Transparent super-hydrophobic coating and preparation method thereof

A super-hydrophobic coating, transparent technology, applied in coatings and other directions, can solve problems such as fluorine pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

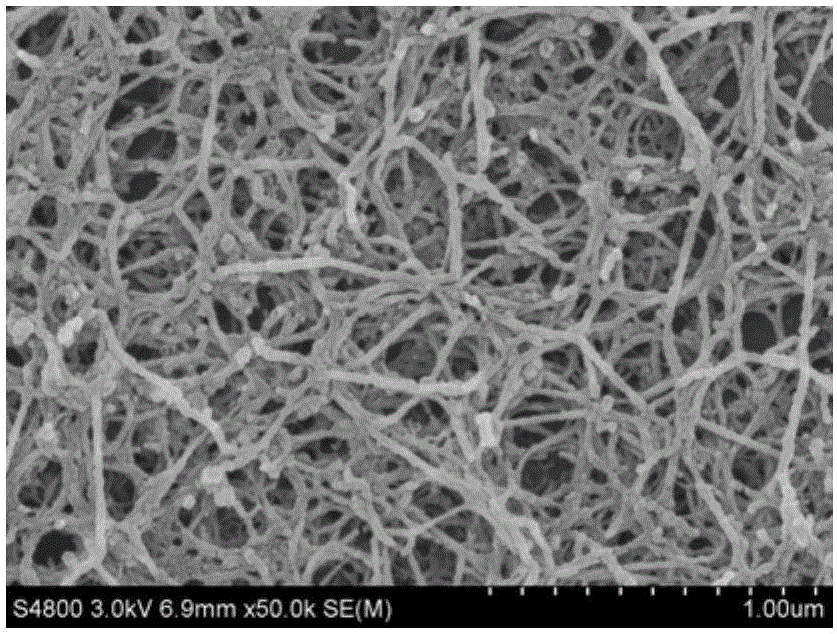

[0027] a. Preparation of octadecylamine-modified carbon nanotubes

[0028] The carbon nanotubes are sequentially modified with concentrated nitric acid (65% mass fraction), thionyl chloride, and octadecylamine to obtain octadecylamine-modified carbon nanotubes.

[0029] b. Preparation of coating solution

[0030] A certain amount of polydimethylsiloxane (PDMS: the product obtained by mixing Dow Corning 184 prepolymer and curing agent at a mass ratio of 10:1) was dissolved in tetrahydrofuran. Then take an appropriate amount of octadecylamine-modified carbon nanotubes and place them in a tetrahydrofuran solution, and sonicate for 15 minutes to obtain a uniformly dispersed coating solution. Wherein, the amount of PDMS and the amount of octadecylamine-modified carbon nanotubes are subject to the solubility.

[0031] c. Preparation of transparent superhydrophobic coating

[0032] Wash the glass substrate with acetone, distilled water, and ethanol in sequence, and dry it for late...

Embodiment 1

[0040] a. Preparation of octadecylamine-modified carbon nanotubes

[0041] The carbon nanotubes are sequentially modified with concentrated nitric acid (65% mass fraction), thionyl chloride, and octadecylamine to obtain octadecylamine-modified carbon nanotubes.

[0042] b. Preparation of coating solution

[0043] Dissolve PDMS in tetrahydrofuran, keep the concentration of PDMS in tetrahydrofuran at 0.1g / L, then take an appropriate amount of octadecylamine-modified carbon nanotubes in the solution, and keep the concentration of octadecylamine-modified carbon nanotubes in tetrahydrofuran 0.75g / L, ultrasonic 15min to obtain a uniformly dispersed coating liquid.

[0044] c. Preparation of transparent superhydrophobic coating

[0045] Wash the glass substrate with acetone, distilled water, and ethanol in sequence, and dry it for later use. Spray the obtained coating solution vertically on the glass surface, keep the spraying pressure at 0.4kPa, spraying at a distance of 10cm, an...

Embodiment 2

[0047] a. Preparation of octadecylamine-modified carbon nanotubes

[0048] The carbon nanotubes are sequentially modified with concentrated nitric acid (65% mass fraction), thionyl chloride, and octadecylamine to obtain octadecylamine-modified carbon nanotubes.

