One-dimensional ring shaped Nano silicon material and preparation

A bamboo-like, silicon nanotechnology, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as poor controllability and large diameter of nanowires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

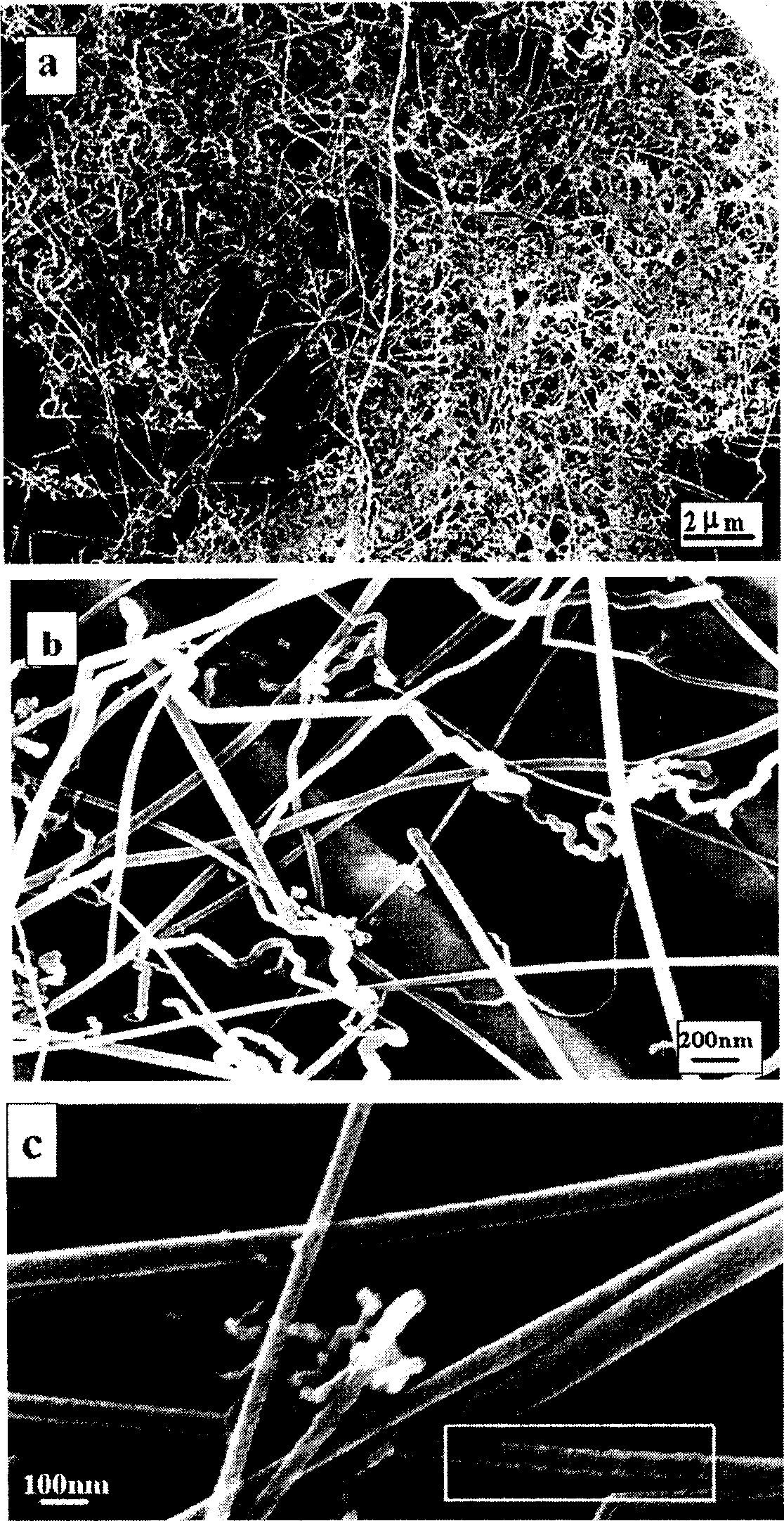

[0022]Example 1 A two-step anodic oxidation method was used to prepare an alumina template with a porous array structure. The pre-cut aluminum foil (thickness 0.2 mm, purity 99.99%) was ultrasonically cleaned in a mixed solution of ethanol, chloroform and acetone (volume ratio 1:2:1), and then in NaOH solution (concentration: 0.5M) for 10 minutes, with distilled water to clean the surface. After the above pretreatment steps are completed, the aluminum foil is electrochemically polished. Polishing is carried out under 10V DC voltage and 70°C water bath. The polishing solution is a mixture of phosphoric acid and glycerin (volume ratio: 1:1). Uniform polishing can be obtained on both sides. The polishing time is generally 10 to 15 minutes. The polished aluminum foil is placed in 0.3M oxalic acid solution at 15°C for anodic oxidation: the aluminum foil is also placed in parallel in the middle of the platinum sheet, the oxidation voltage is 40V, and the oxidation time is about 2...

