Preparation method of positive electrode of transition metal doped antimonene composite lithium-sulfur battery

A transition metal and composite electrode technology, which is applied in the direction of lithium batteries, battery electrodes, metal processing equipment, etc., can solve problems such as shedding, achieve the effects of preventing dissolution and diffusion, improving volume expansion effect, and stabilizing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

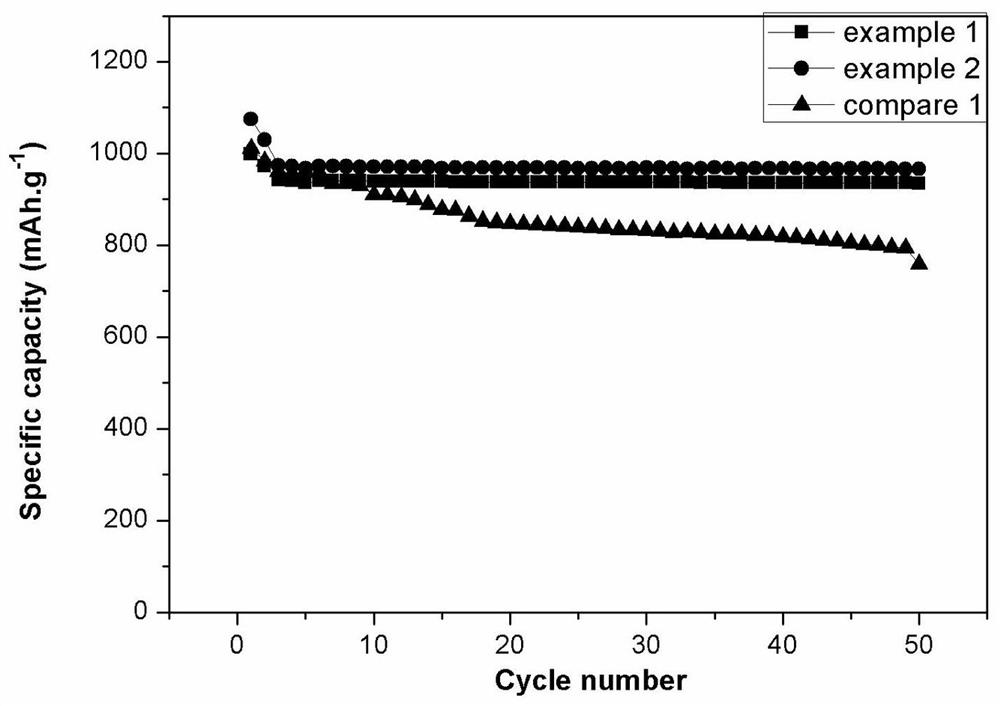

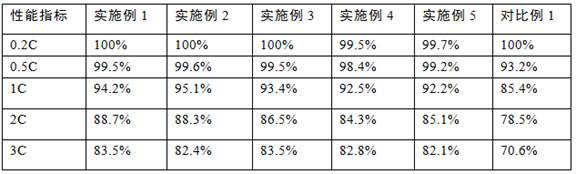

Examples

Embodiment 1

[0036] A method for preparing a positive electrode of a transition metal-doped antimonene composite lithium-sulfur battery, comprising the following steps:

