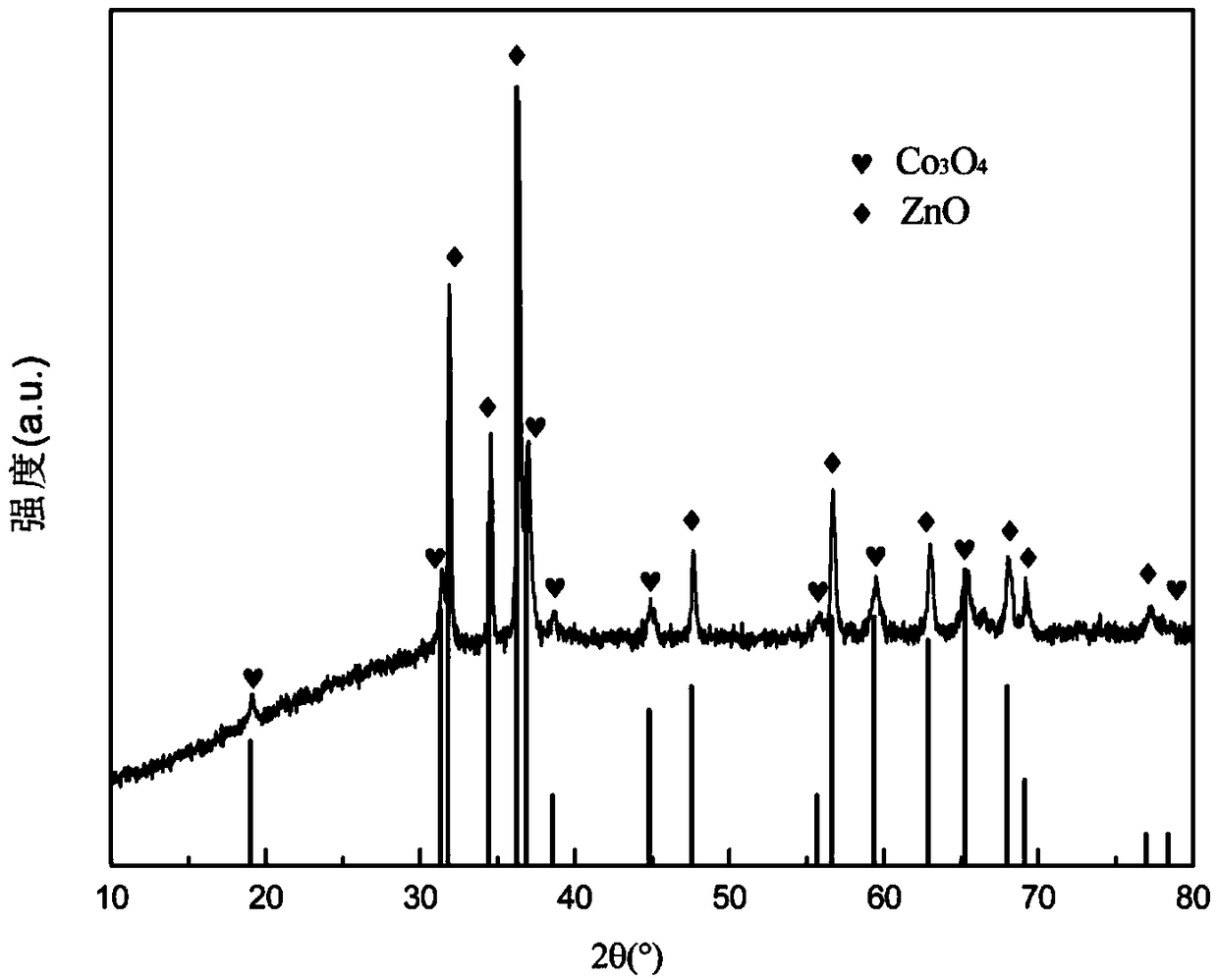

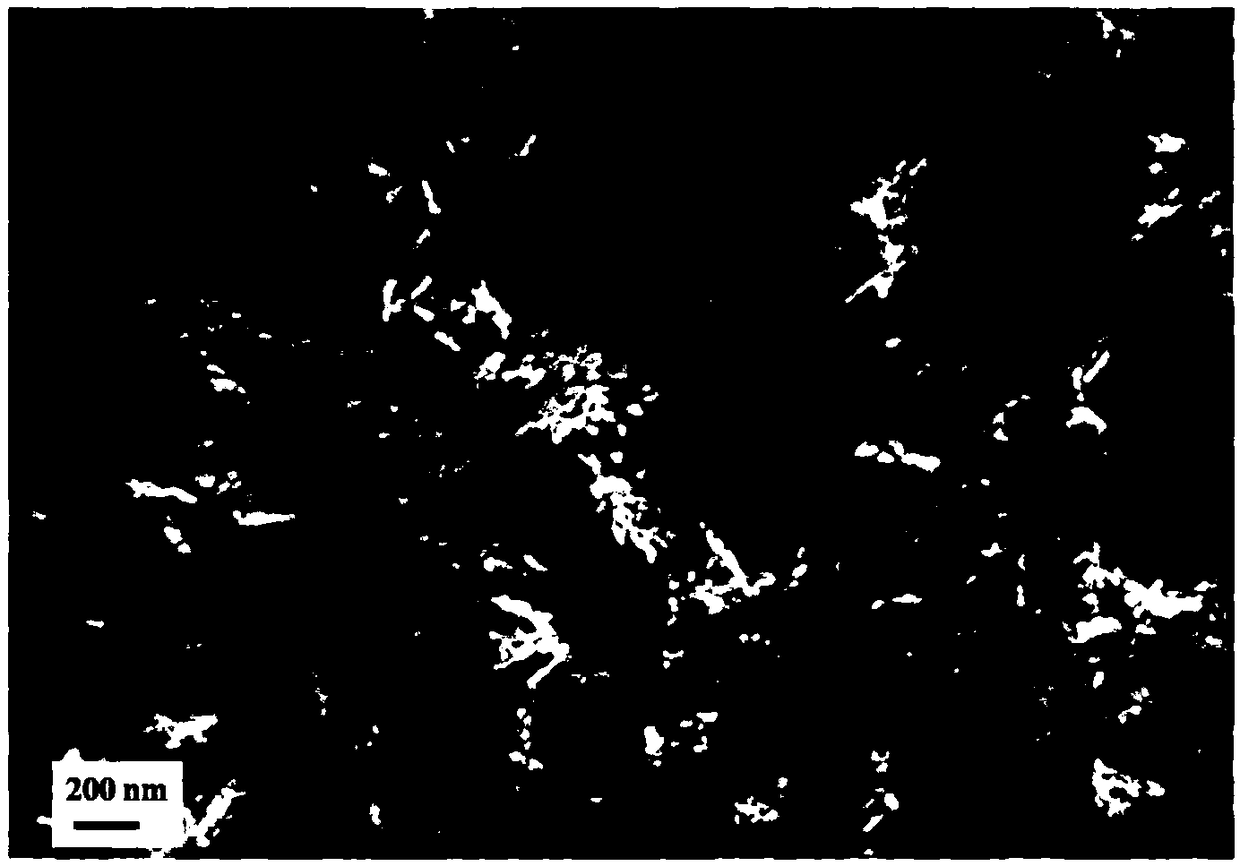

Preparation method and application of a self-assembled nanosheet porous structure cobalt tetroxide-zinc oxide composite material

