Method for manufacturing amorphous carbon and multi-walled carbon nano-tube composite electrode materials on basis of polypyrrole carbonization

A technology of multi-walled carbon nanotubes and amorphous carbon, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of metal lithium deposition, safety hazards, and low lithium intercalation potential, and achieve low self-discharge rate and low cost , no memory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing an amorphous carbon and multi-walled carbon nanotube composite electrode material based on polypyrrole carbonization, the specific preparation steps are as follows:

[0033] a. Mix 0.05mmol methyl orange and 20ml deionized water and then carry out magnetic stirring treatment to obtain a methyl orange aqueous solution; add 0.5mmol ferric chloride and 0.5mmol pyrrole to the methyl orange aqueous solution in turn and stir at room temperature for 12 hours Obtaining polypyrrole; washing the polypyrrole with alcohol and deionized water to make it neutral, and then vacuum drying at 50°C for 10 hours;

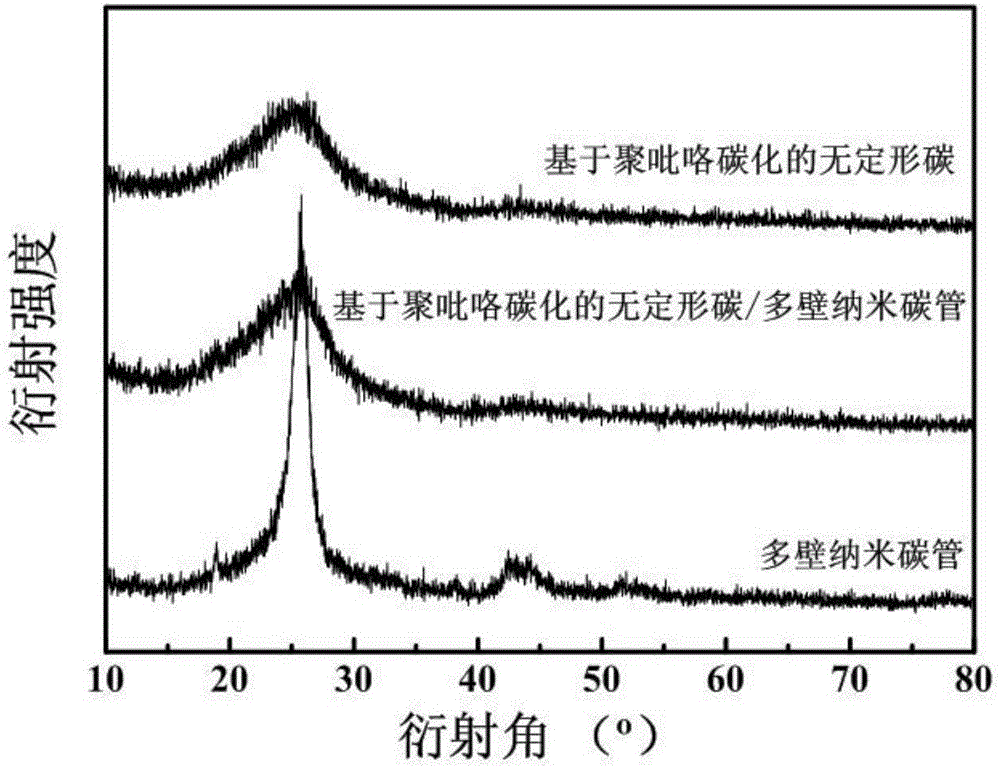

[0034] b. Carbonizing polypyrrole in a tube furnace at 700°C for 1 hour to obtain amorphous carbon;

