Biochip and its preparation method

A biochip and polymer technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the limitation of application range, the inability to maintain long-term selective adhesion of cell adhesion patterns, easy deformation or denaturation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

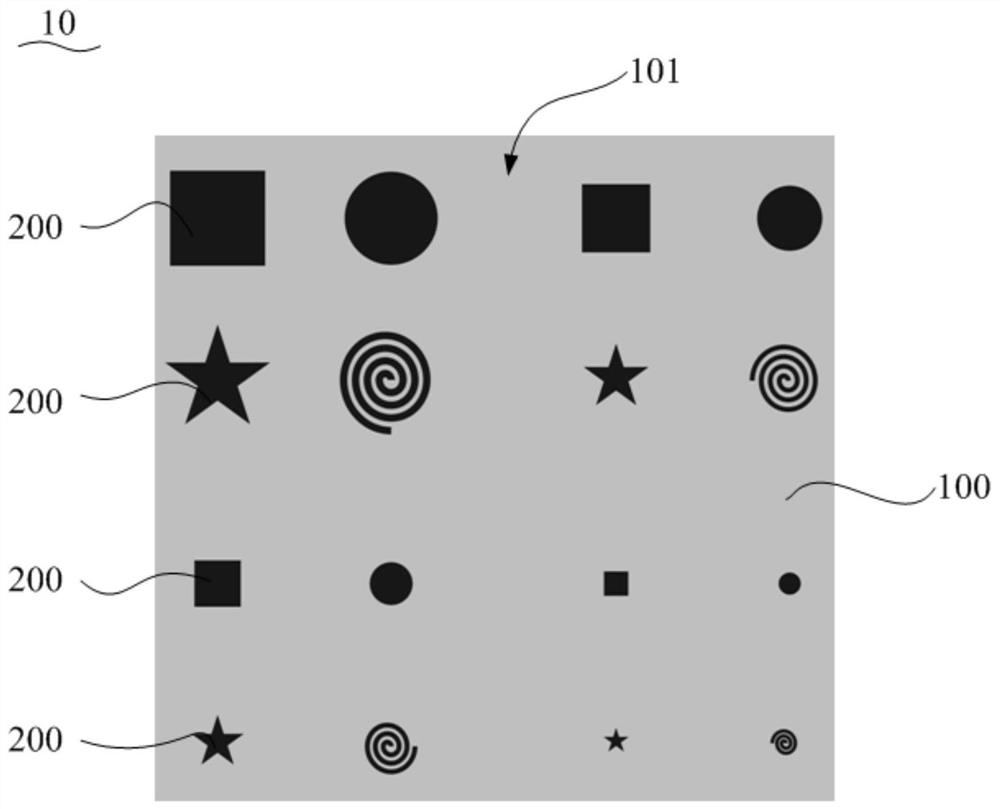

[0155] Also, see Image 6 , the preparation method of the above-mentioned biochip according to one embodiment, comprising the following steps S110-S120.

[0156] S110, providing a substrate.

