New method of silicon nanotube/ wire modified fiber surface

A technology for modifying fibers and silicon nanotubes, which is applied in fiber processing, textile and papermaking, physical processing, etc., can solve the problems of difficulty in controlling the uniformity of fiber surface bonding, reducing the performance and flexibility of the fiber body, and being difficult to industrialize. Achieve the effect of reducing chemical consumption and production cost, improving hydrolysis resistance, and increasing roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

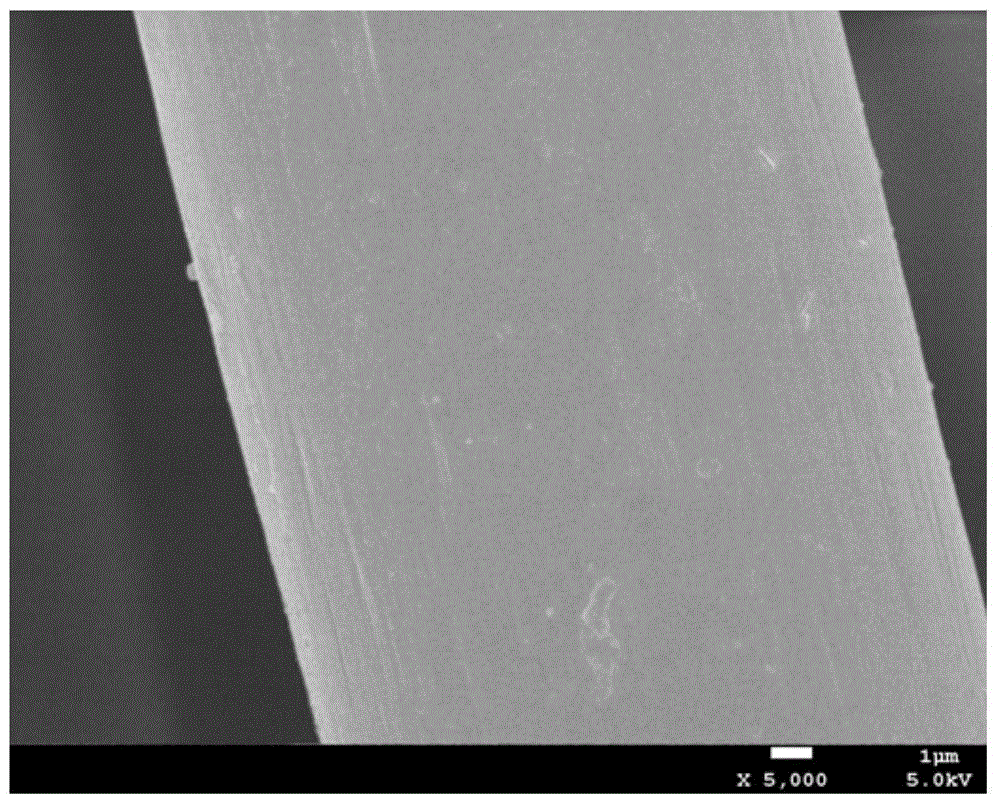

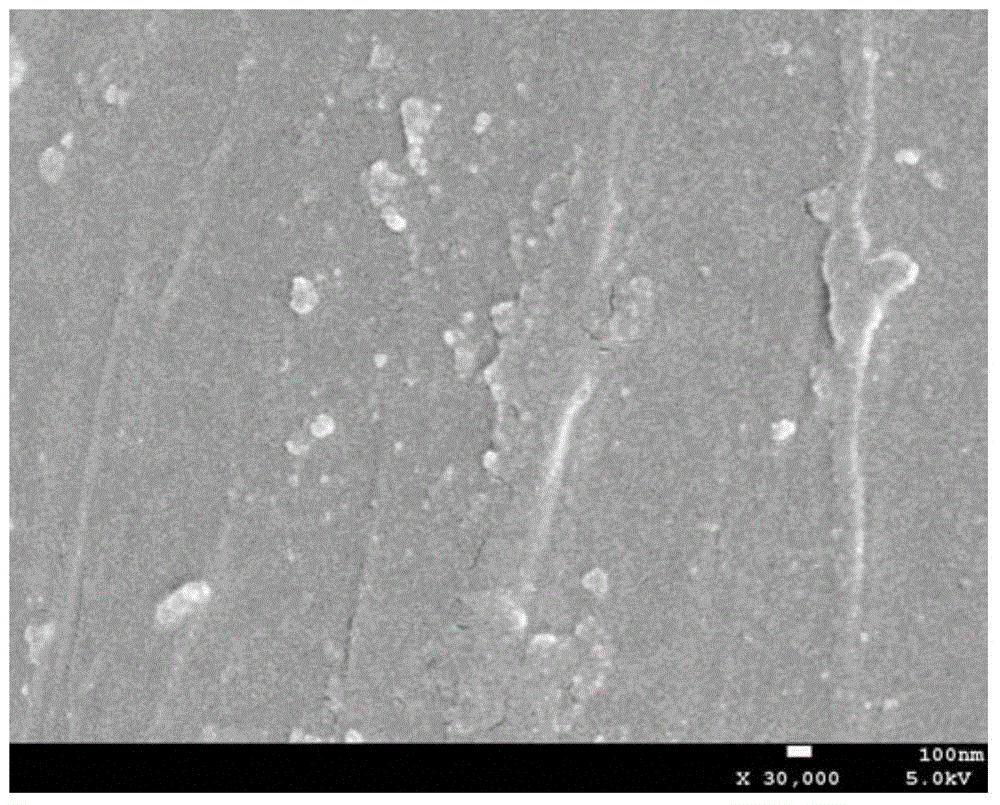

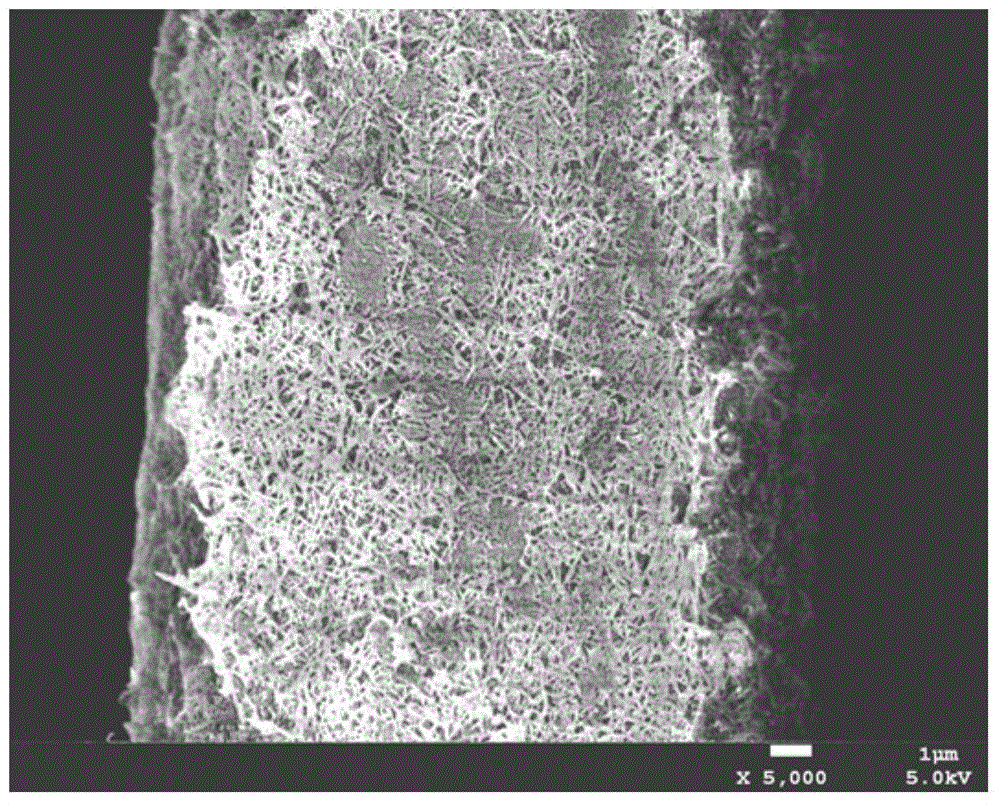

[0041] (1) Cleaning and drying of fibers: heat and reflux Kevlar49 fibers in acetone, petroleum ether and deionized water for 3 hours respectively, put the cleaned fibers in a vacuum drying oven, and dry them at 80°C for 12 hours. See the whole and part of figure 1 and figure 2 ;

[0042](2) Plasma treatment of fibers: place the fibers obtained in step (1) in a plasma generating device, and process them in an air atmosphere for 5 minutes under the condition of a power of 150W;

[0043] (3) Fiber modification: add 0.1ml methyltriethoxysilane in 90ml toluene, then add 0.6ml hydrochloric acid, stir to get 0.1% acidic methyltriethoxysilane toluene organic solution, the (2) Immerse the treated fibers in the prepared acidic silane organic solution, and stir for 7 hours at 30°C and 450rpm;

[0044] (4) Cleaning and drying of the modified fiber: The modified Kevlar49 fiber was washed with acetone, absolute ethanol and a large amount of deionized water respectively, and then put in...

Embodiment 2

[0047] (1) Cleaning and drying of fibers: Heat and reflux the glass fibers in acetone, petroleum ether and deionized water for 3 hours respectively, then place the cleaned fibers in a vacuum drying oven and dry them at 80°C for 12 hours, see Figure 5 ;