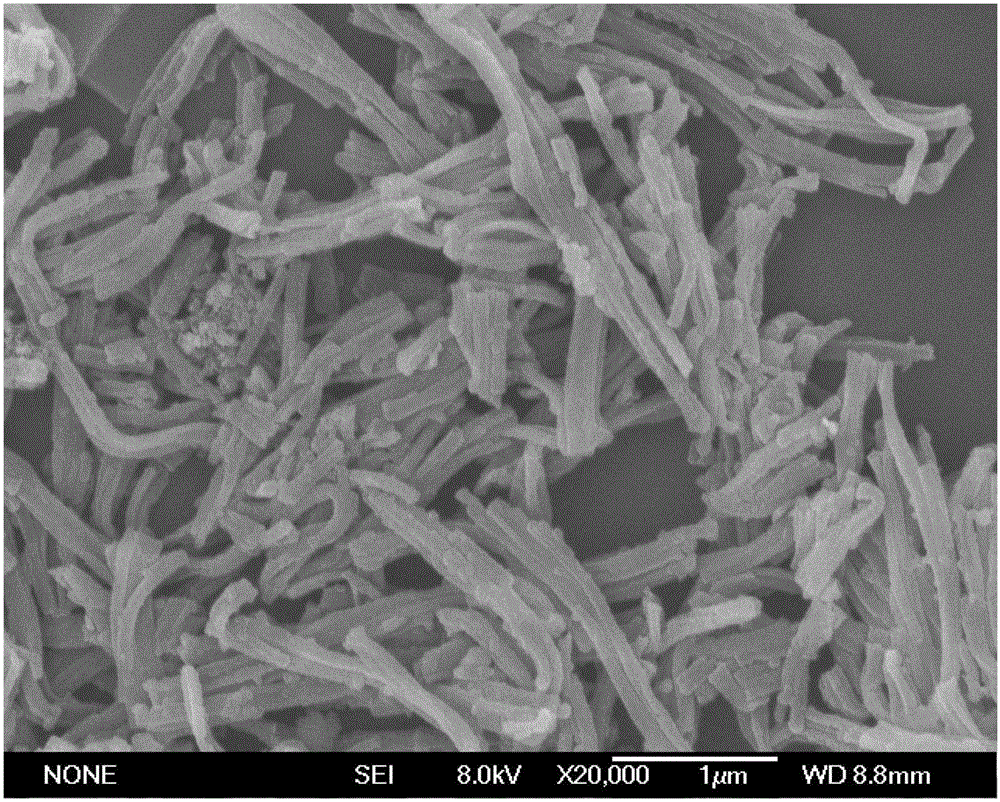

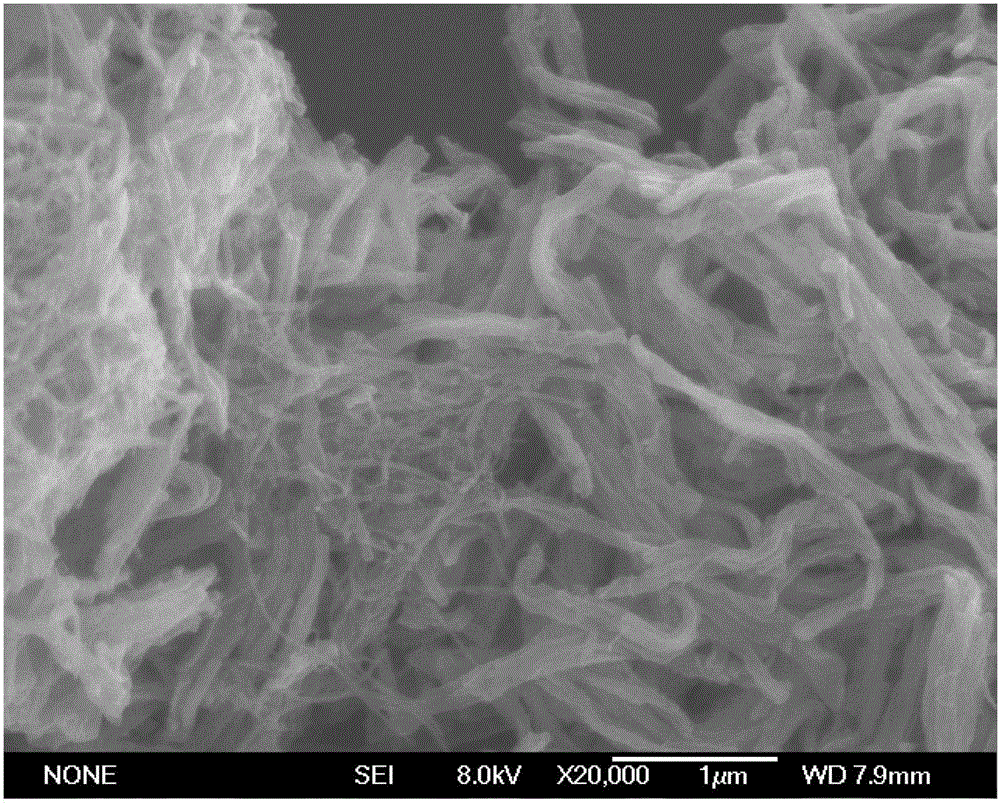

[0035] c. Amorphous carbon and multi-walled carbon nanotubes were magnetically stirred in ethanol for 4 hours in a mass ratio of 90:10, and vacuum-dried at 50°C for 10 hours to obtain amorphous carbon and multi-walled carbon nanotubes based on polypyrrole ...

Embodiment 2

[0037] A method for preparing an amorphous carbon and multi-walled carbon nanotube composite electrode material based on polypyrrole carbonization, the specific preparation steps are as follows:

[0038] a. After mixing 0.15mmol methyl orange and 30ml deionized water, carry out magnetic stirring treatment to obtain methyl orange aqueous solution; add 1.5mmol ferric chloride and 1.5mmol pyrrole in the methyl orange aqueous solution successively and stir at room temperature for 24 Obtain polypyrrole in 1 hour; Wash polypyrrole with alcohol and deionized water respectively to make it neutral, then vacuum dry at 60°C for 24 hours;

[0039] b. Carbonizing polypyrrole in a tube furnace at 750°C for 3 hours to obtain amorphous carbon;

[0040] c. Amorphous carbon and multi-walled carbon nanotubes were magnetically stirred in ethanol at a mass ratio of 98:2 for 6 hours, and vacuum-dried at 60°C for 24 hours to obtain amorphous carbon and multi-walled carbon nanotubes based on polypyrr...

Embodiment 3

[0042]A method for preparing an amorphous carbon and multi-walled carbon nanotube composite electrode material based on polypyrrole carbonization, the specific preparation steps are as follows:

[0043] a. After mixing 0.15mmol methyl orange and 30ml deionized water, carry out magnetic stirring treatment to obtain methyl orange aqueous solution; add 1.5mmol ferric chloride and 1.5mmol pyrrole in the methyl orange aqueous solution successively and stir at room temperature for 24 Obtain polypyrrole in 1 hour; Wash polypyrrole with alcohol and deionized water respectively to make it neutral, then vacuum dry at 60°C for 24 hours;

[0044] b. Carbonizing polypyrrole in a tube furnace at 900°C for 3 hours to obtain amorphous carbon;

[0045] c. Amorphous carbon and multi-walled carbon nanotubes were magnetically stirred in ethanol for 6 hours at a mass ratio of 95:5, and vacuum-dried at 60°C for 24 hours to obtain amorphous carbon and multi-walled carbon nanotubes based on polypyrro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com