Patterning growth method of single-walled carbon nanotubes by surface ruling method

A carbon nanotube and patterning technology, applied in the fields of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of reducing quality, increasing cost, affecting the intrinsic properties of single-wall carbon nanotubes, etc., achieving low cost and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

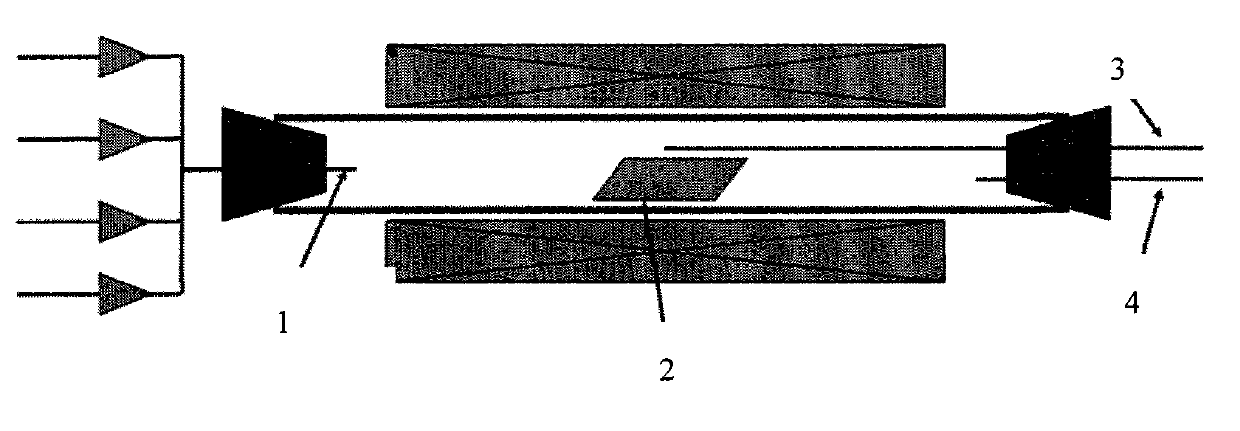

[0025] Such as figure 1 As shown, the device of the present invention adopts a horizontal reaction furnace, the two ends of the horizontal reaction furnace are respectively provided with a gas inlet 1 and a gas outlet 4, and the silicon chip 2 with a thermal oxidation layer is placed in the high temperature zone of the horizontal reaction furnace, and the thermocouple 3 Extend into the high temperature zone of the horizontal reactor to monitor the reaction temperature in real time.

