Method for preparing loaded transitional metal phosphide catalyst

A transition metal and phosphide technology, which is applied in the rapid preparation of supported transition metal phosphide catalysts and high-efficiency fields, can solve problems such as high reduction temperature, long reduction time, and complicated process, and achieve high catalytic performance, improved dispersion, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Catalyst preparation: the supported transition metal phosphide catalyst involved in the present invention adopts an isohumid point wet impregnation method to load the metal active component on the carrier. Here, taking nickel phosphide / activated carbon as an example, the preparation of the catalyst of the present invention is generally described.

[0024] Dissolve 0.559g of nickel chloride hexahydrate in 1ml of distilled water and stir evenly, add the obtained clear solution into 1g of activated carbon for equal volume impregnation, then dry at 120°C for 12 hours, mix and grind the obtained sample with 0.183g of red phosphorus evenly, Get the precursor.

[0025] The obtained precursor was loaded into a vertical catalyst preparation reaction tube, and microwave heating was carried out in a flowing argon or hydrogen atmosphere, and the microwave power was 50W. During the heating process, white smoke (sublimation of white phosphorus) appears in the tube, and the infrared ...

Embodiment 2

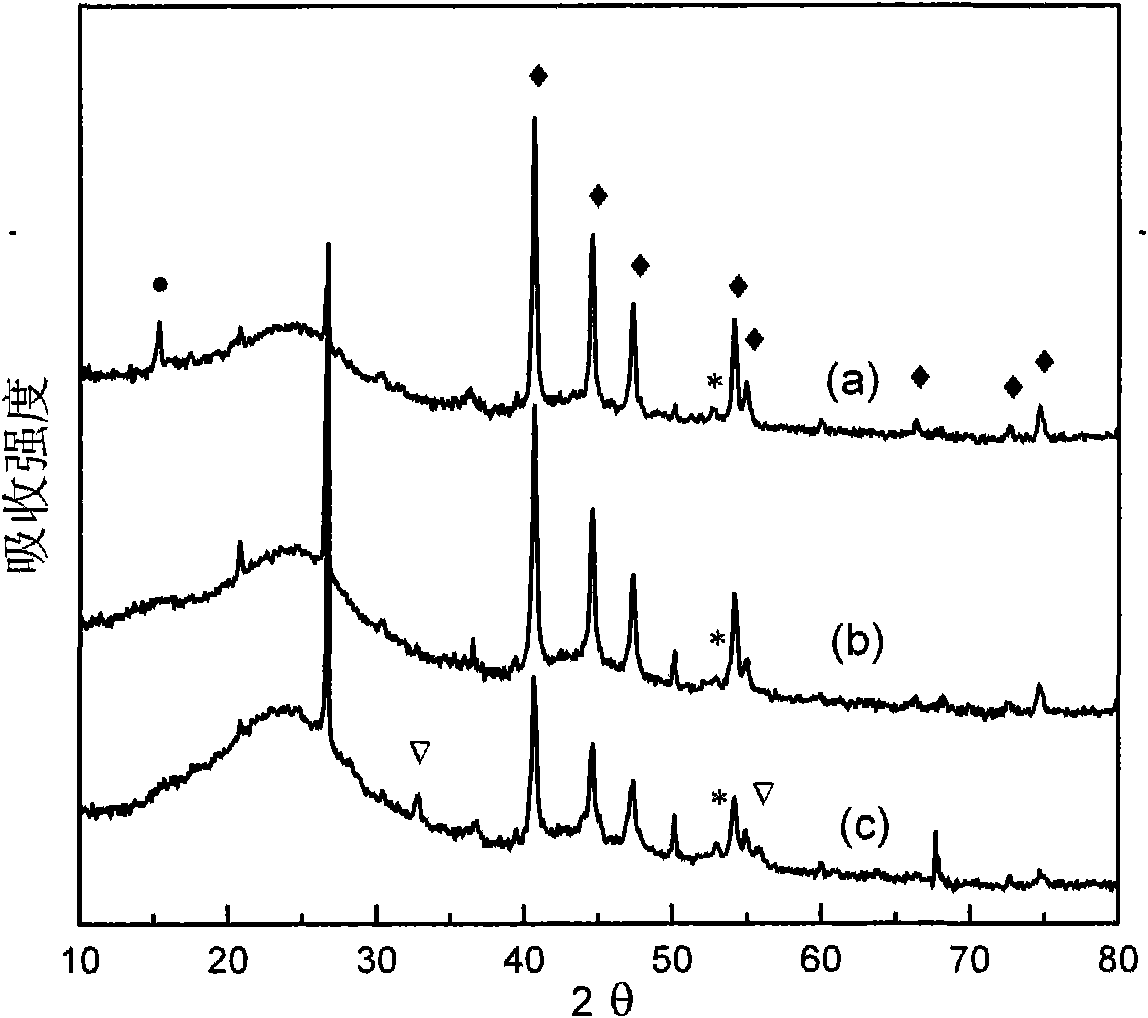

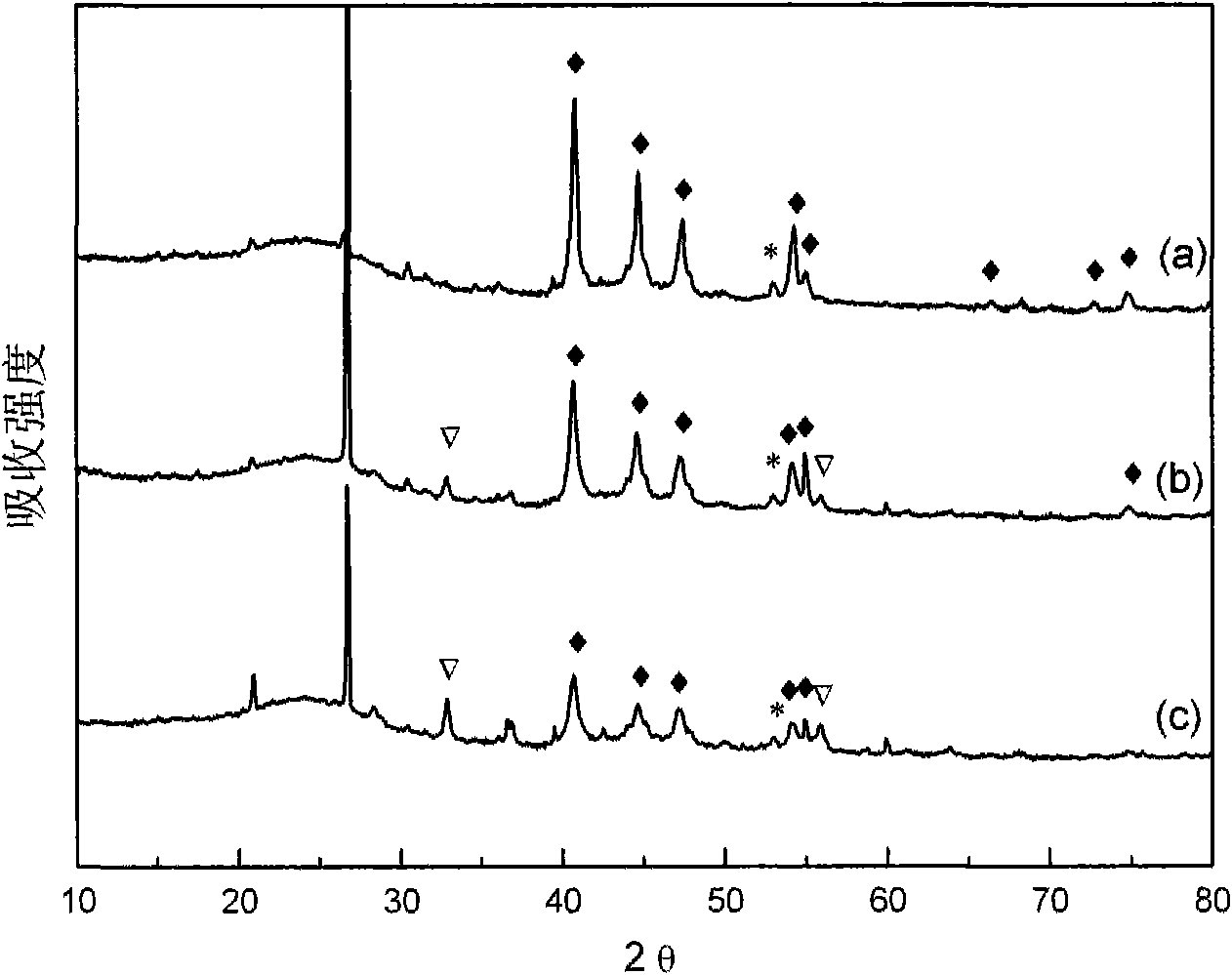

[0027] Preparation result: the preparation process is the same as in Example 1, when the microwave heating process is carried out under an argon atmosphere, the catalyst obtained by different nickel and phosphorus molar ratios (Ni / P=1 / 2, 1 / 3, 1 / 5) , the results of XRD characterization are as follows figure 1 ,from figure 1 It can be seen from the XRD results that after reacting for 5-7 minutes under microwave heating conditions, a phosphide catalyst with a typical crystal phase structure of nickel phosphide can be successfully prepared. The specific results show that when Ni / P=1 / 2, only a small amount of nickel chloride is not phosphated by red phosphorus, and when the phosphorus ratio increases to Ni / P=1 / 3, 1 / 5, the metal is completely Phosphated to generate nickel phosphide.