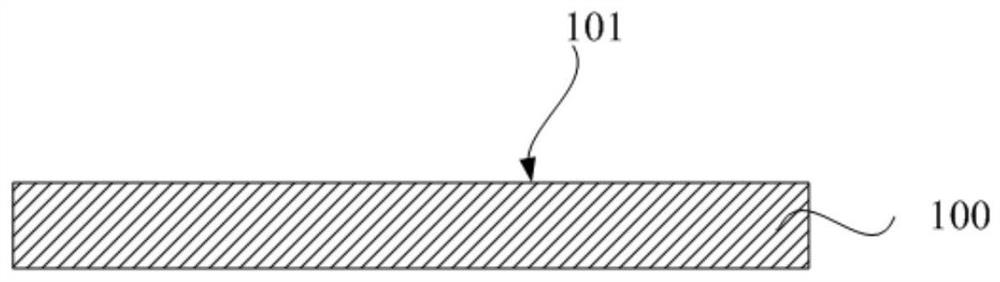

[0157] In one embodiment, the structure of the prefabricated biochip can be found in figure 1 , the substrate is an anti-adhesive substrate. The substrate is formed of an anti-adhesive material that resists cell adhesion, and the anti-adhesive material is zinc, magnesium, zinc alloy or magnesium alloy. Specifically, the substrate is, for example, a zinc plate, a magnesium plate, a zinc alloy plate or a magnesium alloy plate. The surface of the zinc plate, magnesium plate, zinc alloy plate or magnesium alloy plate is the anti-adhesive surface.

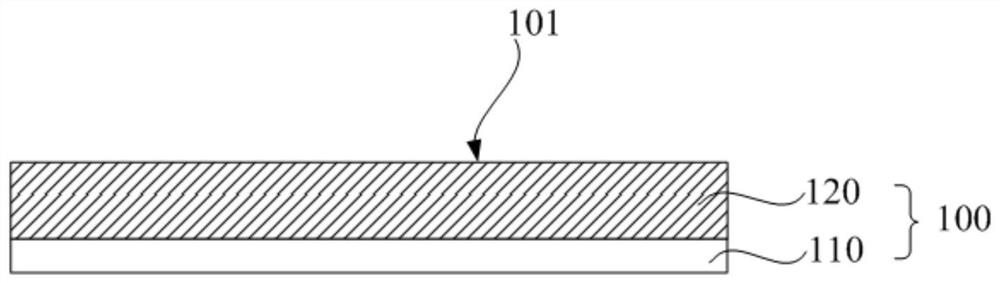

[0158] Alternatively, the base includes a substrate and an anti-sticking layer formed on the substrate, and the material of the anti-sticking layer is zinc, magnesium, zinc alloy or magnesium alloy. The substrate is, for example, a glass or a...

Embodiment 1

[0203] A zinc-magnesium alloy substrate with a thickness of 1mm (the mass percent of magnesium in the zinc alloy is 5%) is polished and pickled in a polishing solution. Specifically, the metal is immersed in the pickling solution, and the solvent of the pickling solution is Water, containing sulfuric acid (mass fraction concentration is 98%) 250mL / L, hydrochloric acid (mass fraction concentration is 37%) 20mL / L, nitric acid (mass fraction concentration is 68%) 20mL / L, pickling temperature is 25 ℃, time 5 to 100 seconds, and the final roughness of the anti-adhesive surface is 1 μm or less. Then placed in acetone, ultrasonicated three times, blown dry with nitrogen and baked at 120°C for 8 hours to make the anti-adhesive surface hydrophobic. Take it out and cool it down to room temperature, and spin-coat photoresist (Suzhou Ruihong, RZJ-3038) on its surface in a darkroom clean room. The substrate after homogenization was placed in an oven at 100°C for 20 minutes. Take it out a...

Embodiment 2

[0205] The zinc substrate with a thickness of 1 mm was polished and pickled in oxalic acid to remove surface impurities and make the anti-adhesive surface roughness 1 μm. Then placed in acetone, ultrasonicated three times, blown dry with nitrogen and baked at 110°C for 8 hours to make the anti-adhesive surface hydrophobic. According to the steps in Example 1, a gold micron pattern was prepared on a zinc-magnesium alloy substrate, and then a c-(RGD-fK)-SH (sulfhydryl group modified on RGD peptide) solution with a concentration of 25 μM was prepared and added dropwise to the gold micron pattern on the surface of the substrate. On patterning, a biochip with RGD micro-patterns that can selectively adhere to cells was obtained. In addition, RGD (arginine-glycine-aspartic acid) peptide, RGD peptide derivative (cyclic arginine-glycine-aspartic acid-phenylalanine-lysine Polypeptides—c-(RGD)-fK), YIGSR (tyrosine-isoleucine-glycine-serine-arginine polypeptides), RGD polypeptides, YIGSR...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com