Method for preparing self-cleaning fluorocarbon paint

A fluorocarbon paint, self-cleaning technology, applied in biocide-containing paints, anti-fouling/underwater coatings, etc., can solve the problem that the surface of fluorocarbon paint is easy to be stained, and achieve good chemical stability and low surface free energy , good dispersion, low surface energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

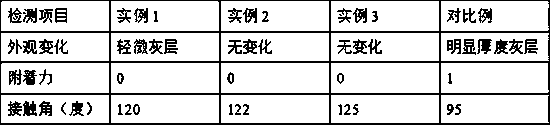

Examples

example 1

[0023]Mix 200mL of absolute ethanol with 100mL of 2% perfluorooctyltriethoxysilane aqueous solution to obtain a siloxane solution, adjust the pH of the siloxane solution to 3.0 with 60% acetic acid by mass fraction, and dissolve the silicon Pour the oxane solution into a beaker, stir and mix with a magnetic stirrer at a speed of 300r / min for 22 hours to obtain a hydrolyzed fluorosilane solution; prepare a titanium dioxide ethanol mixture with a mass concentration of 4 mg / mL, mix the titanium dioxide ethanol mixture with the hydrolyzed The fluorosilane solution was mixed at a volume ratio of 4:1, placed in a beaker, stirred and mixed with a magnetic stirrer at a speed of 400r / min for 7h, then placed in a high-speed centrifuge at a speed of 4200r / min for 10min, and the upper layer was removed. solution, separated to obtain the lower precipitate, put the lower precipitate into a vacuum drying oven with a set temperature of 80 °C, and dry for 12 h to obtain surface-modified titaniu...

example 2

[0025] Mix 210mL of absolute ethanol with 110mL of 2% perfluorooctyltriethoxysilane aqueous solution to obtain a siloxane solution, adjust the pH of the siloxane solution to 3.1 with 60% acetic acid, and dissolve the silicon Pour the oxane solution into a beaker, stir and mix with a magnetic stirrer at a speed of 310r / min for 23 hours to obtain a hydrolyzed fluorosilane solution; prepare a titanium dioxide ethanol mixture with a mass concentration of 4 mg / mL, mix the titanium dioxide ethanol mixture with the hydrolyzed The fluorosilane solution was mixed at a volume ratio of 4:1, placed in a beaker, stirred and mixed with a magnetic stirrer at a speed of 420r / min for 7.5h, and then placed in a high-speed centrifuge at a speed of 4300r / min for 11min to remove The upper layer was separated to obtain the lower precipitate, and the lower precipitate was placed in a vacuum drying oven with a set temperature of 82 °C, and dried for 13 hours to obtain surface-modified titanium dioxide...

example 3

[0027] Mix 220mL of absolute ethanol with 120mL of 2% perfluorooctyltriethoxysilane aqueous solution to obtain a siloxane solution, adjust the pH of the siloxane solution to 3.3 with 60% acetic acid by mass fraction, and Pour the oxane solution into a beaker, stir and mix with a magnetic stirrer at a speed of 320r / min for 24 hours to obtain a hydrolyzed fluorosilane solution; prepare a titanium dioxide ethanol mixture with a mass concentration of 4 mg / mL, mix the titanium dioxide ethanol mixture with The hydrolyzed fluorosilane solution was mixed at a volume ratio of 4:1, placed in a beaker, stirred and mixed with a magnetic stirrer at a speed of 450r / min for 8 hours, and then placed in a high-speed centrifuge at a speed of 4500r / min for 12min. Remove the upper liquid, separate the lower precipitate, put the lower precipitate into a vacuum drying oven with a set temperature of 85 °C, and dry for 14 h to obtain surface-modified titanium dioxide nanoparticles; toluene, isophorone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com