Embodiment 2

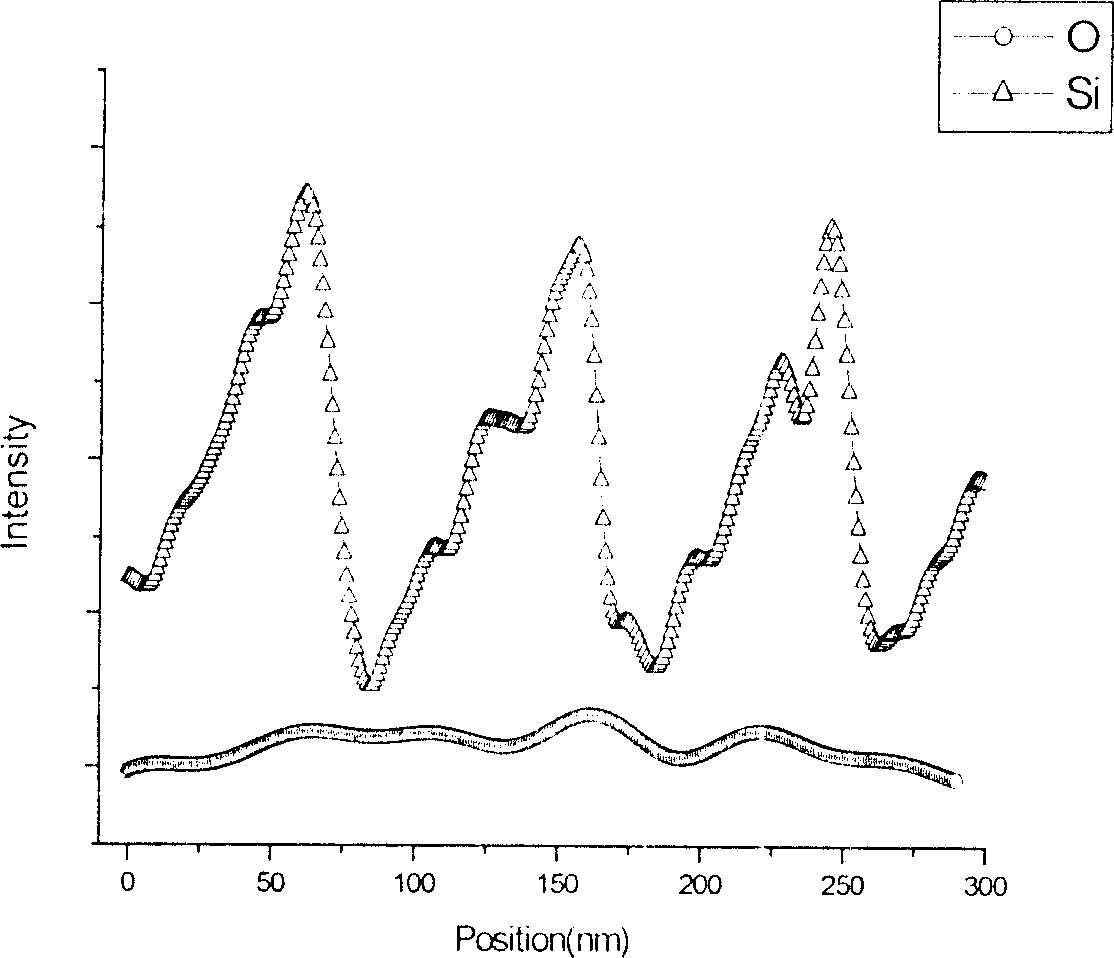

[0026] Embodiment 2 Under the condition that the conditions (temperature, pressure) in embodiment 1 are all constant, when starting to react at 470 DEG C, the flow of SiH is set to 5 sccm, as Figure 5 As shown, the product form changes at this time, which is different from the previous form (such as Figure 4 As shown, the flow rate of SiH4 is 10 sccm) compared with the internal cavities arranged more tightly, the interlayers between the cavities have structural defects, and even communicate with each other, showing a completely hollow tubular shape.

