Substrate incorporating non-woven elements

a non-woven element and substrate technology, applied in the field of textile substrates, can solve the problems of short circuit, elongated items such as wiring harnesses, and may endure harsh environmental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

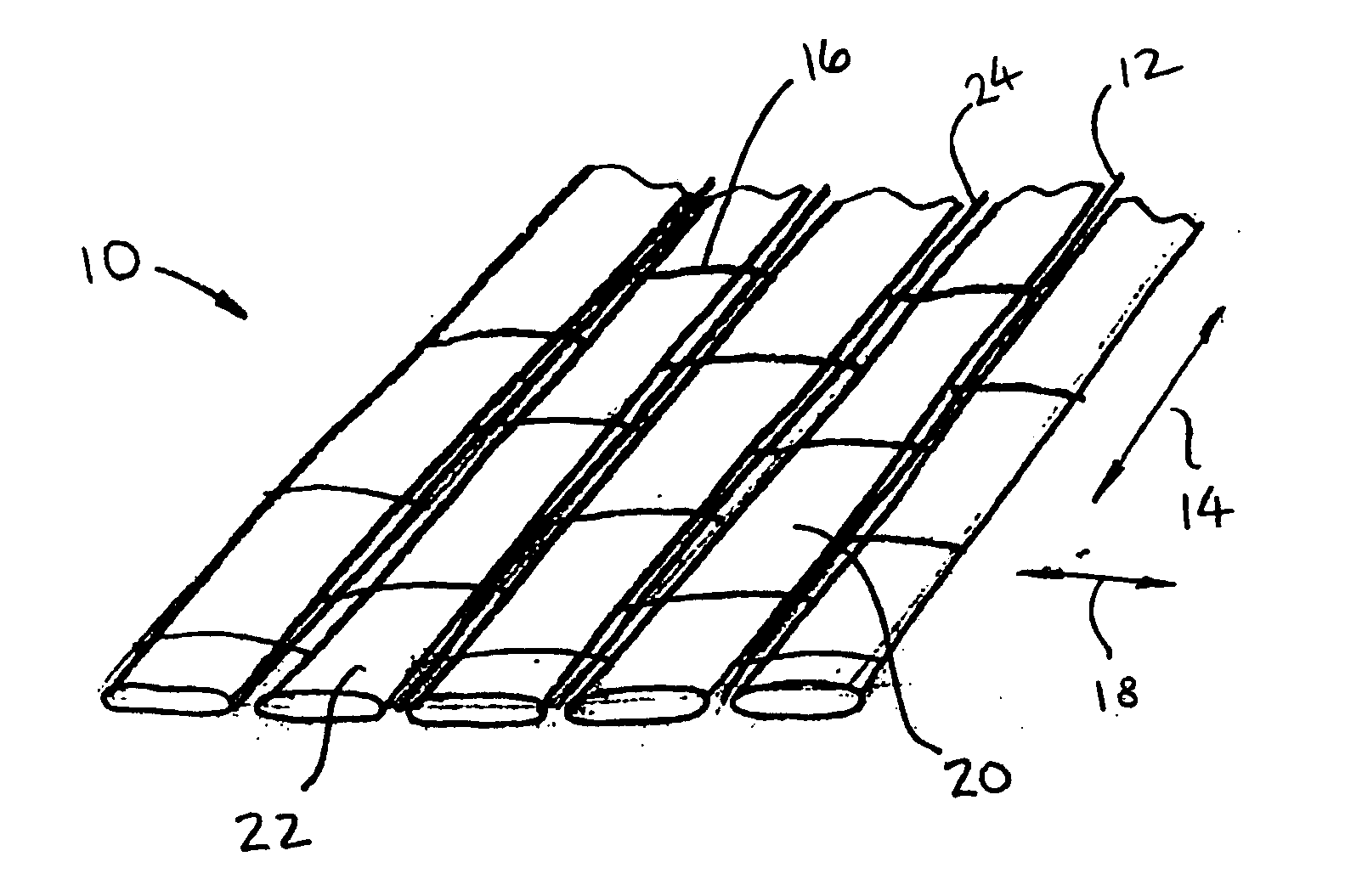

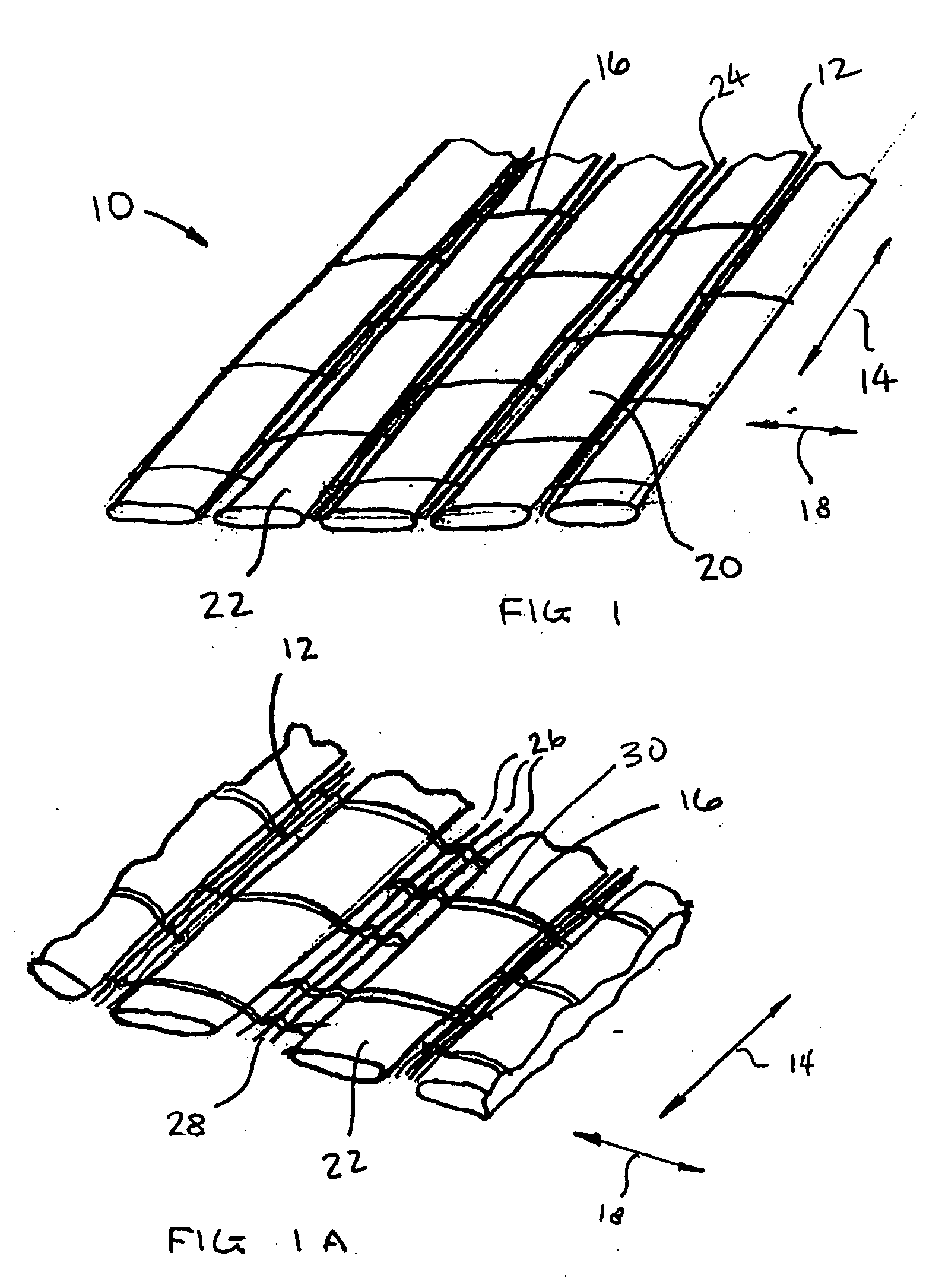

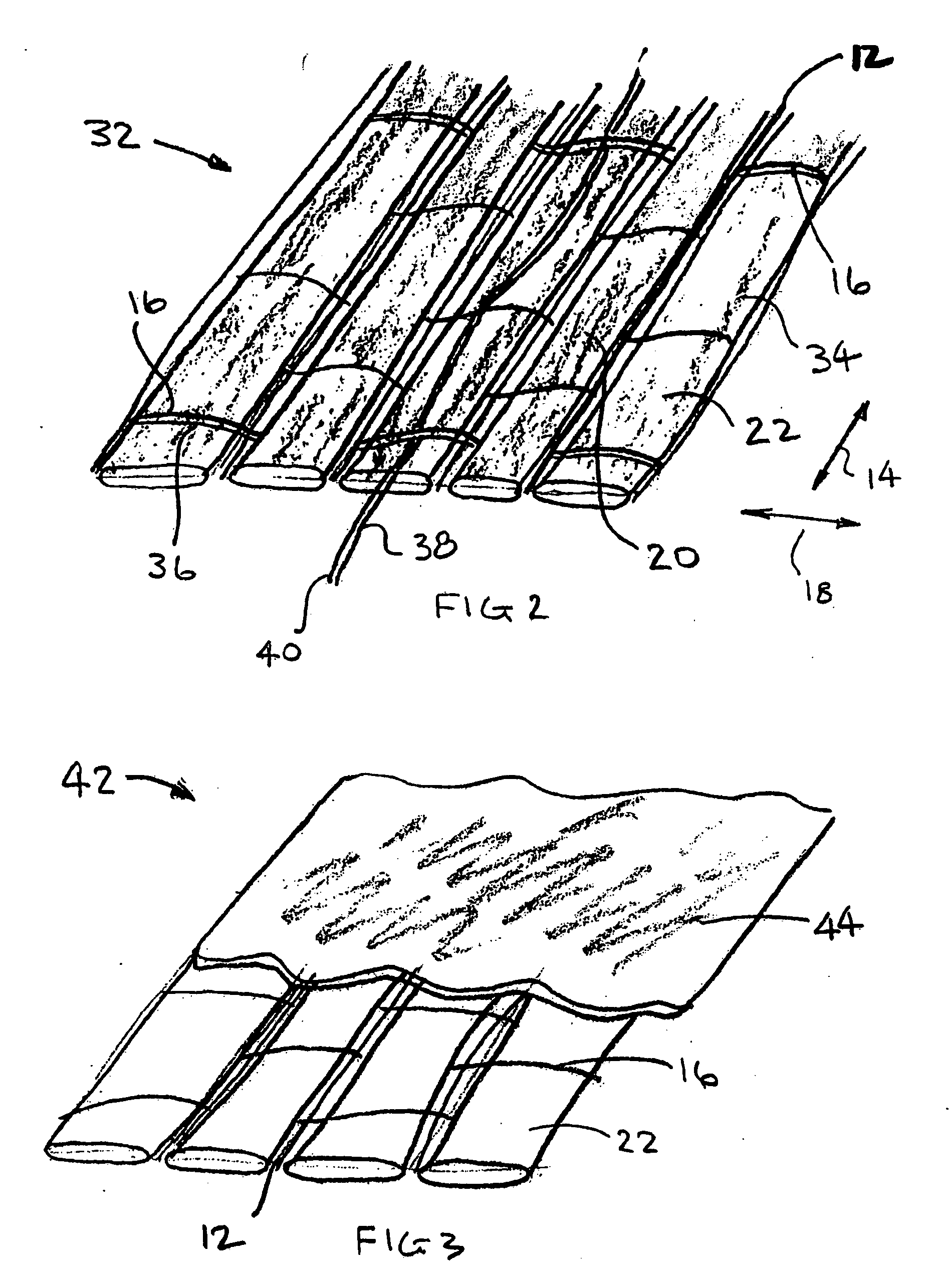

[0018]FIG. 1 shows a perspective view of a substrate according to the invention. Substrate 10 is formed from a plurality of first filamentary members 12 oriented in a first direction, indicated by arrow 14. For a woven substrate, the direction indicated by arrow 14 corresponds to the warp direction. Filamentary members 12 are interlaced with a plurality of second filamentary members 16. Second filamentary members 16 are oriented transversely to the first filamentary members as indicated by arrow 18. In a woven substrate, the direction indicated by arrow 18 corresponds to the weft or fill direction. First filamentary members 12 are positioned in spaced apart relation relative to one another, as are the second filamentary members 16, This results in relatively large interstices 20 being formed by the interlacing of the first and second filamentary members. Weaving is a preferred method for interlacing the filamentary members, although warp knitting is also feasible.

[0019] Substrate 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| circular shape | aaaaa | aaaaa |

| electrically conducting | aaaaa | aaaaa |

| electrically conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com