Synthetic method for size-controllable silicon nanotubes for lithium ion batteries

A lithium-ion battery, silicon nanotube technology, applied in nanotechnology, nanotechnology, silicon compounds and other directions for materials and surface science, can solve the problem that the aspect ratio and thickness are difficult to effectively control, and the size of the hydrothermal method is difficult to synthesize. Controllability, can not well reflect the characteristics of silicon nanotubes, etc., to achieve the effect of improving the volume expansion effect, regulating the wall thickness, and solving the volume expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: a kind of synthetic method that is used for lithium-ion battery size thyristor nanotube, comprises the steps:

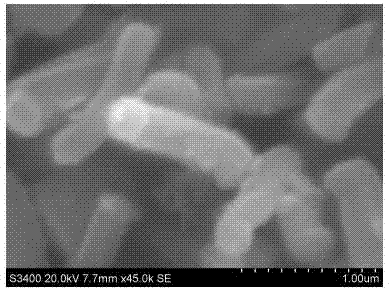

[0033] (1) Preparation of mesoporous silica nanorods: 6 parts of ethyl orthosilicate, 1.3 parts of cetyltrimethylammonium bromide, 0.2 parts of polyethylene glycol-4000, 6 parts of ammonia water, 92.5 parts of pure water Parts were magnetically stirred at 28°C for 18 hours, centrifuged, and dried to obtain mesoporous silica nanorods with a diameter of 200-500nm and a length of 1-4um;

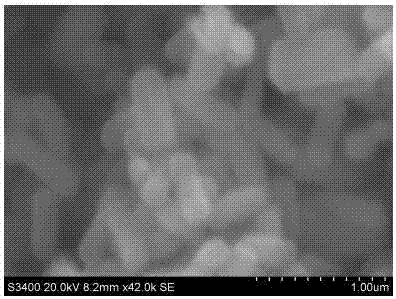

[0034] (2) Mesoporous silica nanorods are etched into tubes: Disperse 2 parts by mass of mesoporous silica nanorods in 96.5 parts by mass of pure water, add 0.7 parts by mass of a surface-protecting For polyethyleneimine with effect and etching effect, heat to 120°C, stir magnetically for 5 hours, and let it stand for 4 hours; centrifuge, wash, and vacuum dry to constant weight to obtain silica nanotubes;

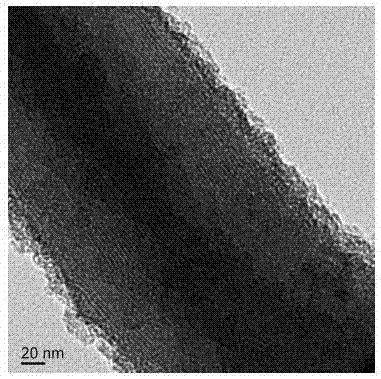

[0035] (3) Silica nanotubes are reduced to silicon nanotu...

Embodiment 2

[0036] Embodiment 2: a kind of synthetic method that is used for lithium-ion battery size thyristor nanotube, comprises the steps:

[0037] (1) Preparation of mesoporous silica nanorods: 2 parts of ethyl orthosilicate, 0.5 parts of cetyltrimethylammonium bromide, 0.1 part of polyoxyethylene polyoxypropylene ether block copolymer, 3 parts of ammonia water Parts, 90 parts of pure water, magnetically stirred at 20°C for 24 hours, centrifuged, and dried to obtain mesoporous silica nanorods with a diameter of 200-500nm and a length of 1-4um;

[0038] (2) Mesoporous silica nanorods are etched into tubes: Disperse 1 part by mass of mesoporous silica nanorods in 95 parts by mass of pure water, and add 1 part by mass of mesoporous silica nanorods with surface protection For polyethyleneimine with effect and etching effect, heat to 90°C, stir magnetically for 2 hours, and let it stand for 2 hours; centrifuge, wash, and vacuum dry to constant weight to obtain silica nanotubes;

[0039] ...

Embodiment 3

[0040] Embodiment 3: a kind of synthetic method that is used for lithium-ion battery size thyristor nanotube, comprises the steps:

[0041] (1) Preparation of mesoporous silica nanorods: 4 parts of ethyl orthosilicate, 0.9 parts of cetyltrimethylammonium bromide, 0.15 parts of polyethylene glycol-4000, 5 parts of ammonia water, 91.5 parts of pure water Magnetic stirring at 25°C for 24 hours, centrifugation, and drying to obtain mesoporous silica nanorods with a diameter of 200-500nm and a length of 1-4um;

[0042] (2) Mesoporous silica nanorods are etched into tubes: Disperse 1.5 parts by mass of mesoporous silica nanorods in 96 parts by mass of pure water, and add 0.6 parts by mass of a surface-protecting For polyethyleneimine with effect and etching effect, heat to 110°C, stir magnetically for 12 hours, and let stand for 8 hours; centrifuge, wash, and vacuum dry to constant weight to obtain silica nanotubes;

[0043] (3) Reduction of silica nanotubes to silicon nanotubes: p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com