Biological chip and preparation method thereof

A biochip and polymer technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problems of easy deformation or denaturation, poor resistance to physical and chemical forces, poor long-term anti-adhesive effect, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0155] Also, see Figure 6 , the preparation method of the above-mentioned biochip according to one embodiment, comprising the following steps S110-S120.

[0156] S110, providing a substrate.

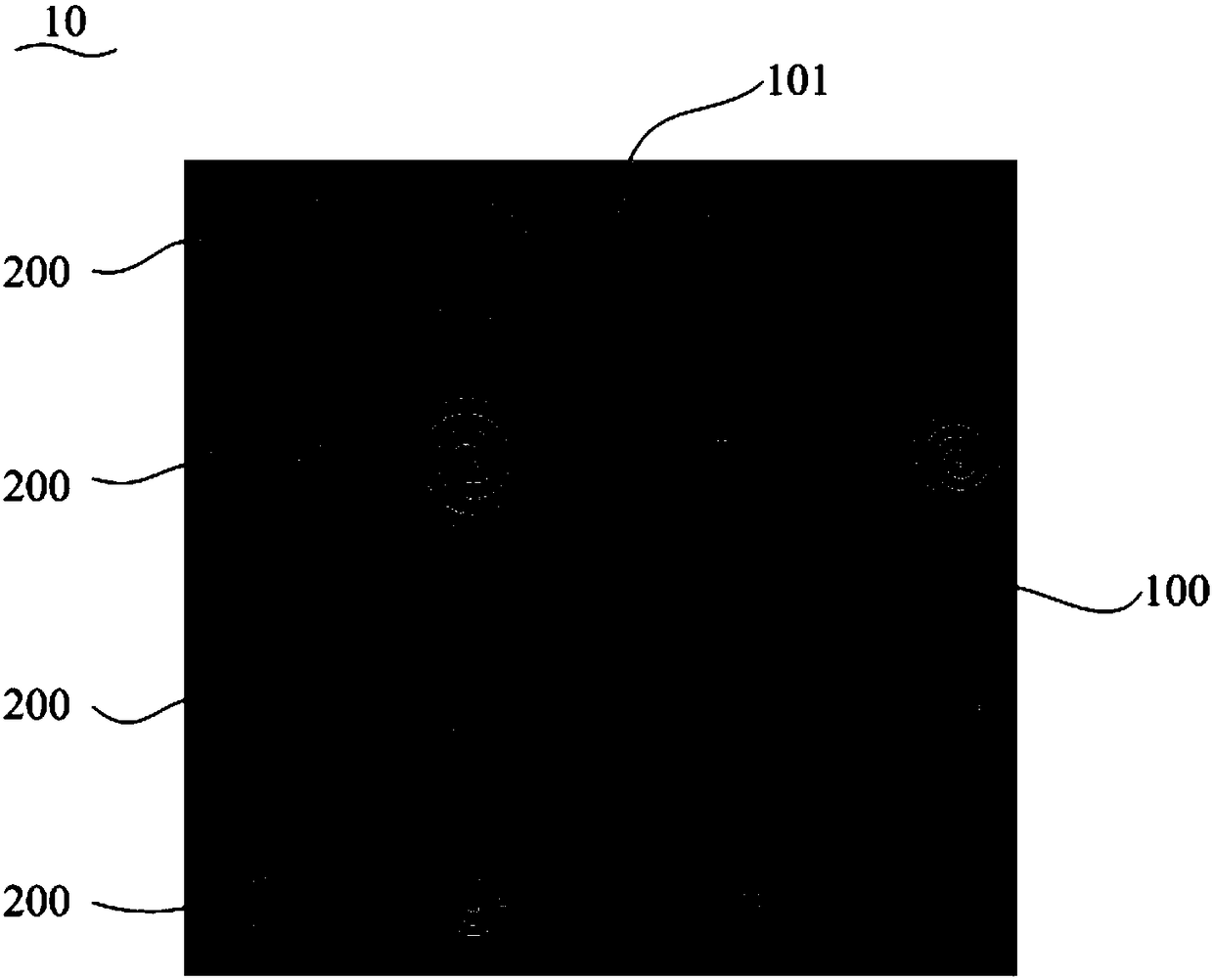

[0157] In one embodiment, the structure of the prefabricated biochip can be found in figure 1 , the substrate is an anti-adhesive substrate. The substrate is formed of an anti-adhesive material that resists cell adhesion, and the anti-adhesive material is zinc, magnesium, zinc alloy or magnesium alloy. Specifically, the substrate is, for example, a zinc plate, a magnesium plate, a zinc alloy plate or a magnesium alloy plate. The surface of the zinc plate, magnesium plate, zinc alloy plate or magnesium alloy plate is the anti-adhesive surface.

