Novel method and special device for precisely processing titanium alloy joint prosthesis by curved-surface turbulence

An artificial joint and precision machining technology, which is applied in metal processing equipment, manufacturing tools, abrasives, etc., can solve the problems of low processing efficiency, low processing accuracy, uneven processing, etc., and achieve easy design and manufacture, reduce sewage discharge, The effect of improving abrasive grain utilization and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A new method for turbulent precision machining of titanium alloy artificial joint surface is to construct a restricted flow channel on the outer surface of the titanium alloy artificial joint prosthesis, flow abrasive grains into the restricted flow channel, and artificially control the titanium alloy in a turbulent state. The outer surface of the joint prosthesis is ground and polished.

[0016] The technical idea of the present invention is: abrasive grains with weak viscosity or non-viscosity flow through the flow channel and pass through the outer surface of the artificial joint prosthesis, and in the state of turbulent flow, the frequent action of micro-force and micro-cutting of the abrasive grains is used to realize surface roughness. Step by step smoothing, the randomness of the abrasive grain movement in the turbulent flow field realizes the disorder of the surface texture until the tool-free mirror-level processing of the artificial joint prosthesis surface i...

Embodiment 2

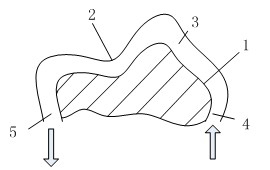

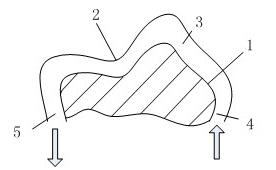

[0018] refer to figure 1 , a special device for a new method of turbulent precision machining of a titanium alloy artificial joint surface, including a titanium alloy artificial joint prosthesis 1, the outer surface of the titanium alloy artificial joint prosthesis 1 is covered with a titanium alloy artificial joint prosthesis matching model 2, the A restricted flow channel 3 is formed between the outer surface of the titanium alloy artificial joint prosthesis 1 and the inner surface of the titanium alloy artificial joint prosthesis matching model 2, and the inlet 4 of the restricted flow channel 3 is connected with a flow of abrasive particles. The outlet 5 of the pipeline is connected with the abrasive particle flow outflow pipeline.

[0019] The shape of the titanium alloy artificial joint prosthesis matching model 2 is the same as that of the titanium alloy artificial joint prosthesis 1, and the size of the titanium alloy artificial joint prosthesis matching model 2 is lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com