Preparation method for nano-tube

A technology of silicon nanotubes and silicon monoxide, which is applied in the field of semiconductor microelectronics and nanoelectronics, can solve problems such as damage, silicon nanotube corrosion, and low yield, and achieve the effects of simple process, cheap equipment, and complete crystal structure

Inactive Publication Date: 2008-10-15

FUDAN UNIV

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the method of preparing silicon nanotubes mainly adopts the template method or hydrothermal method. The structure of silicon nanotubes prepared by the template method is severely corroded and destroyed when the template is removed, while the hydrothermal method requires ultra-high pressure hydrothermal conditions, and the preparation The yield of silicon nanotubes is very low, which restricts the application of silicon nanotubes. Therefore, the preparation of silicon nanotubes with conventional equipment and simple processes is still one of the problems in today's scientific and technological circles and industries.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

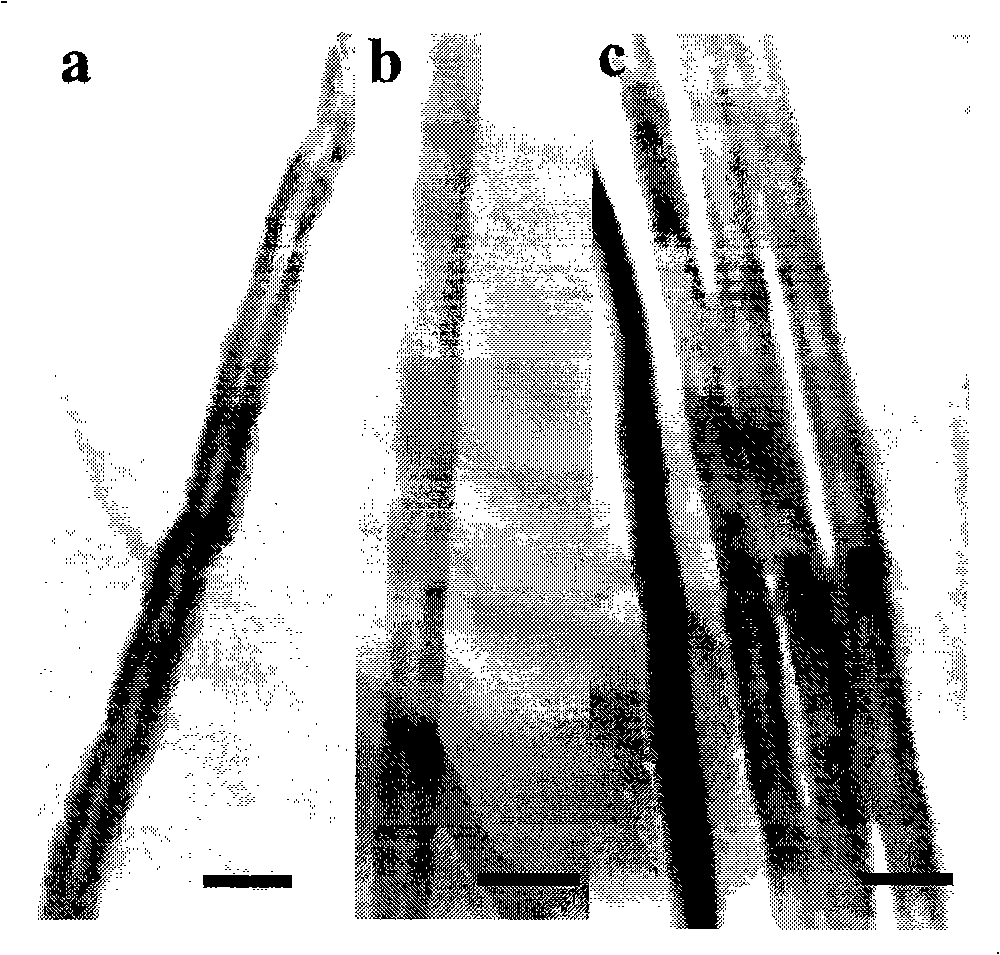

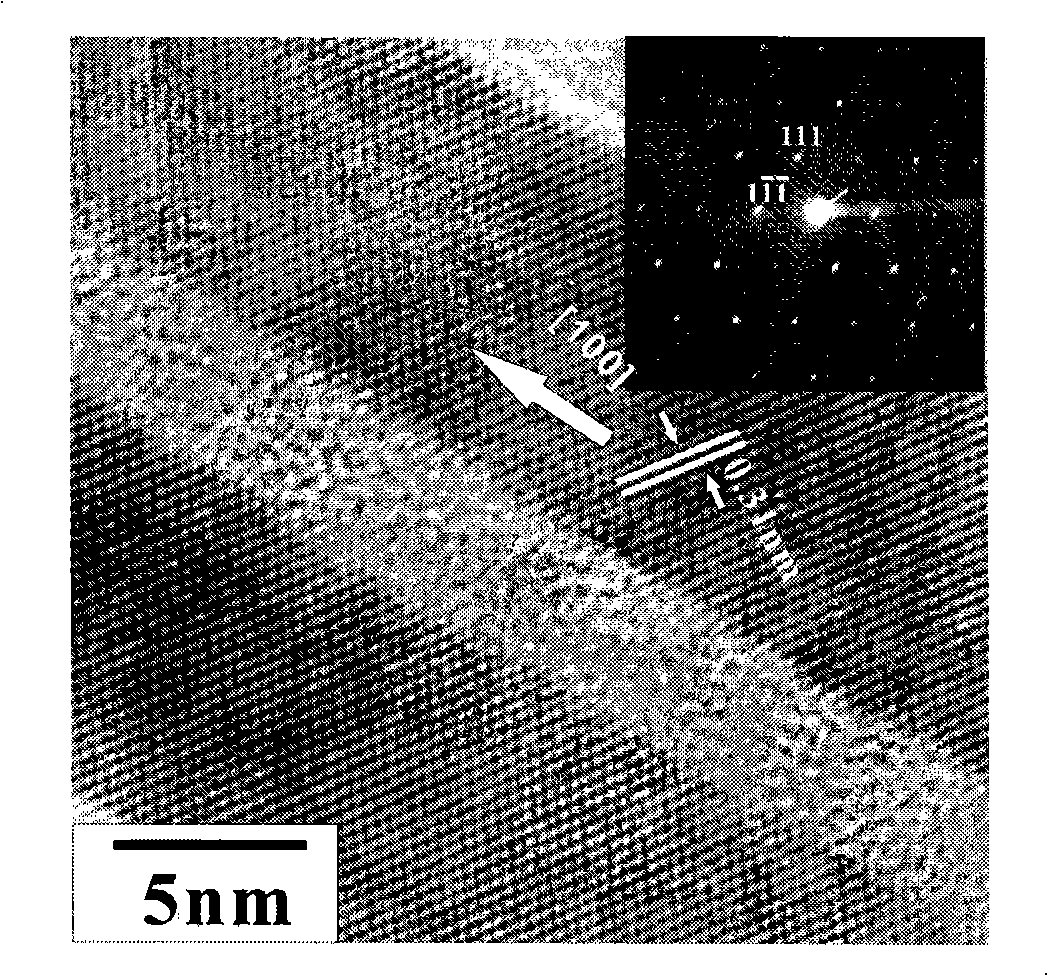

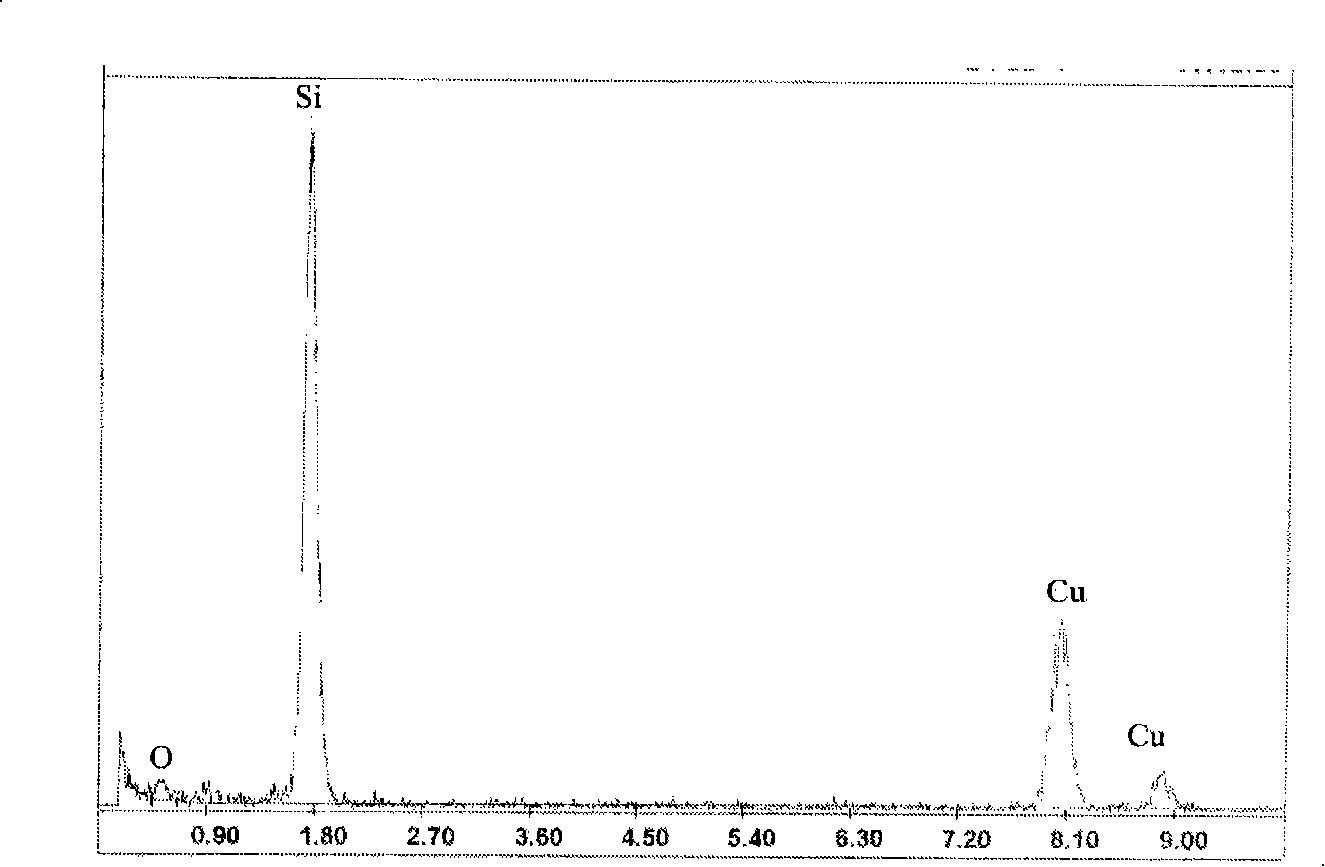

Login to View More Abstract

The invention is a method for preparing a silicon nanotube, which takes the mixed powder of SiO, Si, etc. as the starting material and a small amount of rare earth elements as an indirect catalyst, evaporates the material under the conditions of high temperature and low air pressure, and causes the silicon atoms to accumulate and nucleate at a proper deposition temperature, thereby preparing the hollow-structured silicon nanotube. The method for preparing the silicon nanotube has the advantages of simple process, low-cost equipment, complete crystal structure of the nanotube, and capability for meeting the industrial requirements. The successful preparation of the nanotube provides a practicality foundation for the nanuotube to be widely applied in nanoelectronic devices in the future, and the theoretical research of the nanotube is verified from the experiment.

Description

A kind of preparation method of silicon nanotube technical field The invention belongs to the technical field of semiconductor microelectronics and nanoelectronics, and in particular relates to a method for preparing silicon nanotubes. Background technique Since the end of the last century, one-dimensional nanomaterials have been a research hotspot in many interdisciplinary fields such as physics, chemistry, materials science, and microelectronics. The one-dimensional nanostructure of silicon has the stable semiconductor properties of bulk silicon materials, and Compatible with contemporary mature silicon technology, it is expected to be widely used in nano-devices in the future and make "Moore's Law" guide the development of the semiconductor industry within the maximum time. Si and C are in the same main cluster in the periodic table of elements. Due to the difference in the hybridization of valence electrons between Si and C, C exists in the form of nanotubes, while Si ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B33/021

Inventor 陈扬文江素华邵丙铣王炜

Owner FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com