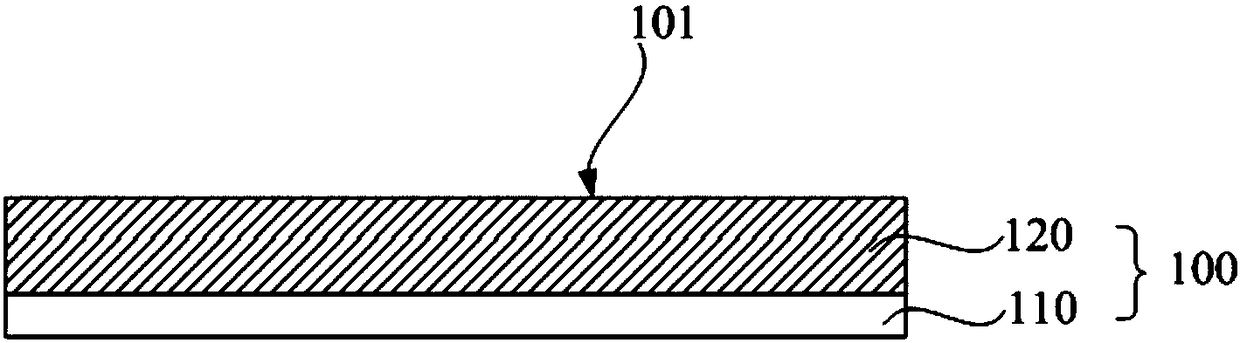

[0158] Alternatively, the base includes a substrate and an anti-sticking layer formed on the substrate, and the material of the anti-sticking layer is zinc, magnesium, zinc alloy or magnesium alloy. The substrate is, for example, a glass or ...

Embodiment 1

[0203] A zinc-magnesium alloy substrate with a thickness of 1mm (the mass percent of magnesium in the zinc alloy is 5%) is polished and pickled in a polishing solution. Specifically, the metal is immersed in the pickling solution, and the solvent of the pickling solution is Water, containing sulfuric acid (mass fraction concentration is 98%) 250mL / L, hydrochloric acid (mass fraction concentration is 37%) 20mL / L, nitric acid (mass fraction concentration is 68%) 20mL / L, pickling temperature is 25 ℃, time 5 to 100 seconds, and the final roughness of the anti-adhesive surface is 1 μm or less. Then placed in acetone, ultrasonicated three times, blown dry with nitrogen and baked at 120°C for 8 hours to make the anti-adhesive surface hydrophobic. Take it out and cool it down to room temperature, and spin-coat photoresist (Suzhou Ruihong, RZJ-3038) on its surface in a darkroom clean room. The substrate after homogenization was placed in an oven at 100°C for 20 minutes. Take it out a...

Embodiment 2

[0205] The zinc substrate with a thickness of 1 mm was polished and pickled in oxalic acid to remove surface impurities and make the anti-adhesive surface roughness 1 μm. Then placed in acetone, ultrasonicated three times, blown dry with nitrogen and baked at 110°C for 8 hours to make the anti-adhesive surface hydrophobic. According to the steps in Example 1, a gold micron pattern was prepared on a zinc-magnesium alloy substrate, and then a c-(RGD-fK)-SH (sulfhydryl group modified on RGD peptide) solution with a concentration of 25 μM was prepared and added dropwise to the gold micron pattern on the surface of the substrate. On patterning, a biochip with RGD micro-patterns that can selectively adhere to cells was obtained. In addition, RGD (arginine-glycine-aspartic acid) peptide, RGD peptide derivative (cyclic arginine-glycine-aspartic acid-phenylalanine-lysine Polypeptides—c-(RGD)-fK), YIGSR (tyrosine-isoleucine-glycine-serine-arginine polypeptides), RGD polypeptides, YIGSR...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com