deformation resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

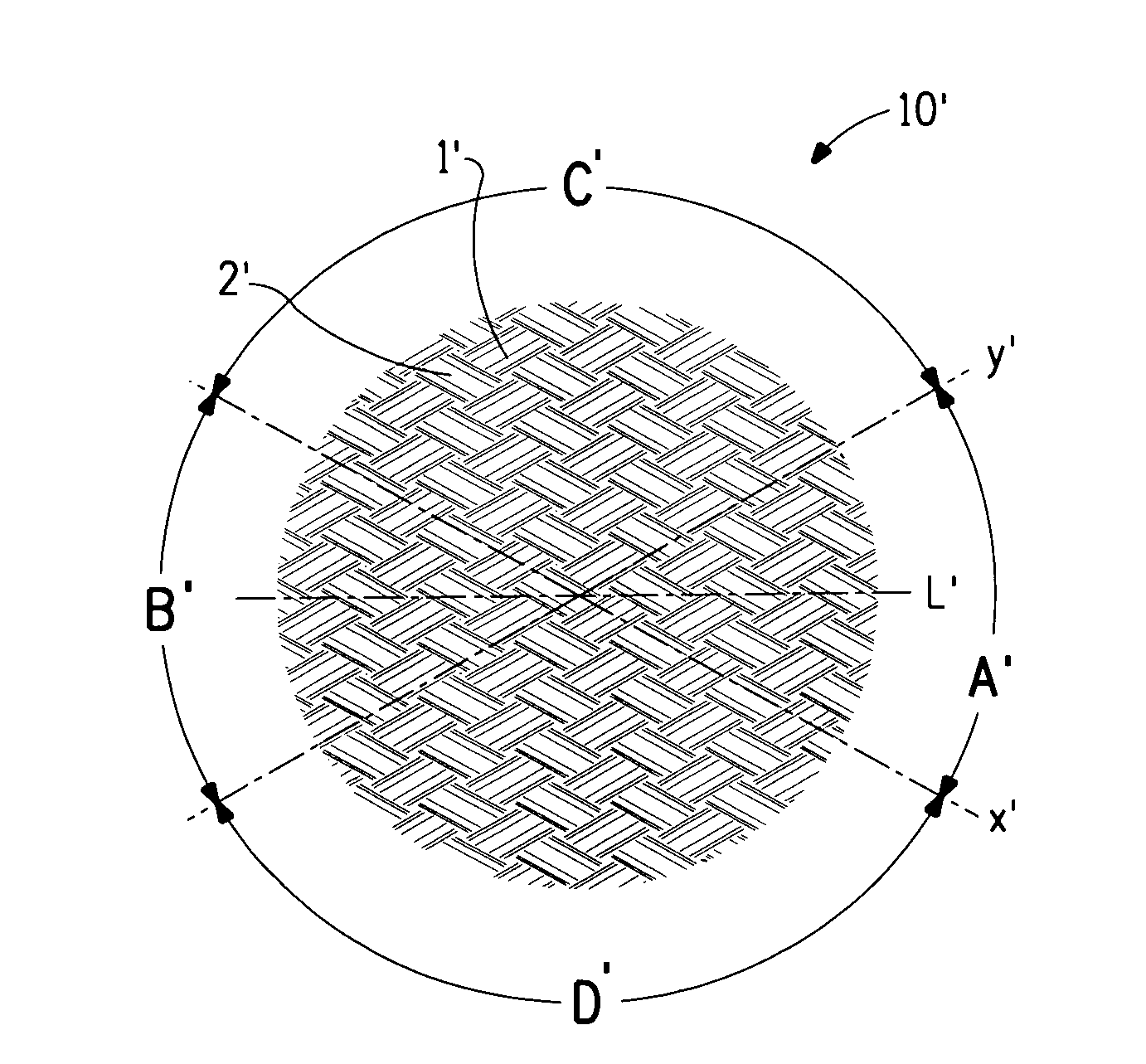

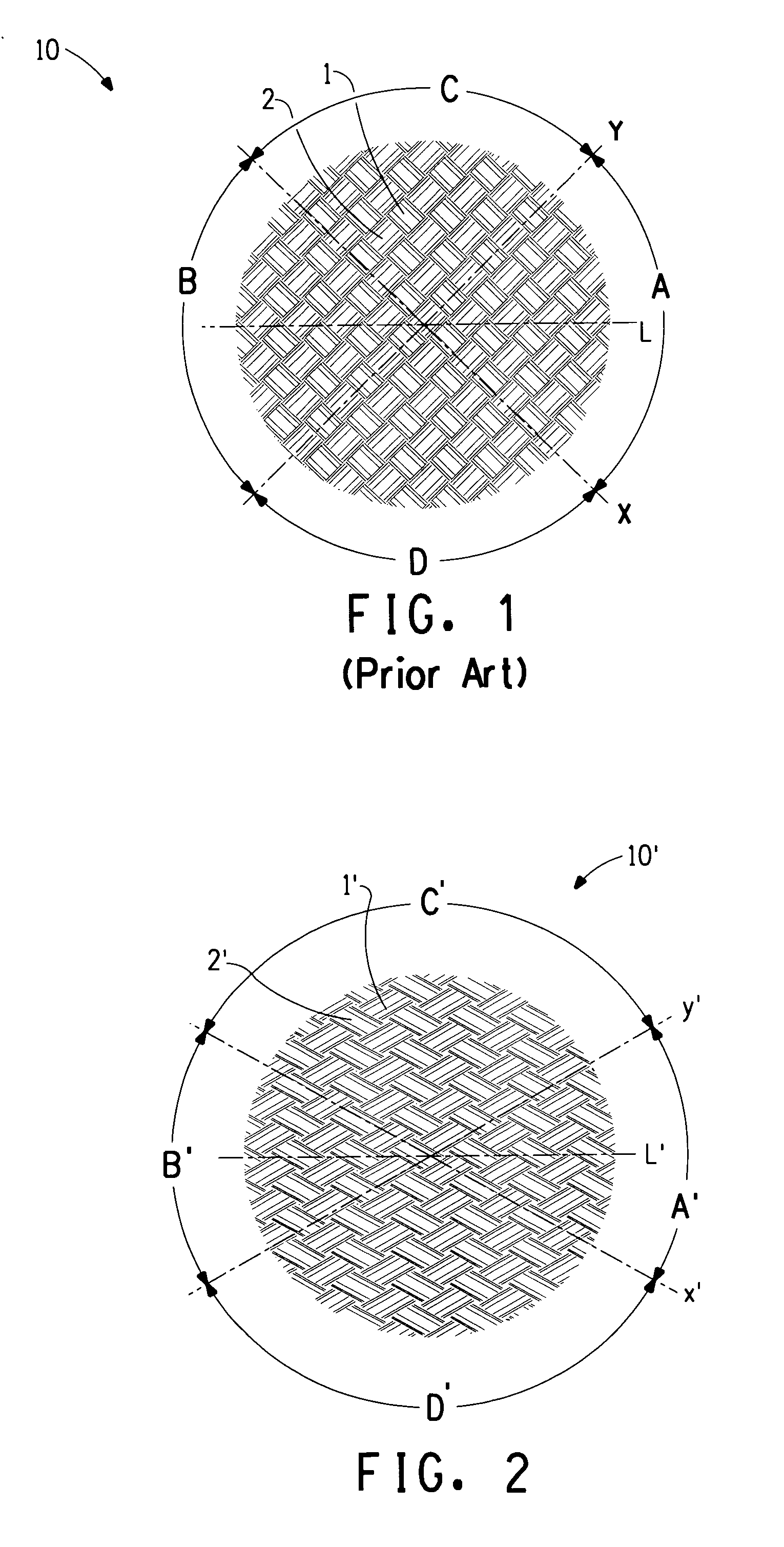

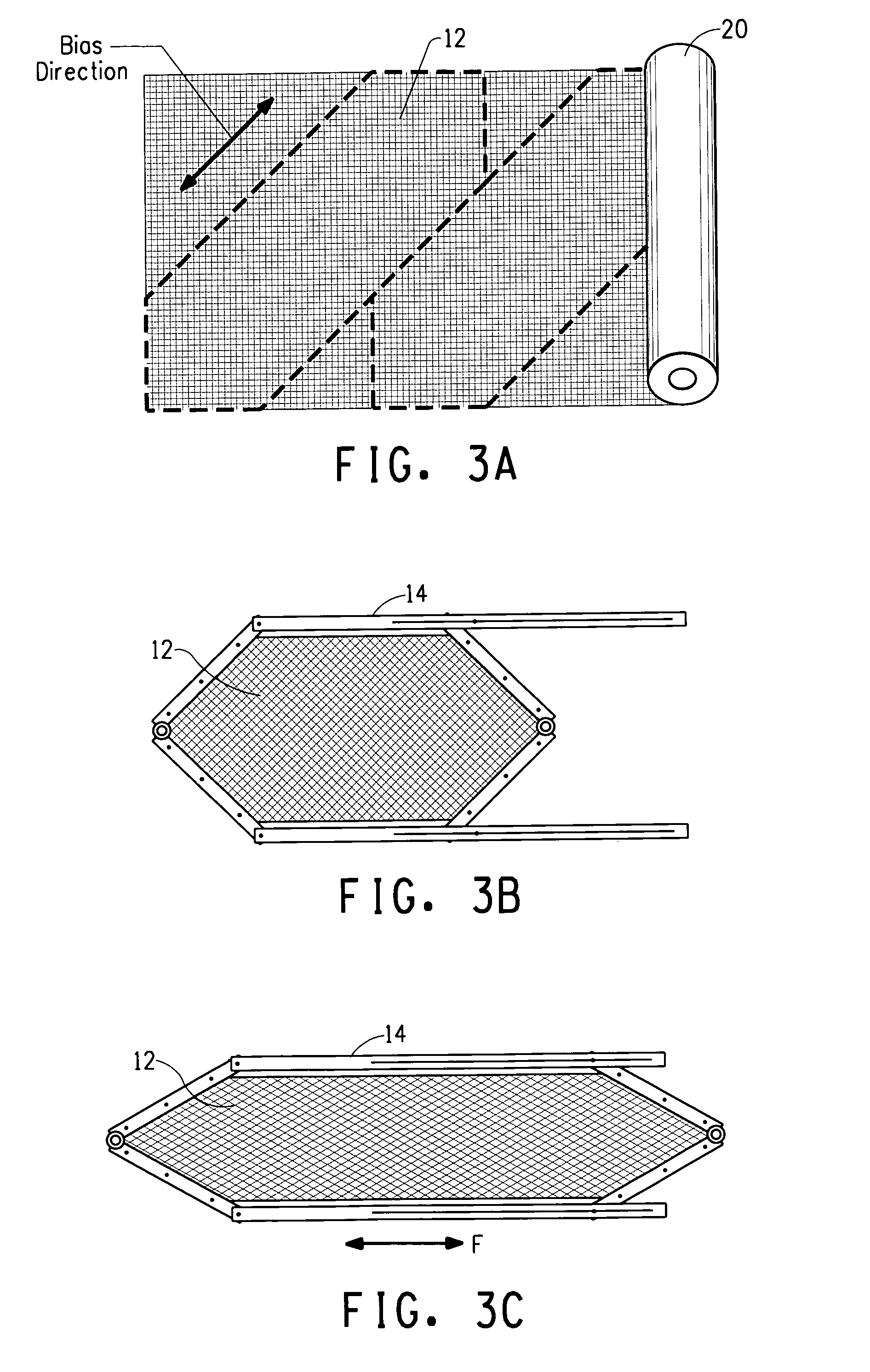

[0056]Diagonal strips were cut from a 63 in (160 cm) wide roll of the 840 denier Kevlar® 129 yarn, 18 ends per inch warp, 18 ends per inch fill greige fabric described in Comparative Example 2. The diagonal cuts were oriented along the bias direction of this plain weave fabric as shown in FIG. 3A; generating bias-oriented fabric strips 28 in (71 cm) in width. The fabric was clamped in a trellising frame as illustrated in FIG. 3B and extended to achieve a 45 degree acute trellis angle. The trellised fabric was cut into equal sections and cross-laid (stacked in an alternating layer fashion, with every layer having a trellis direction rotated 90 degrees relative to the one before it). The stack was constructed with the aid of a square pinning frame that held the trellis angle of individual fabric layers fixed during construction. This alternating cross-laid arrangement of fabric layers was repeated to create a stack with 26 trellised fabric layers. The stack of fabric layers were stitc...