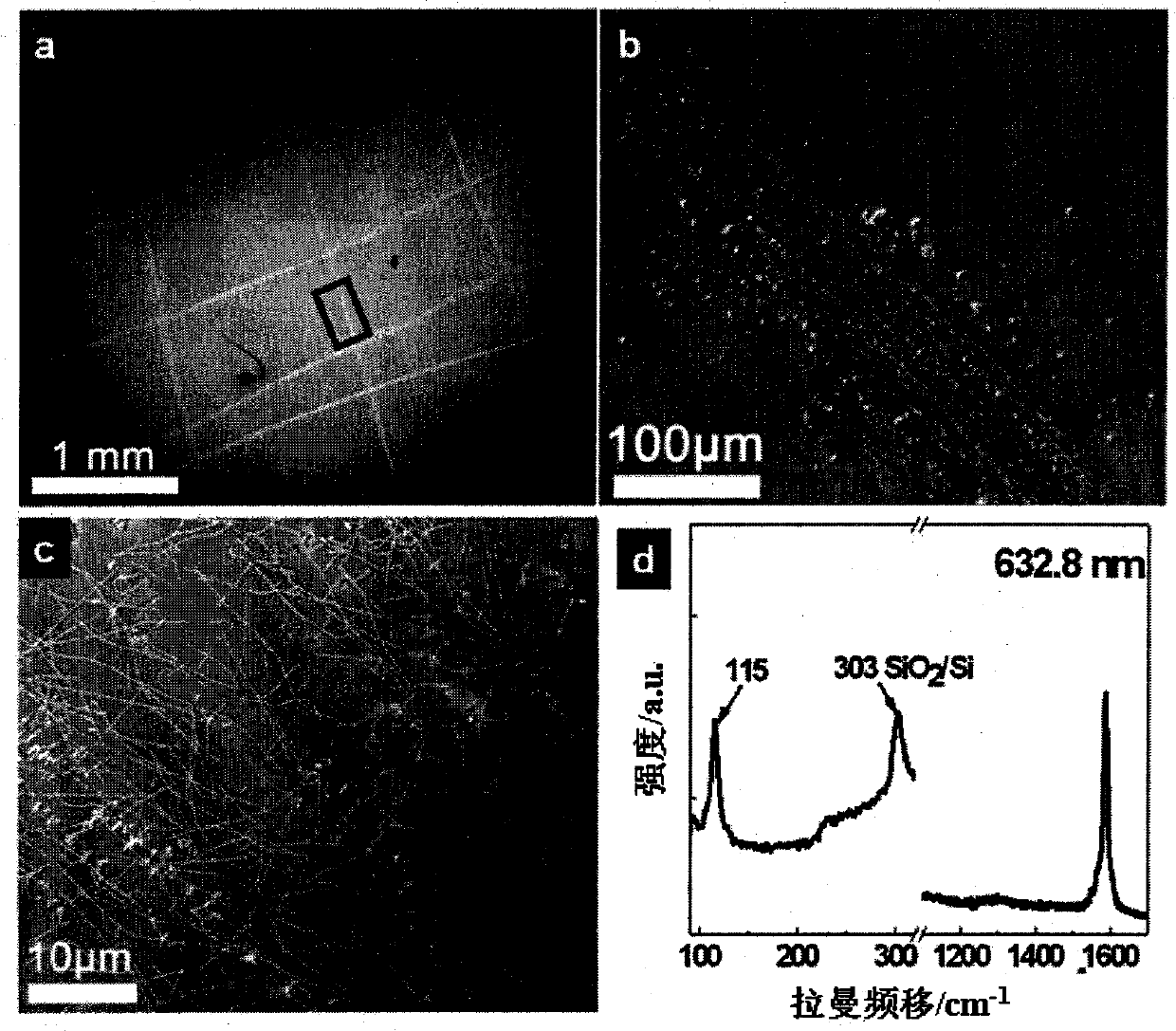

[0026] Silicon wafers with sharp corners are used to score the surface with thermally oxidized SiO 2 layer (10nm) of the silicon substrate to obtain a specific pattern. First, place the silicon substrate in the central area of a horizontal reaction furnace (reaction area, where a thermocouple monitors the furnace temperature in real time); heat it to 850°C in an oxygen atmosphere (the flow rate of oxygen during the heating process is 100 ml / min , heating rate is 40°C / min), oxidation heat treat...

Embodiment 2

[0029] device attached figure 1 .

[0030] Silicon wafers with sharp corners are used to score the surface with thermally oxidized SiO 2 layer (5nm) of the silicon substrate to obtain a specific pattern. First, place the silicon substrate in the central area of a horizontal reactor (reaction zone, where a thermocouple monitors the furnace temperature in real time); heat it to 850°C in an oxygen atmosphere (the oxygen flow rate during the heating process is 200 ml / min , heating rate is 30°C / min), oxidation heat treatment for 10 minutes; then, use 1000 ml / min of argon to exhaust for 8 minutes; (The gas flow rates are respectively 300 ml / min of methane and 500 ml / min of hydrogen), start to grow single-walled carbon nanotubes, and the growth time is 20 minutes.