Embodiment 3

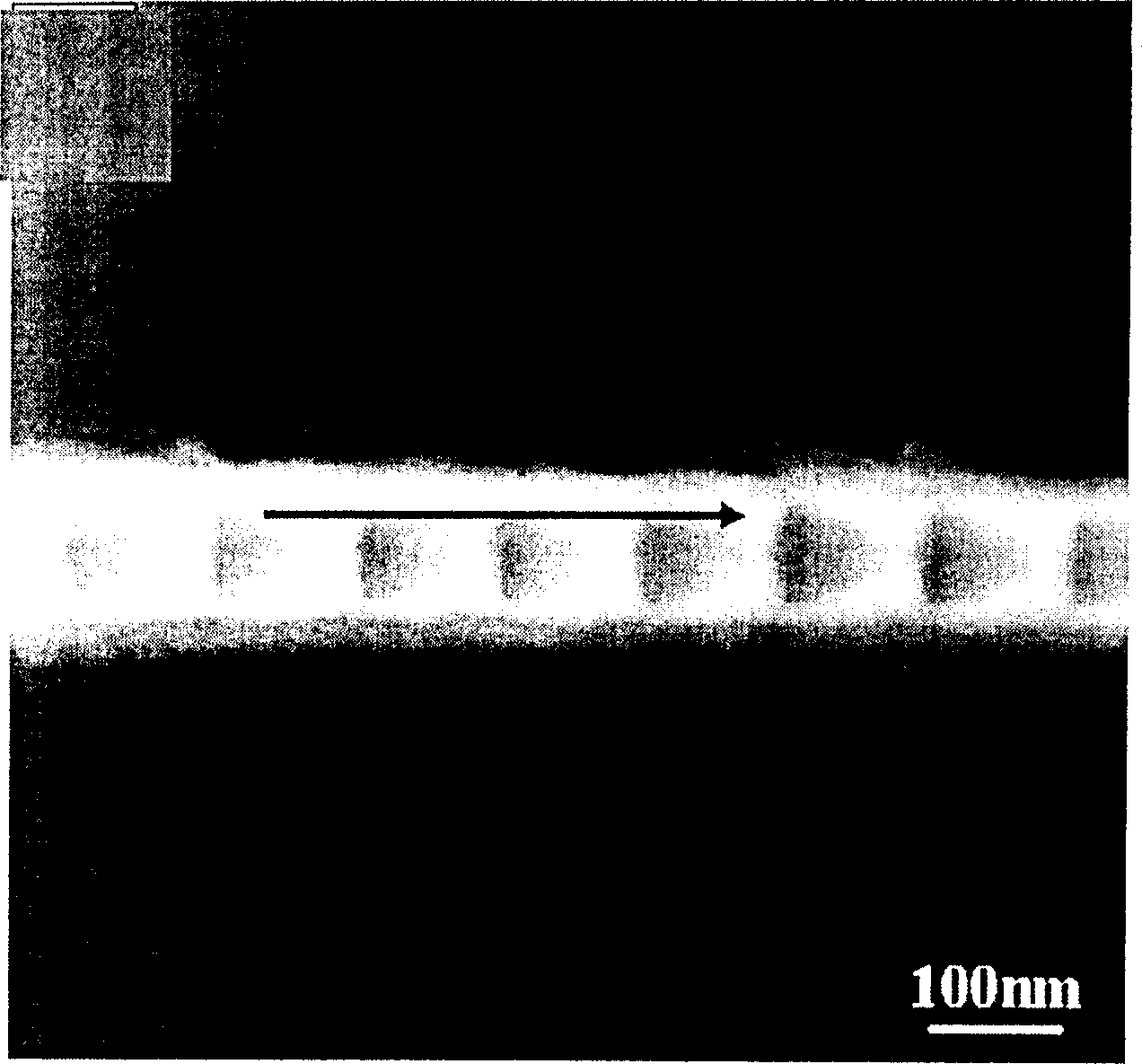

[0027] Embodiment 3 If in the process that reaction takes place, the SiH among the embodiment 2 The flow is adjusted to 10sccm rapidly by 30sccm, as Figure 6 As shown, the one-dimensional structure changes from a solid linear shape to a bamboo joint shape, and its solid part presents a better crystalline structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com