example 2

[0057]Diagonal strips were cut from a 63 in (160 cm) wide roll of the 600 denier Kevlar® KM2 yarn, 17 ends per inch warp, 17 ends per inch fill greige fabric described in Comparative Example 2. The diagonal cuts were oriented along the bias direction of this plain weave fabric as shown in FIG. 3A, generating bias-oriented fabric strips. The fabric was clamped in a trellising frame as illustrated in FIG. 3B and extended to achieve a 30 degree acute trellis angle. The trellised fabric was cut into equal sections and cross-laid (stacked in an alternating layer fashion, with every layer having a trellis direction rotated 90 degrees relative to the one before it). The stack was constructed with the aid of a square pinning frame that held the trellis angle of individual fabric layers fixed during construction. This alternating cross-laid arrangement of fabric layers was repeated to create a stack with 27 trellised fabric layers. The stack of fabric layers were stitched together about thei...

example 3

[0058]A multilayer panel comprised of a trellised fabric architecture generated using the 20×20 ends per inch, 840 denier Kevlar® 129 yarn crow's foot weave fabric described in Comparative Example 6, was generated using the procedure described for Experimental example 1 above. The finished test panel was comprised of 23 layers, each having a 45 degree trellis angle, the layers being stacked in a 0 degree-90 degree alternating orientation as done in experimental example 1. The panel was sewn about the perimeter and with a 2 in×2 in (5.1×5.1 cm) quilt pattern. The backface signature and V50 results for 44 Magnum bullets at 1430±30 ft / s against a clay witness appear in Table 3.

[0059]This example exhibited improved backface without significant loss in V50 when compared with the target fabricated from the base fabric in Comparative Example 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| vertical angles | aaaaa | aaaaa |

| vertical angles | aaaaa | aaaaa |

| vertical angles | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com