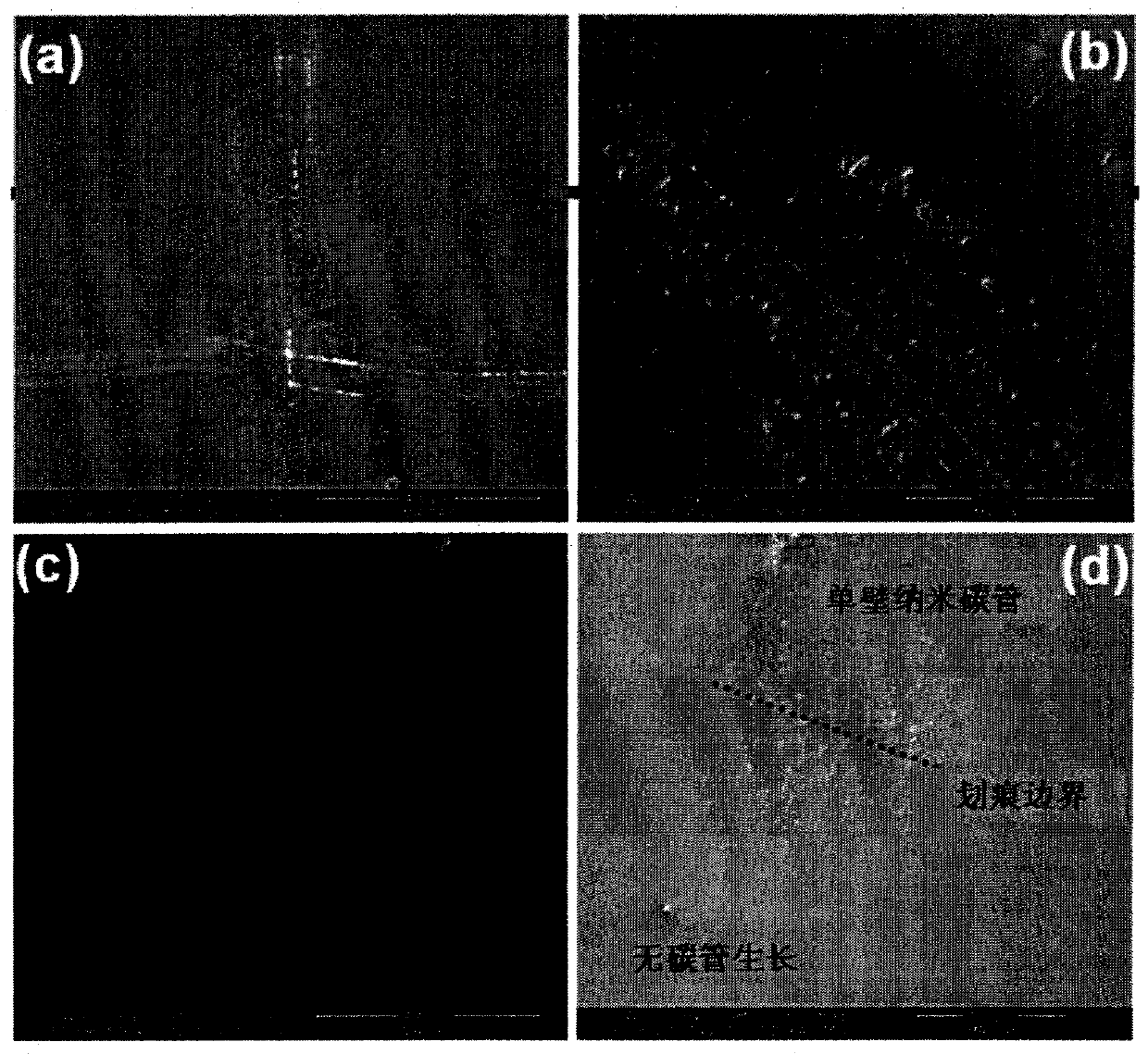

[0031] Scanning electron microscopy, atomic force microscopy and resonance laser Raman spectroscopy observations show that only the scratched area has single-walled carbon nanotubes, which is a randomly distributed n...

Embodiment 3

[0033] device attached figure 1 .

[0034] Silicon wafers with sharp corners are used to score the surface with thermally oxidized SiO 2 layer (10nm) of the silicon substrate to obtain a specific pattern. First, place the silicon substrate in the central area of a horizontal reaction furnace (reaction area, where a thermocouple monitors the furnace temperature in real time); heat it to 850°C in an oxygen atmosphere (the flow rate of oxygen during the heating process is 100 ml / min , heating rate is 40°C / min), oxidative heat treatment for 10 minutes; then, 1000 ml / min of argon gas is used for 8 minutes; into ethanol (wherein, the flow rate of argon is 200 ml / min, and the ethanol is placed in a Montessori washing bottle with a constant temperature of 0 ℃), and hydrogen is introduced as a buffer gas (gas flow rate is 500 ml / min) at the same time, and the growth of single cells is started. Wall carbon nanotubes, the growth time is 20 minutes.

[0035] Scanning electron micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com