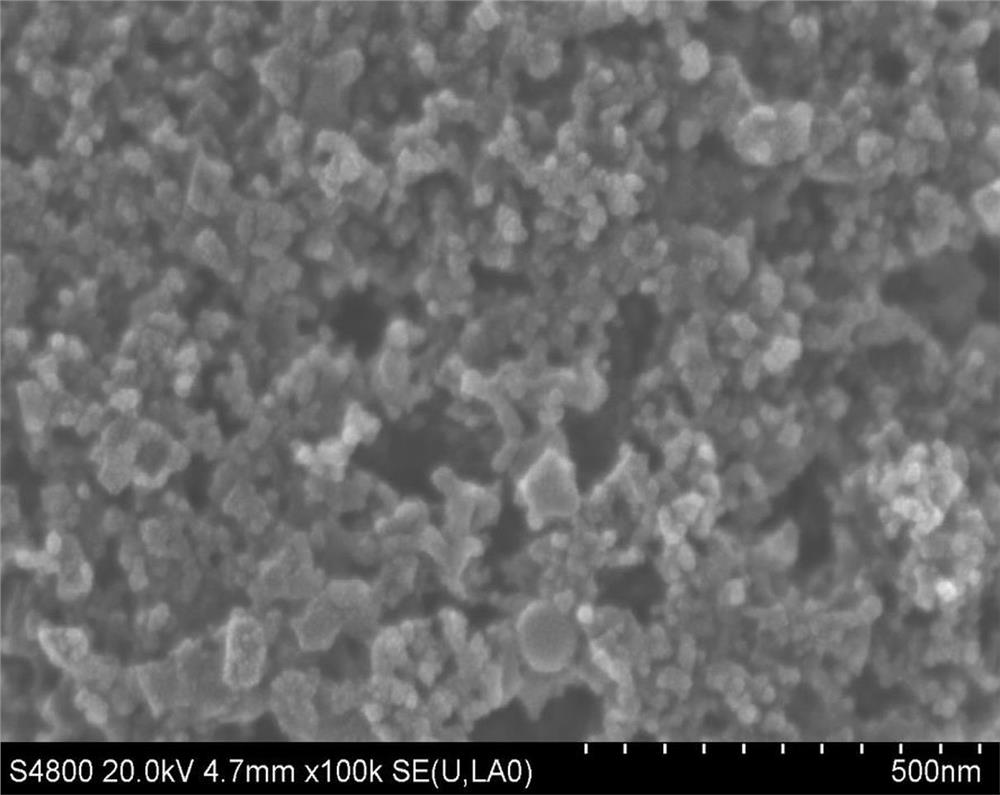

[0037] S1. Synthesis of Antimonene

[0038] Put metal antimony crystals into a mortar, add ethanol and isopropanol mixed solvent (ethanol: isopropanol = 1:2), and grind in the same direction. After grinding for 2-12 hours, grind the After the mixture is poured into a cup, the cup is placed in an ultrasonic instrument for ultrasonication. After ultrasonication for 2-14 hours, the mixture is centrifuged to obtain several layers of antimonene. Wherein, the centrifugal speed of centrifugal separation is 5000-15000 rpm, and the obtained antimonene has 10-100 layers and a thickness of 2-10 nm.

[0039] S2. Preparation of antimonene transition metal composite electrode

[0040] Under alkaline conditions with a pH value of 9-10, mix the antimonene material obtained in step S1 with metal cobalt Co in a nickel boat, and place it ...

Embodiment 2

[0046] A method for preparing a positive electrode of a transition metal-doped antimonene composite lithium-sulfur battery, comprising the following steps:

[0047] S1. Synthesis of Antimonene

[0048] Put metal antimony crystals into a mortar, add ethanol and isopropanol mixed solvent (ethanol: isopropanol = 1:2), and grind in the same direction. After grinding for 2-12 hours, grind the After the mixture is poured into a cup, the cup is placed in an ultrasonic instrument for ultrasonication. After ultrasonication for 2-14 hours, the mixture is centrifuged to obtain several layers of antimonene. Wherein, the centrifugal speed of centrifugal separation is 5000-15000 rpm, and the obtained antimonene has 10-100 layers and a thickness of 2-10 nm.

[0049] S2. Preparation of antimonene transition metal composite electrode

[0050] Under alkaline conditions with a pH value of 9-10, mix the antimonene material obtained in step S1 with metal zinc Zn in a nickel boat, and place it in...

Embodiment 3

[0057] A method for preparing a positive electrode of a transition metal-doped antimonene composite lithium-sulfur battery, comprising the following steps:

[0058] S1. Synthesis of Antimonene

[0059] Put metal antimony crystals into a mortar, add ethanol and isopropanol mixed solvent (ethanol: isopropanol = 1:2), and grind in the same direction. After grinding for 2-12 hours, grind the After the mixture is poured into a cup, the cup is placed in an ultrasonic instrument for ultrasonication. After ultrasonication for 2-14 hours, the mixture is centrifuged to obtain several layers of antimonene. Wherein, the centrifugal speed of centrifugal separation is 5000-15000 rpm, and the obtained antimonene has 10-100 layers and a thickness of 2-10 nm.

[0060] S2. Preparation of antimonene transition metal composite electrode

[0061] Under alkaline conditions with a pH value of 9-10, mix the antimonene material obtained in step S1 with metal chromium Cr in a nickel boat, and place i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com