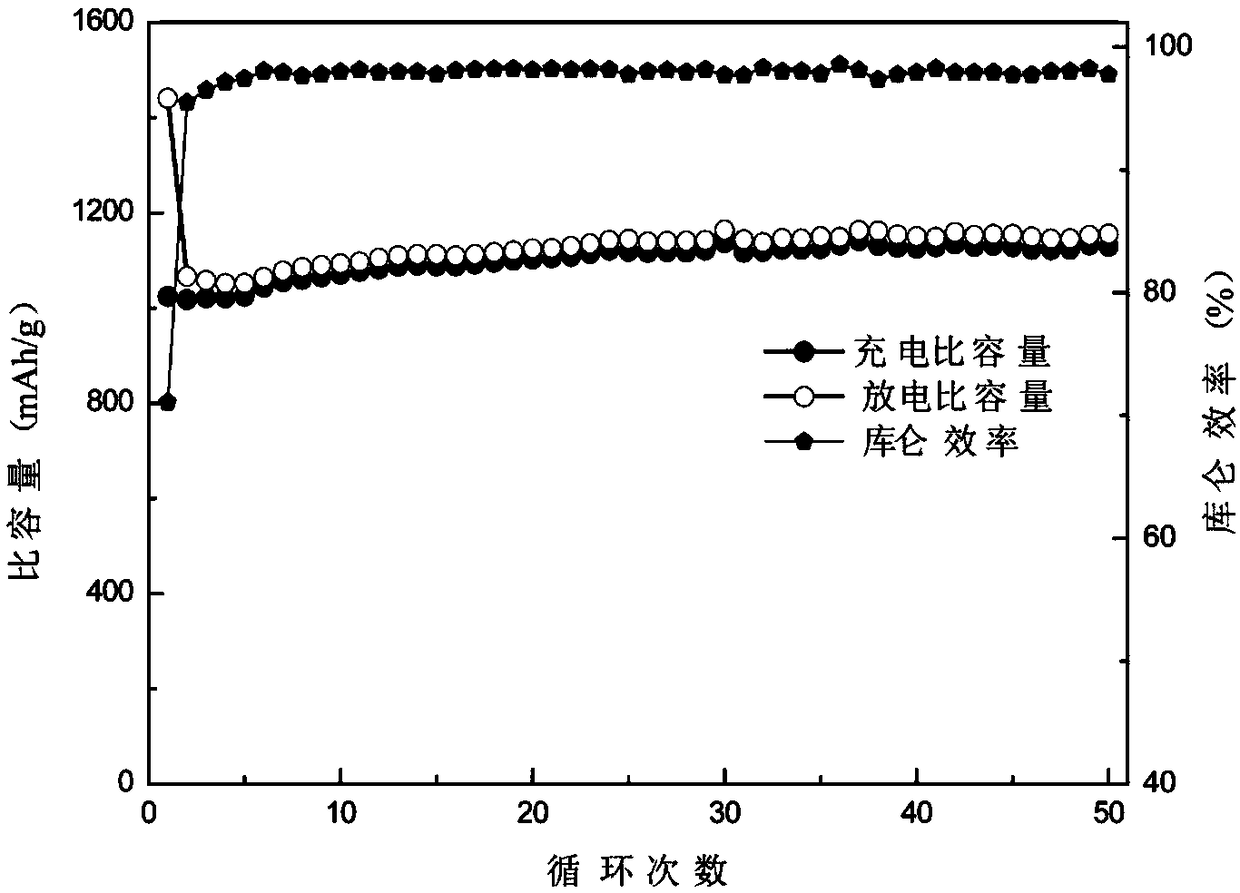

A kind of cobalt tetroxide, nano-sheet technology, applied in nanotechnology, structural parts, nanotechnology and other directions, can solve the problems of specific capacity, cyclability and stability need to be improved, and achieve a favorable volume expansion effect, high specific capacity, convenient The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this example, a self-assembled nanosheet porous structure Co 3 o 4 -The preparation method of ZnO composite material, comprises the following steps:

[0039] S1: Weigh 3mmol of CoCl 2 ·6H 2 O and 3mmol ZnCl 2 Dissolve in a solvent composed of 60mL deionized water and 30mL absolute ethanol, and stir to obtain a uniform mixed salt solution;

[0040] S2: Measure 30 mL of triethanolamine and add it to the mixed salt solution obtained in S1, and continue stirring for 1 hour to make it evenly mixed to obtain a complex solution;

[0041] S3: Pour the complex solution obtained in S2 into a 150mL polytetrafluoroethylene hydrothermal reaction kettle, heat to 180°C and react for 12h to obtain a suspension;

[0042] S4: Filtrate the suspension obtained in S3, collect the precipitate, and perform centrifugation washing with ethanol and deionized water three times each at a speed of 7500r / min, and vacuum dry at 70°C for 12h to obtain a Co-Zn-based precursor thing;

[0043] ...

Embodiment 2

[0046] In this example, a self-assembled nanosheet porous structure Co 3 o 4 -The preparation method of ZnO composite material, comprises the following steps:

[0047] S1: Weigh 3mmol of CoCl 2 ·6H 2 O and 3mmol ZnCl 2 Dissolve in a solvent consisting of 50mL deionized water and 30mL absolute ethanol, and stir to obtain a uniform mixed salt solution;

[0048] S2: Measure 40 mL of triethanolamine and add it to the mixed salt solution obtained in S1, and continue to stir for 1 hour to make it evenly mixed to obtain a complex solution;

[0049] S3: Pour the complex solution obtained in S2 into a 150mL polytetrafluoroethylene hydrothermal reaction kettle, heat to 180°C and react for 12h to obtain a suspension;

[0050] S4: Filtrate the suspension obtained in S3, collect the precipitate, and perform centrifugation washing with ethanol and deionized water three times each at a speed of 7500r / min, and vacuum dry at 70°C for 12h to obtain a Co-Zn-based precursor thing;

[0051]...

Embodiment 3

[0054] In this example, a self-assembled nanosheet porous structure Co 3 o 4 -The preparation method of ZnO composite material, comprises the following steps:

[0055] S1: Weigh 3mmol of CoCl 2 ·6H 2 O and 1 mmol ZnCl 2 Dissolve in a solvent composed of 60mL deionized water and 30mL ethylene glycol, and stir to obtain a uniform mixed salt solution;

[0056] S2: Measure 30 mL of triethanolamine and add it to the mixed salt solution obtained in S1, and continue stirring for 1 hour to make it evenly mixed to obtain a complex solution;

[0057] S3: Pour the complex solution obtained in S2 into a 150mL polytetrafluoroethylene hydrothermal reaction kettle, heat to 160°C and react for 20h to obtain a suspension;

[0058] S4: Filtrate the suspension obtained in S3, collect the precipitate, and perform centrifugation washing with ethanol and deionized water for 5 times each at a speed of 10,000r / min, and freeze-dry at -50°C with a pressure of 1.33Pa and a time of 40h. Obtain Co-Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com