[0048] (2) Plasma treatment of fibers: place the fibers obtained in step (1) in a plasma generating device, and process them in an air atmosphere for 5 minutes under the condition of a power of 150W;

[0049] (3) Fiber modification: 1.2ml methyltriethoxysilane is added in 90ml toluene, then add 0.6ml hydrochloric acid, stir to obtain the toluene organic solution of 1.3% acidic methyltriethoxysilane. (2) Immerse the treated fibers in an acidic silane organic solution, and stir for 3 hours at 30°C and 450rpm;

[0050] (4) Cleaning and drying of the modified fiber: Wash the modified glass fiber with acetone, absolute ethanol and a large amount of deionized water respectively, put it in a vacuum drying oven after cleaning, and d...

Embodiment 3

[0052] (1) Cleaning and drying of fibers: heat and reflux the glass fibers in acetone, petroleum ether and deionized water for 3 hours respectively, then place the cleaned fibers in a vacuum drying oven and dry them at 80°C for 12 hours;

[0053] (2) Plasma treatment of fibers: place the fibers obtained in step (1) in a plasma generating device, and process them in an air atmosphere for 5 minutes under the condition of a power of 150W;

[0054] (3) Fiber modification: 1.2ml methyltriethoxysilane is added in 90ml toluene, then add 0.6ml hydrochloric acid, stir to obtain the toluene organic solution of 1.3% acidic methyltriethoxysilane. (2) Immerse the treated fibers in an acidic silane organic solution, and stir for 7 hours at 30°C and 450rpm;

[0055] Cleaning and drying of the modified fiber: Wash the modified glass fiber with acetone, absolute ethanol and a large amount of deionized water respectively, put it into a vacuum drying oven after cleaning, and dry it at 80°C for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com