[0028] The preparation process is the same as in Example 1. When the microwave heating process is carried out under a hydrogen atmosphere, the catalyst obtained by different nickel and phosphorus mol...

Embodiment 3

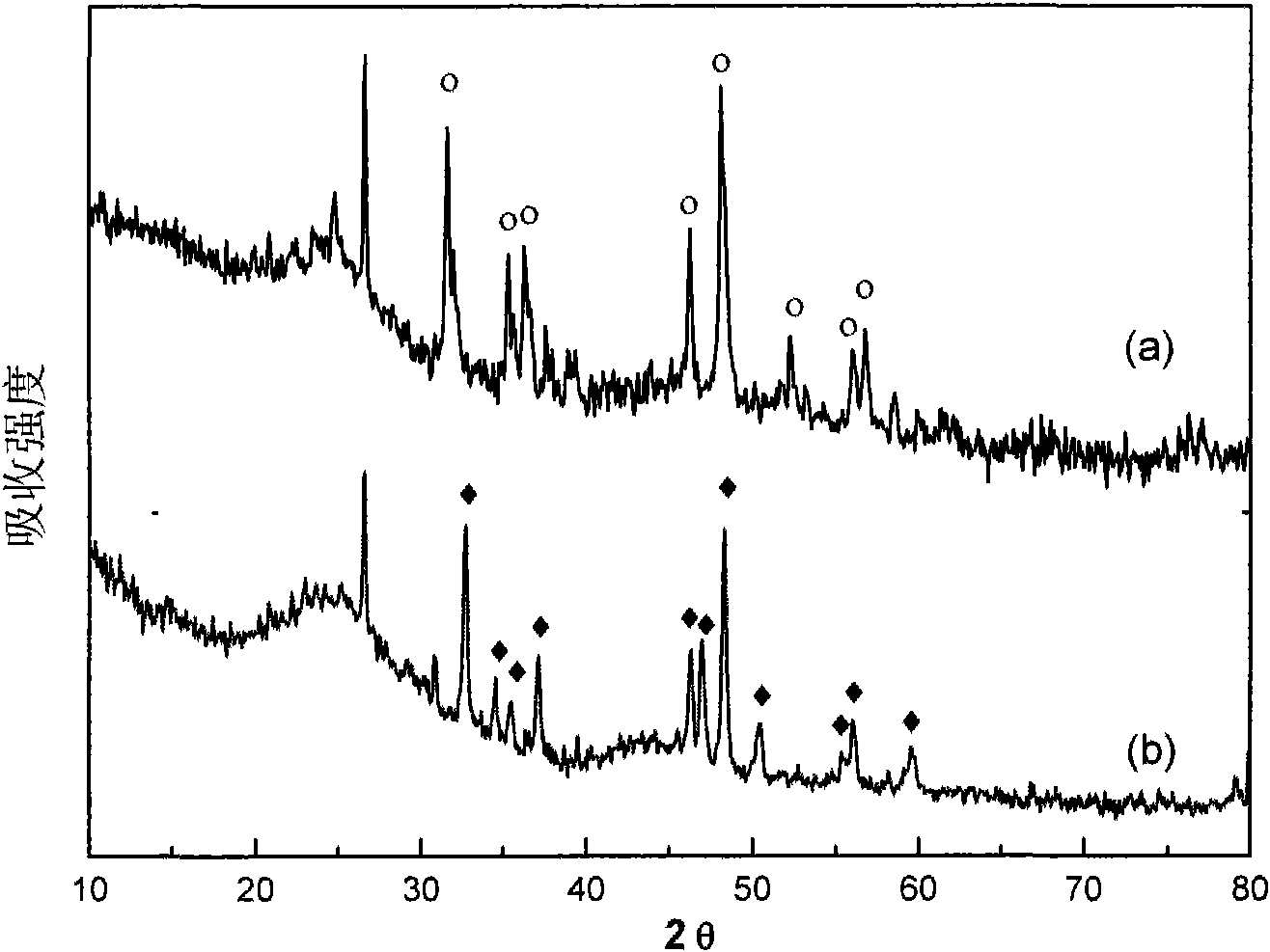

[0030] Utilize the method described in embodiment 1, under hydrogen atmosphere, prepare CoP / AC, the result of XRD characterization of FeP / AC catalyst is as follows image 3 : As can be seen from the results, both cobalt chloride and ferric chloride are completely converted into product phosphides. It shows that this method is also applicable to the preparation of supported metal phosphides of different metals (Group VIB and / or Group VIII).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com