[0049] b. Preparation of coating solution

[0050] Dissolve PDMS in tetrahydrofuran, keep the concentration of PDMS in tetrahydrofuran at 0.2g / L, then take an appropriate amount of octadecylamine-modified carbon nanotubes in the solution, and keep the concentration of octadecylamine-modified carbon nanotubes in tetrahydrofuran 0.85g / L, ultrasonic 15min to obtain a uniformly dispersed coating liquid.

[0051] c. Preparation of transparent superhydrophobic coating

[0052] Wash the glass substrate with acetone, distilled water, and ethanol in sequence, and dry it for later use. Spray the obtained coating solution vertically on the glass surface, keep the spraying pressure at 0.5kPa, spraying at a distance of 15cm, an...

PUM

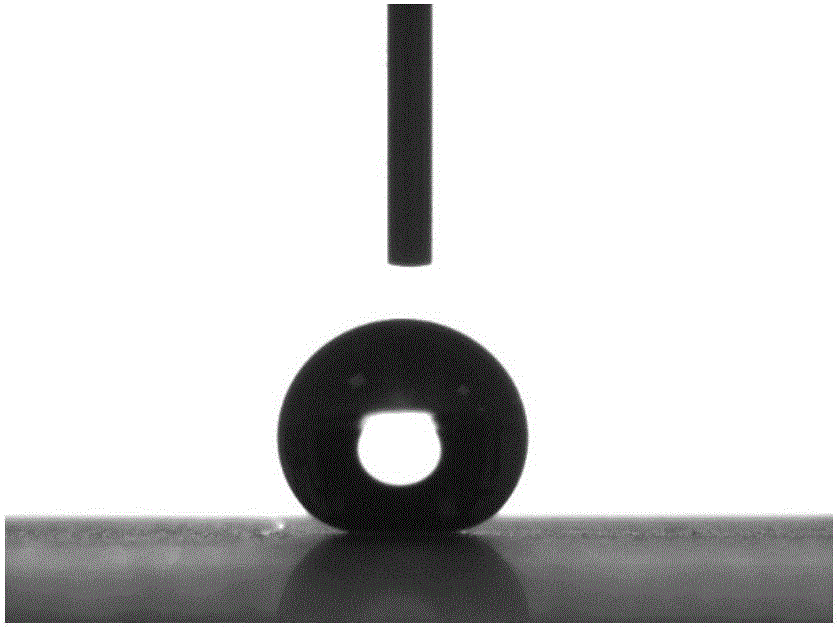

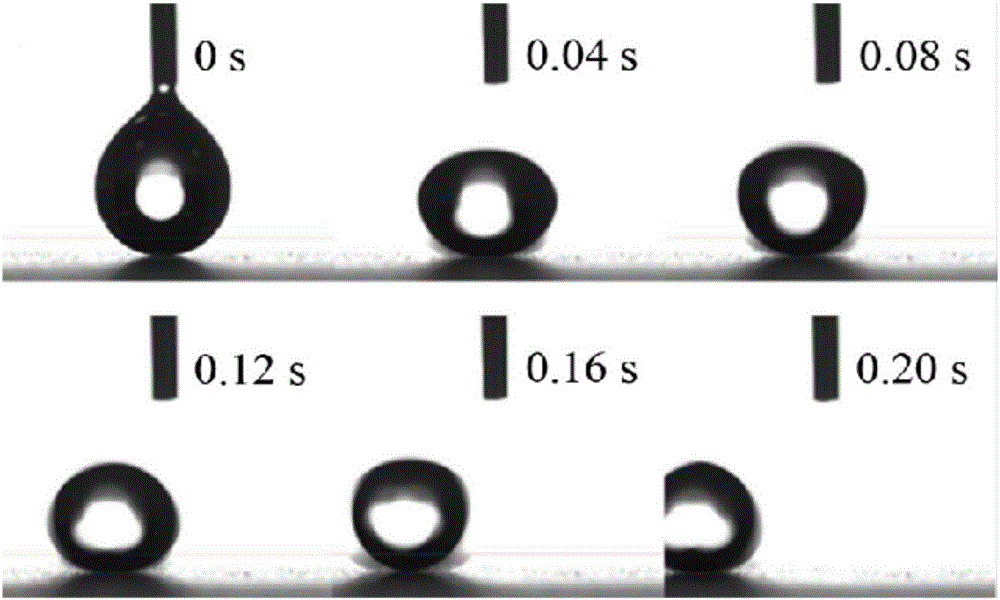

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com