Multi-layer graphene carbon nanotube three-dimensional carbon material-filled nanometer silicon composite material and preparation method thereof

A technology of multi-layer graphene and multi-wall carbon nanotubes, which is applied in the field of materials, can solve the problems of electrochemical performance attenuation, large volume change, active material shedding, etc., and achieves improved transfer speed, improved rate performance, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

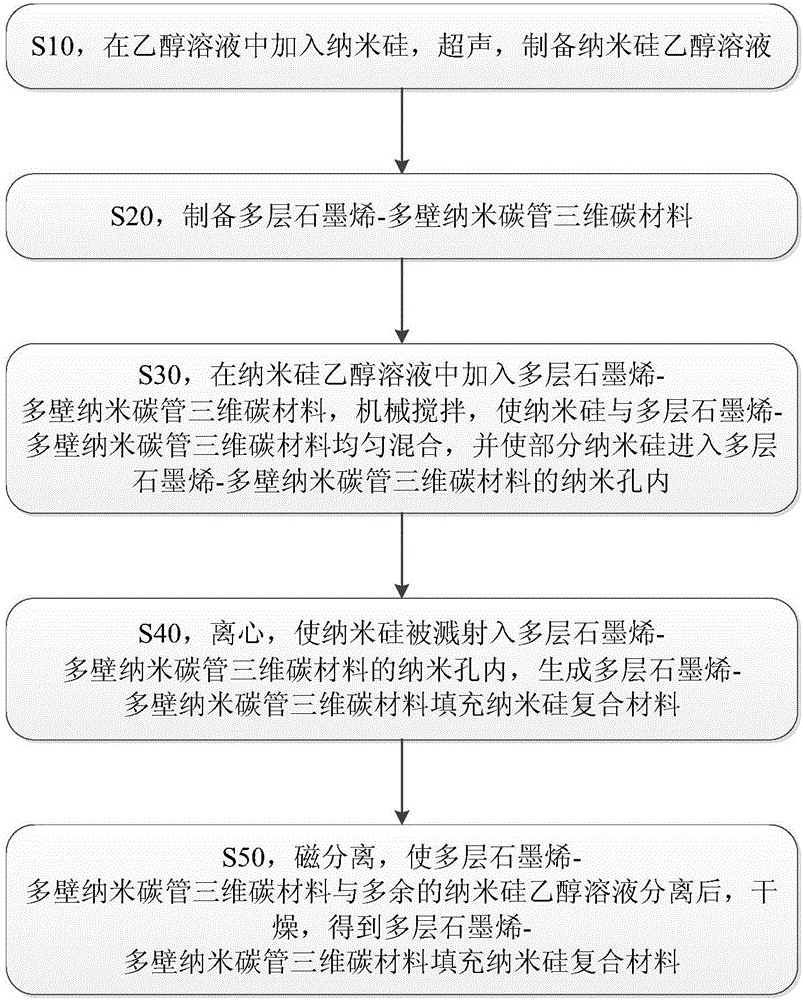

[0041] see figure 1 , which is a flow chart showing the steps of the preparation method of the multilayer graphene-multi-walled carbon nanotube three-dimensional carbon material filled nano-silicon composite material according to the embodiment of the present invention, which includes the following steps:

[0042] S10, adding nano-silicon into the ethanol solution, and ultrasonicating to prepare a nano-silicon ethanol solution. Specifically, the ratio of the mass of nano-silicon to the volume of ethanol solvent is 0.1-2.0 mg / mL, and the ultrasound is performed for 0.5-2 hours.

