Applicable method for growing patterned ZnO nanostructures on different substrates

A technology of zinc oxide nano and zinc oxide nanorods, which is applied in the field of nanomaterials, can solve the problems of lack of space controllability, difficulty in patterned growth, etc., and achieve the effect of patterned growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

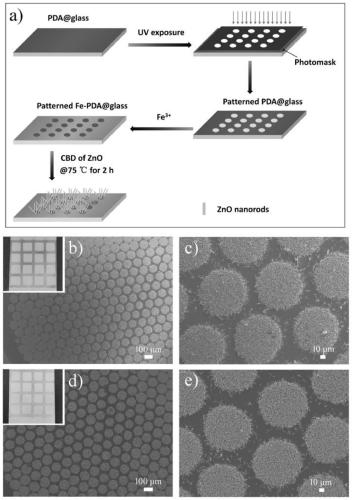

[0033] (1) Preparation of polydopamine film:

[0034] Method 1: Submerge the substrate in the dopamine solution for 10-30 minutes, take it out and rinse it with water for the second time, repeat the same soaking operation several times, and finally rinse it with water for the second time, and dry it with nitrogen. The dopamine solution uses a pH of 6-9 Tris-hydrochloric acid buffer solution preparation, the dopamine concentration is 0.1-10mg / mL;

[0035] Method 2: Submerge the substrate in a dopamine solution for 1 to 12 hours. The dopamine solution is prepared as follows: dopamine is dissolved in a tris-hydrochloric acid buffer solution with a pH of 8.5, and the concentration of dopamine is 2 mg / mL.

[0036] (2) Iron ions activate different substrates:

[0037] Prepare FeCl 3 Fresh solution (concentration 10mM-0.01nM), put different substrates into the solution and soak for 15-120 minutes, take it out, wash it with water twice, and dry it with nitrogen gas. This method ref...

Embodiment 1

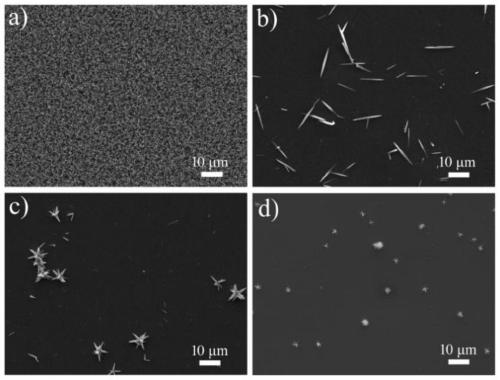

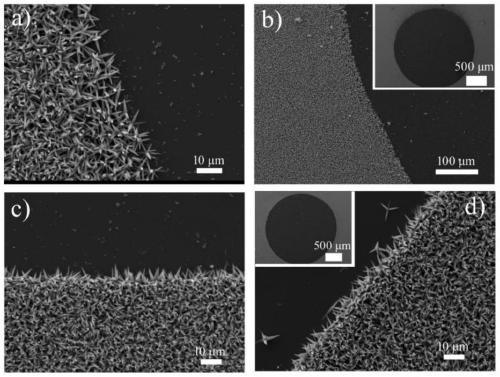

[0047] Example 1 Growth of zinc oxide nanostructures on glass slides (direct growth of zinc oxide nanostructures after iron ion activation)

[0048] The specific steps are:

[0049] 1) Activate iron ions on the substrate: prepare FeCl with a concentration of 5mM 3 Fresh solution, put the substrate into the solution and soak for 15-120 minutes, take it out, wash it with water twice, and dry it with nitrogen. This method refers to J.Mater.Chem., 2009, 19, 3847 and Chem.Mater., 2008, 20,4542;

[0050]2) Growth of zinc oxide nanorods by wet chemical method: growth of randomly oriented zinc oxide nanorods refers to J.Mater.Chem., 2009, 19, 3847 and Chem.Mater., 2008, 20, 4542, and the configuration contains Zn(NO 3 ) 2 ·6H 2 A solution of O (0.1M), 3% (v / v) ammonia water (28wt%), 1% (v / v) ethylenediamine (≥99%) and 97mL deionized water, insert the substrate vertically into the solution, water bath Heat to 75°C for 2 hours, take out the substrate, rinse with tap water, and blow...

Embodiment 2

[0051] Example 2 Growth of zinc oxide nanostructures on glass slides (direct growth of zinc oxide nanostructures after preparing polydopamine film)

[0052] The specific steps are:

[0053] 1) Prepare a polydopamine film on the surface of an inert substrate: immerse the glass slide in the dopamine solution for 10-30 minutes, rinse it with water twice after taking it out, repeat the same soaking operation 5 times, and finally rinse it with water twice, and dry it with nitrogen. The dopamine solution was prepared by tris-hydrochloric acid buffer solution with a pH of 8.5, and the dopamine concentration was 1 mg / mL.

[0054] 2) Step 2) is consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com