A negative electrode binder and a method for preparing a silicon-based negative electrode sheet containing the binder

A binder and negative electrode technology, applied in the direction of negative electrodes, structural parts, battery electrodes, etc., can solve the problems of battery capacity attenuation, loss of electrical contact, damage to electrode structure, etc., to buffer volume expansion effect, improve adhesion, Effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

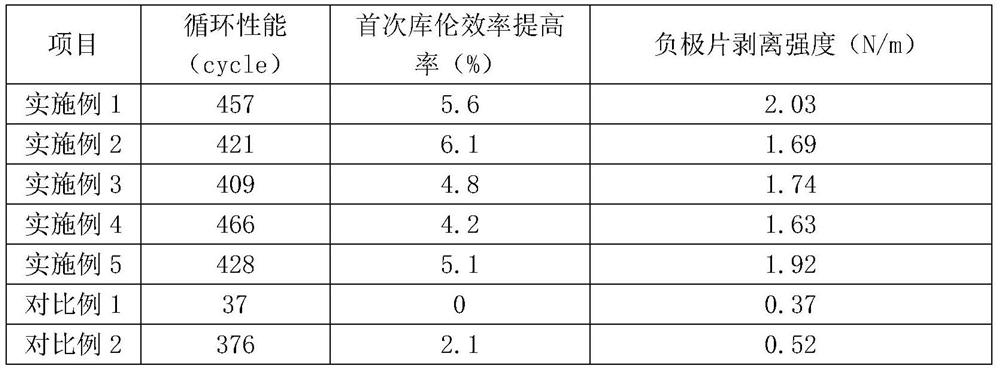

Examples

preparation example Construction

[0027] A negative binder of the present invention, prepared by the following method:

[0028] (1) The guar bean gum is dissolved in ethanol solution for dispersion, wherein the guar bean gum and the ethanol solution mass ratio of 1:3.3 ~ 5, to give the guar bean gum dispersion, to the guar bean gum dispersion liquid added cellulose ether, the cellulose ether and the quality ratio of the guar bean gum used is 0.2 ~ 0.6: 1, at 40 ~ 60 ° C reaction 30 ~ 60min, to give guar bean gum mixed solution;

[0029] (2) The guar bean gum mixed solution and functional monomers are mixed and stirred and placed under γ rays for irradiation, the dose rate of irradiation is 1~ 2.5kGy / h, the time is 12 ~ 24h, the irradiation product is washed, wherein the functional monomer is acrylic acid, 2-ethylacrylic acid, 2-propylacrylic acid, 2-butylacrylic acid at least one; Wherein the amount of functional monomer added is 1 to 5% of the amount of guar soybean gum used in step (1);

[0030] (3) The irradiat...

Embodiment 1

[0036] Preparation of negative binders:

[0037] (1) The guar bean gum is dissolved in ethanol solution for dispersion, wherein the guar gum and the mass ratio of the ethanol solution is 1:3.3, to obtain a guar bean gum dispersion, to the guar bean gum dispersion was added to the cellulose ether, the cellulose ether and the quality ratio of the guar bean gum used is 0.4:1, react at 60 ° C for 45min, to give a guar bean gum mixed solution;

[0038] (2) The guar bean gum mixed solution was mixed with acrylic acid for 10 min and then placed under γ radiation for irradiation, the dose rate of irradiation was 1kGy / h, the time was 24h, and the irradiation product was washed; Wherein the amount of acrylic acid is 1% of the amount of guar gum used in step (1);

[0039] (3) The irradiation product obtained after washing is mixed and stirred with sodium tetraborate, and the reaction is 30min to obtain a negative electrode binder.

[0040] Silicon-based negative electrode sheet prepared by t...

Embodiment 2

[0045] Preparation of negative binders:

[0046] (1) The guar bean gum is dissolved in ethanol solution for dispersion, wherein the guar bean gum and the ethanol solution mass ratio is 1:4, to obtain a guar bean gum dispersion, to the guar bean gum dispersion was added to the cellulose ether, the cellulose ether and the quality ratio of the guar bean gum used is 0.3:1, reacted at 50 ° C for 50min, to give a guar bean gum mixed solution;

[0047] (2) The guar bean gum mixed solution and methacrylic acid were mixed and stirred for 10 min and then placed under γ radiation for irradiation, the dose rate of irradiation was 1.5kGy / h, the time was 16h, and the irradiation products were washed; Wherein the amount of methacrylic acid added is 5% of the amount of guar gum used in step (1);

[0048] (3) The resulting product of the irradiation that has been washed is mixed and stirred with sodium tetraborate, and the reaction is 40min to obtain a negative binder.

[0049] Silicon-based negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com