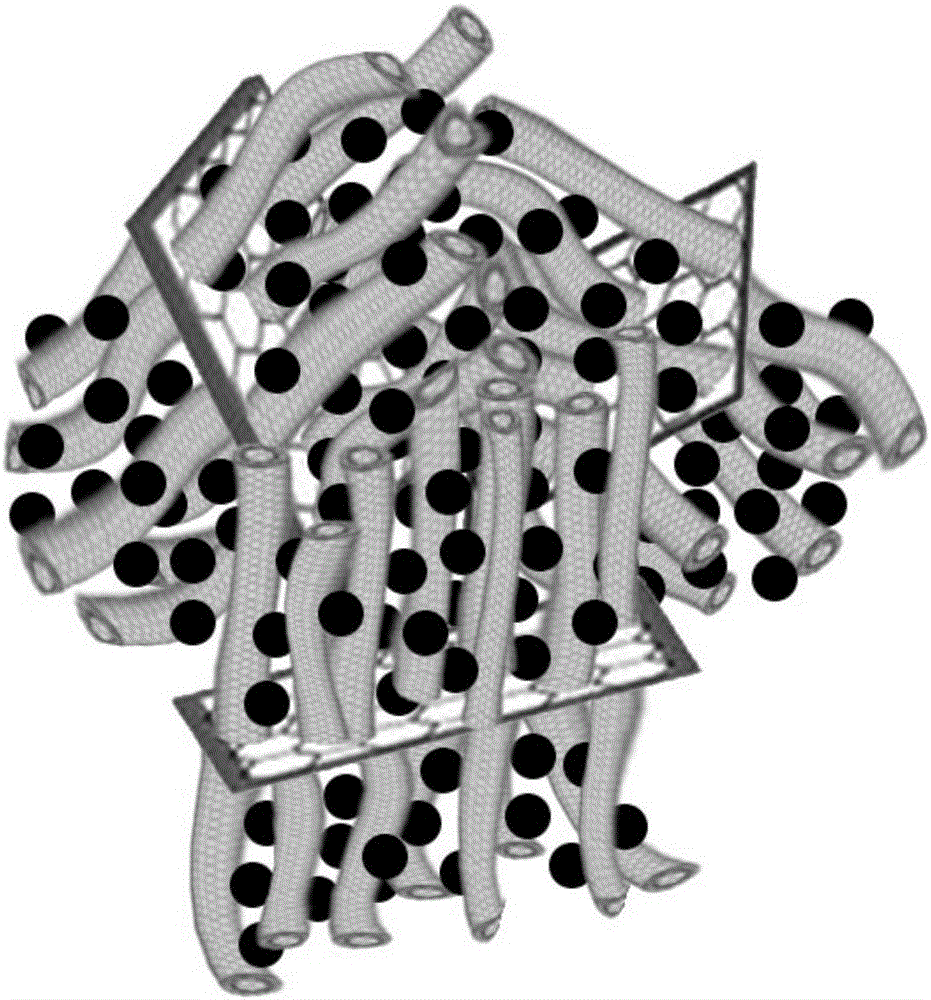

[0043]S20, preparing multi-layer graphene-multi-wall carbon nanotube three-dimensional carbon material. Specifically, S201, measure DMF and distilled water with a volume ratio of 8:2-9:1, mix them as a mixed solvent, and use the volume of the two as a mixed solvent for calculation; S202, add expanded graphite, and ultrasonically vibrate for 2- After 7 hours, multi-layer graphene is obtained, the numb...

Embodiment 1

[0050] The preparation method of the multilayer graphene-multi-walled carbon nanotube three-dimensional carbon material filled nano-silicon composite material according to the embodiment of the present invention comprises the following steps:

[0051] S10, adding nano-silicon into the ethanol solution, and ultrasonicating to prepare a nano-silicon ethanol solution. Specifically, the mass of nano-silicon is 2 mg, the volume of the ethanol solution is 10 mL, the ratio of the mass of nano-silicon to the volume of the ethanol solvent is 0.2 mg / mL, and ultrasound is performed for 1 h.

[0052] S20, preparing multi-layer graphene-multi-wall carbon nanotube three-dimensional carbon material. Specifically, S201, measure DMF and distilled water with a volume ratio of 8:2, mix them as a mixed solvent, and the volume of the two and the volume of the mixed solvent are used for calculation; S202, add 20 mg of expanded graphite, and ultrasonically oscillate for 3 hours to obtain more layer...

Embodiment 2

[0058] The preparation method of the multilayer graphene-multi-walled carbon nanotube three-dimensional carbon material filled nano-silicon composite material according to the embodiment of the present invention comprises the following steps:

[0059] S10, adding nano-silicon into the ethanol solution, and ultrasonicating to prepare a nano-silicon ethanol solution. Specifically, the mass of nano-silicon is 3.3 mg, the volume of ethanol solution is 10 mL, the ratio of the mass of nano-silicon to the volume of ethanol solvent is 0.33 mg / mL, and the ultrasound is performed for 0.8 h.

[0060] S20, preparing multi-layer graphene-multi-wall carbon nanotube three-dimensional carbon material. Specifically, S201, measure DMF and distilled water with a volume ratio of 8.5:1.5, mix them as a mixed solvent, and the volume of the two and the volume of the mixed solvent are used for calculation; S202, add 15 mg of expanded graphite, and ultrasonically vibrate for 2 hours to obtain more la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com