Industrial equipment vibration characteristic value trend prediction method based on data model

A technology of industrial equipment and data models, applied in the direction of electrical digital data processing, special data processing applications, measuring devices, etc., can solve problems affecting network approximation ability and promotion properties, fault tolerance decline, low network performance, etc., and achieve access to Simple, easy to calculate, obtain efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is further described below in conjunction with accompanying drawing:

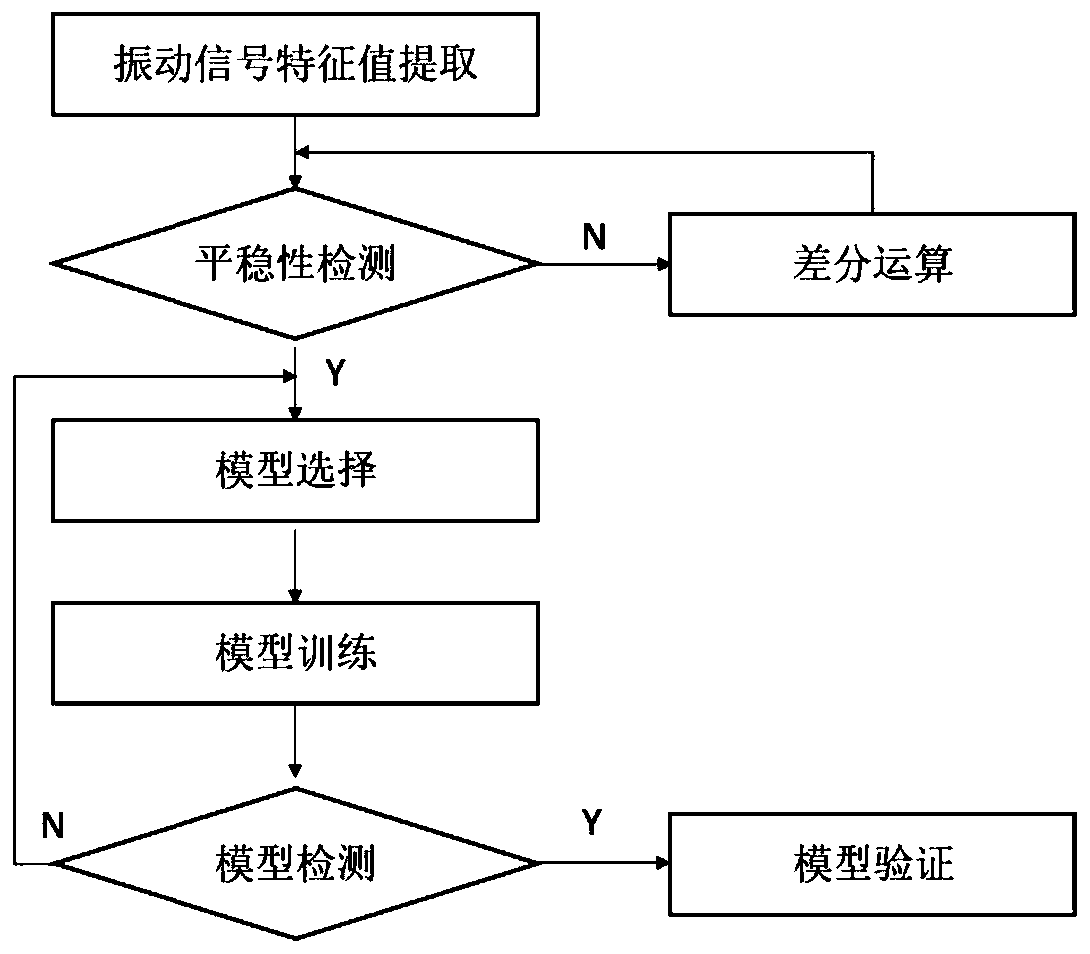

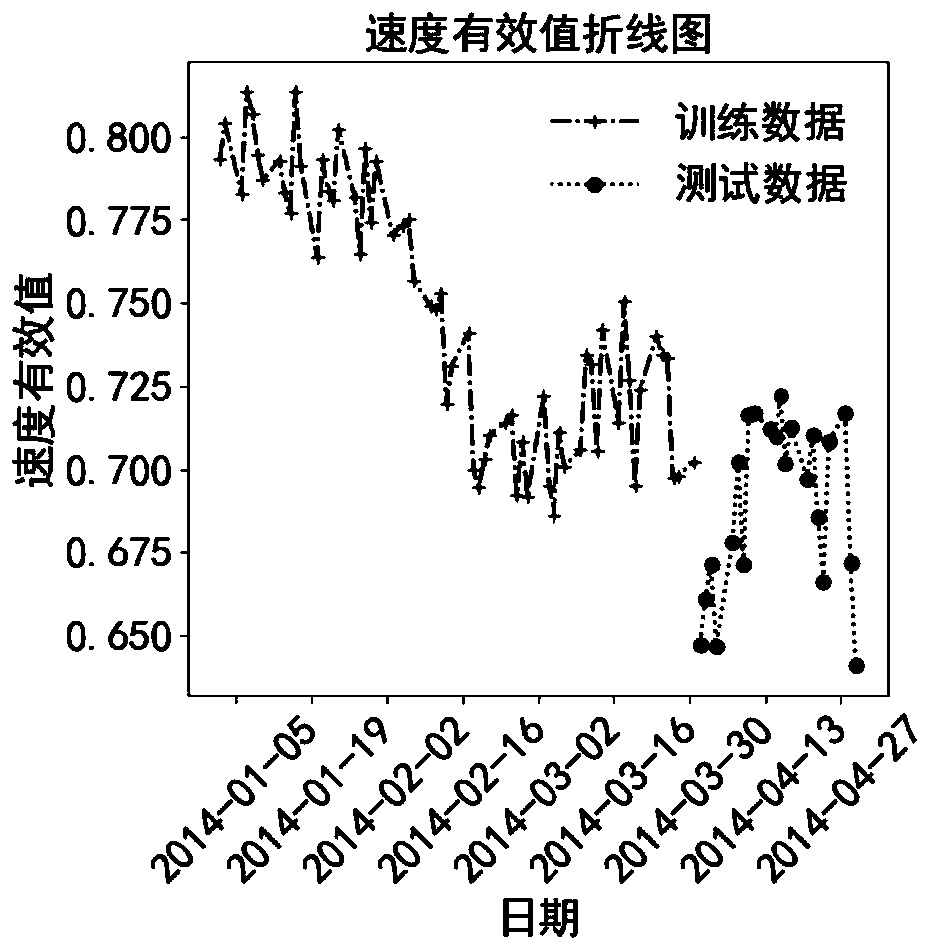

[0050] see Figure 1 to Figure 7 : (1) Select a certain industrial equipment and install a vibration sensor on the equipment to collect the characteristic values of acceleration, velocity, displacement and envelope signals. By selecting the historical data and current data of vibration characteristic values, a group with chronological data sequence {T 0 ,T 1 ,...,T n}. Historical data as training data {T 0 ,T 1 ,...,T m}, the current data as test data {T m+1 ,T m+2 ,...,T n}.

[0051] (2) Observe the training data {T 0 ,T 1 ,...,T m}, if it is not stable, perform the first-order difference operation, and then observe the stationarity to decide whether to continue the difference until the non-stationary trend of the training data sequence is eliminated. The calculation formula of difference operation is:

[0052] T' t =T t+1 -T t

[0053] where T' t is the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com