Method for preparing silicon nanotube

A technology of silicon nanotubes and nanospheres, which is applied in the field of preparation of silicon nanotubes, can solve the problems of limited application of silicon nanotubes, difficult to prepare in large quantities, and complicated preparation methods of tubular silicon nanowires, and achieves the effect of large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

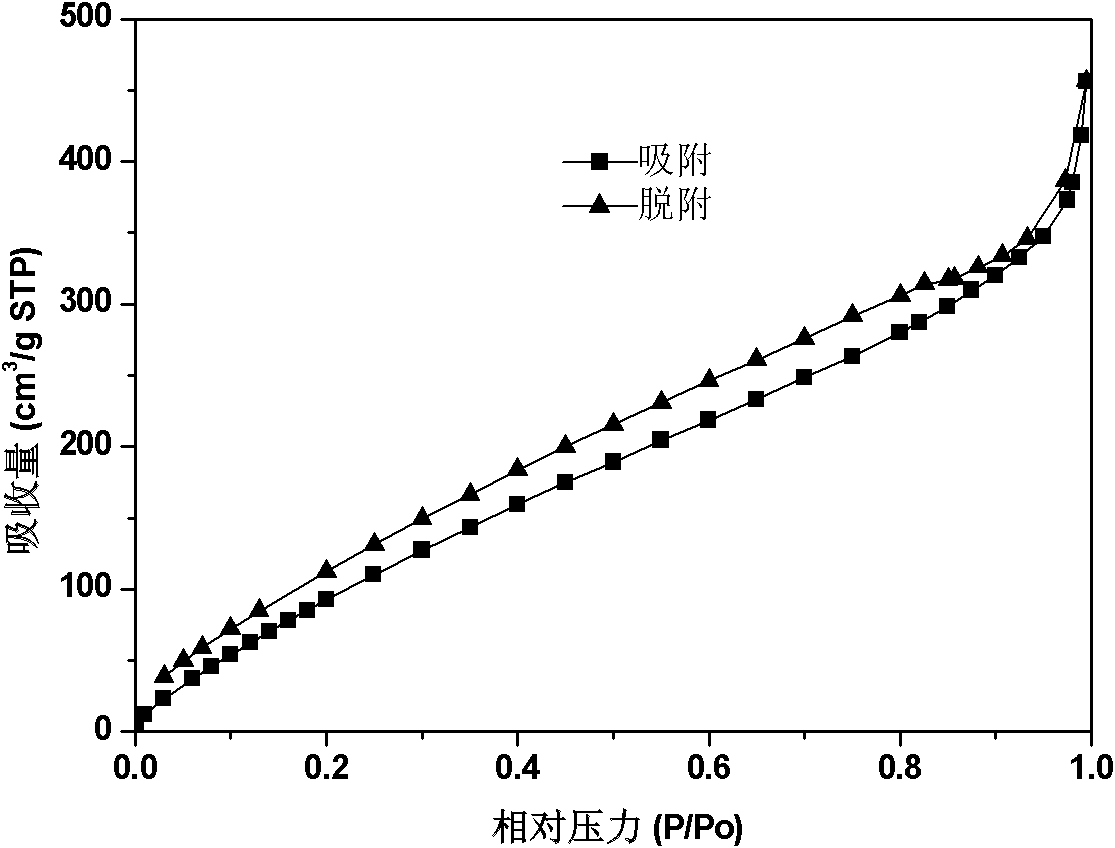

[0016] The method for preparing silicon nanotubes of the present invention uses Mg to SiO 2 The reduction effect of Fe, Ni, Cu, Zn, Nb, Al, Sn, C, etc. as a catalyst, the SiO 2 The nanospheres are reduced to silicon hollow nanotubes, thus obtaining silicon nanomaterials with a large specific surface area. The prepared silicon nanotubes are in the form of gray-black powder, and the inner diameters of the tubes are about 120-170nm. The silicon nanotubes are synthesized in two steps: (1) Hydrothermal synthesis of SiO using surfactants 2 Nanosphere precursor; (2) The solid-phase magnesium thermal method is used to synthesize silicon nanotubes under the action of Fe, Ni, Cu, Zn, Nb, Al, Sn, C and other catalysts.

[0017] The specific operations of the above steps are:

[0018] 1) Add 1 mmol of surfactant cetyltrimethylammonium bromide to the mixed solvent of 1,4-dioxane, ethanol and water, and the molar ratio of the solvent is composed of 1,4-dioxane: Ethanol: water = 2:8:10, stir unt...

Embodiment 1

[0021] The first step: mix 2mL 1,4-dioxane and 8mL ethanol, add 10mL H 2 O, add 1.0mmol cetyltrimethylammonium bromide to the above solution, stir to obtain a clear solution, weigh 8.0mmol urea, add to the above solution, and then stir to obtain a clear solution, slowly drop 2.0mmol orthosilicic acid Ethyl ester, stirred for 1h to obtain a colloidal solution, transferred to a hydrothermal reactor, reacted at 180℃ for 3h, cooled to room temperature, filtered and washed, dried at 60℃ to obtain white SiO 2 powder.

[0022] Step 2: Add 0.060g of the above SiO 2 The powder and 0.024g magnesium powder are mixed uniformly, put into a Nb tube, pass Ar protection, react in a tube furnace at 675°C for 10 hours, cool to room temperature, and still use Ar protection during cooling. The obtained product is protected by 2mol / Wash with L HCl and 0.3% HF, filter, and dry to obtain gray-black powder.

Embodiment 2

[0024] The first step: mix 2mL 1,4-dioxane and 8mL ethanol, add 10mL H 2 O, add 1.0mmol cetyltrimethylammonium bromide to the above solution, stir to obtain a clear solution, weigh 8.0mmol urea, add to the above solution, and then stir to obtain a clear solution, slowly drop 2.0mmol orthosilicic acid Ethyl ester, stirred for 1h to obtain a colloidal solution, transferred to a hydrothermal reactor, reacted at 180℃ for 3h, cooled to room temperature, filtered and washed, dried at 60℃ to obtain white SiO 2 powder.

[0025] Step 2: Add 0.060g of the above SiO 2 Mix the powder with 0.024g magnesium powder and 0.001g Nb powder evenly, put them in a quartz tube, pass in Ar protection, react in a tube furnace at 675°C for 10 hours, cool to room temperature, and still use Ar protection during cooling to obtain The product was washed with 2mol / L HCl and dilute HF, filtered, and dried to obtain gray-black powder.

[0026] figure 1 The scanning electron microscope test showed that the obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com