Alloy wire and preparation method and application thereof

A technology of alloy wire and tungsten alloy, which is applied in the field of alloy wire and its preparation, can solve problems such as poor toughness, difficulty in mass production, and complicated production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

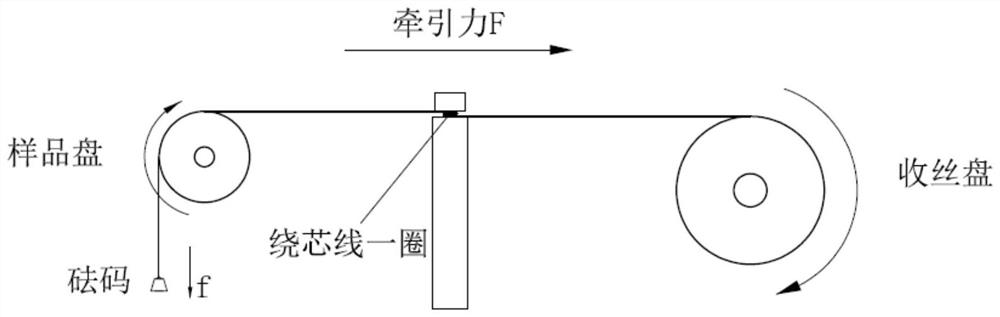

Image

Examples

preparation example Construction

[0058] The invention provides a method for preparing an alloy wire rod:

[0059] The steps of the preparation method include doping powder making, pressing, sintering, blanking, pressure processing, etc.;

[0060] doping, reducing, powder mixing,

[0061] Wherein, the doped pulverization is divided according to different process methods, including solid-liquid, liquid-liquid and solid-solid methods;

[0062] Specifically, based on the solid-liquid method, the doping pulverization includes the following steps:

[0063] Solid-liquid doping, reduction, pulverization;

[0064] The method of solid-liquid doping includes: doping an appropriate amount of soluble lanthanum salt solution into tungsten powder, and after fully stirring, heating and drying in stages to obtain the product;

[0065] The staged heating and drying adopts a low-temperature drying method first and then a high-temperature drying method, that is, drying is carried out at a temperature lower than 100°C, so that...

Embodiment approach

[0077] In addition, steps such as reduction and milling in the above steps are preferably but not limited to the following implementations, namely:

[0078] Reduction: the material obtained by doping solid-liquid and / or liquid-liquid is reduced into alloy powder once in a four-temperature zone reduction furnace;

[0079] Powder making: Mix the alloy powder obtained after reduction, and put the alloy powder with an average Fischer grain size of 1.0-4.0 μm into the powder mixer after mixing. Mix the powder at a speed of 6-10 rpm for 60-90 minutes;

[0080] Powder compaction: Using isostatic pressing, the powder with an average Fibonacci particle size of 1.0 μm to 4.0 μm is pressed into a green compact with a unit weight of 1.5 kg to 5.0 kg through a pressure of 160 MPa to 260 MPa, and the green compact is pressed in a hydrogen atmosphere. Carry out pre-sintering, the temperature of the pre-sintering is preferably 1200-1400°C, to increase the compact strength;

[0081] Sinterin...

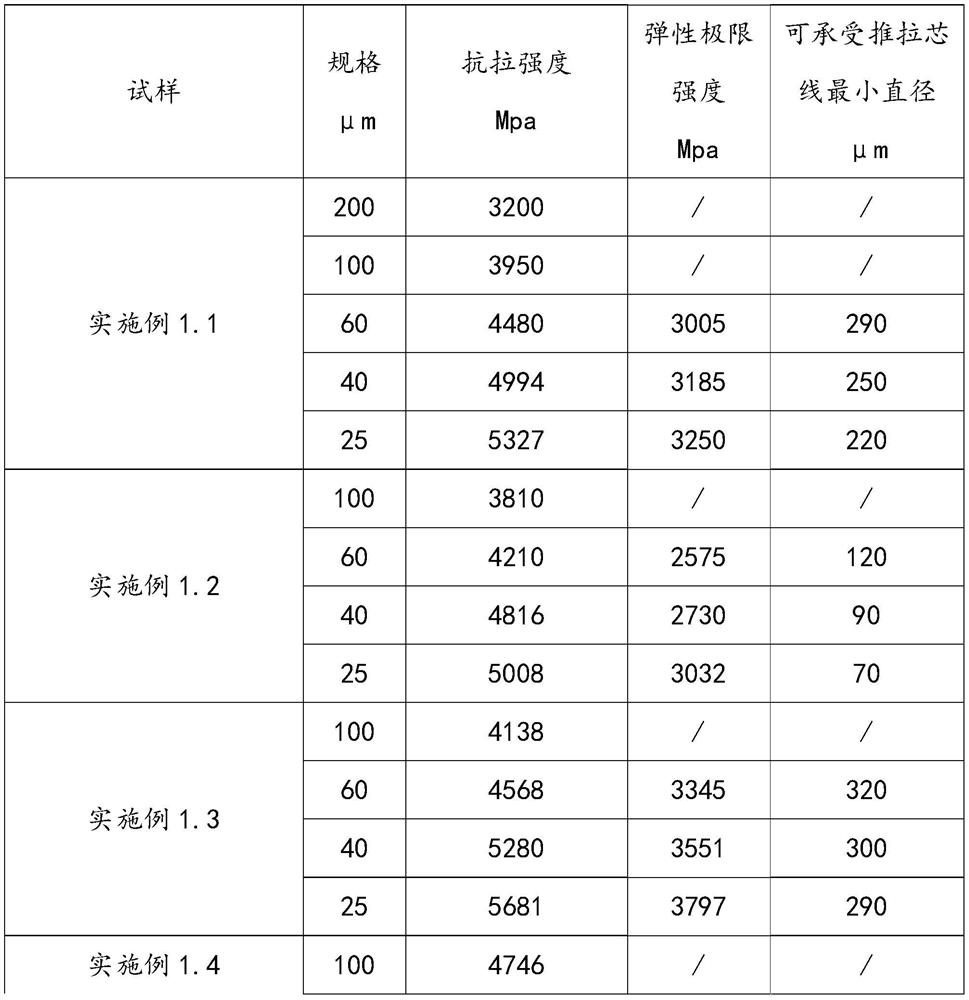

Embodiment 11

[0094] This group of embodiment is to prepare a kind of high-strength and high-toughness tungsten alloy wire rod according to the present invention, and its material element composition is: La 2 o 3 is 1wt%, and W is 99wt%.

[0095] Its preparation steps are as follows:

[0096] Step 1. Doping: uniformly dope an appropriate amount of lanthanum nitrate solution into the blue tungsten powder, and after fully stirring, dry at a low temperature of 80°C for 4 hours and then dry at a high temperature of 120°C;

[0097] Step 2. Reduction: the material obtained in step 1 is reduced into an alloy powder with a suitable particle size at one time in a reduction furnace with four temperature zones;

[0098] Step 3, powder mixing: put the materials obtained in step 2 into a powder mixing machine according to different particle sizes. Mix the powder for 80 minutes at a speed of 8 rpm;

[0099]Step 4. Powder compaction: The powders with different particle sizes are pressed by isostatic p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com